We wrote about the chimney effect in the first part. However, this air flow alone is not enough, and you have to work on the air flow with a lot of waste heat. For this purpose, so-called housing fans are used, which in turn can differ by a large number of characteristics. Above all, the correct selection and design of the fans will later determine cooling performance and sound scenery. Even if air flow and noise are directly related – there are some rules to achieve as much throughput as possible with the lowest possible noise. But a little later more on that.

Big or small?

The size of the fan to be used is of course almost always specified by the housing and the holes in it. For such fans, there are therefore common standard sizes. We are only interested in the sizes of 60, 80, 92, 120 and 140mm, larger fans are usually already firmly installed in the housings. Of course, a fan is primarily there to generate an airflow using a fan wheel similar to an aircraft propeller. The logic here already leads to two conclusions: the faster a cooler rotates and the larger it is, the more air can be transported – which in turn can produce unpleasant and disturbing noises.

Generally speaking, however, one can say that the slower a fan rotates, the quieter it is. The resulting loss of power is then compensated by the size. Key message: a large, slow-rotating fan is preferable to a smaller, fast-rotating fan at any time. This is why the usual fan sizes of current housings are 120mm and, more recently, 140mm. Smaller 80mm fans should be avoided as much as possible for noise reasons. This is also important when buying a new housing. However, in the chapter on fan recommendations, we will also introduce a low-priced 80mm fan, which could provide a relief for the ears, at least for retrofitters.

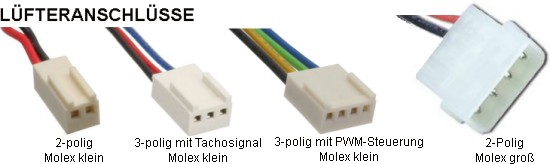

Fan connection and control

The fans may be controlled or unregulated. You can already see the possibilities of a possible control on the respective fan plugs. We will later go into more detail about the voltages and possibilities of reassignment in order to influence the speeds with simple means. In general, however, all housing fans are operated with 12 volt connection voltage. This is provided directly by either the motherboard or the power supply. So-called power fans with more than 2 watts of power should always be fed directly from the power supply.

Here the large Molex plugs are used, where only 2 poles of the actual 4 poles are occupied: mass and 12 volts. The smaller, so-called “fan plugs” are also actually Molex plugs, but in smaller versions (the namesake here is also the company Molex, which created a standard for such plugs). These smaller connectors are designed for connection to the motherboard or fan controllers.

The small plugs in the 3-pin version still contain the return of the so-called speedometer signal in order to be able to read out the speed. 2- and 3-pin connected fans can only be controlled by changing the voltage. 4-pin fans are mainly used for CPU coolers, where the speed can be controlled from the outside with the help of the so-called PWM (pulse width modulation) (e.g. temperature-dependent).

What is throughput?

Simple answer: the amount of air that can be transported by the fan in a given time. This information is therefore a very important feature for us. Unfortunately, different units are used for this information, which can confuse laymen in particular. In English (and most manufacturer’s data) the specification in cfm (cubic foot per minute) is used more often, while in German trade m3/h (cubic meters per hour) is used. So the mess is almost complete. We don’t want to get bored with the complete calculation path, but offer the reader a simple comparison and conversion aid. So here is the simplified conversion table:

| Output | Conversion factor | Target |

|---|---|---|

| 1 m3/h | x 0.58867 | 0.58867 cfm |

| 1 cfm | / 0.58867 | 1.69874 m3/h |

Calculation example:

In keeping with the summer, we buy a table fan with a throughput of 840 m3/h in a German electric market. What is the equivalent value of the US manufacturer in cfm? We calculate logically: 840 x 0.58867 =494.4828. Congratulations! So we see that in principle it is not that difficult

How do fan noises occur and what is it?

Noises are usually a colorful frequency mixture and therefore actually very difficult to define exactly. If one looks at the technical data of the fans, the so-called sound level of the fan in operation in dB (decibel) or dB(A) or in Sone (loudness). Disadvantage of these values: you still don’t know how such a fan really sounds in operation. Whether and how to find a noise disturbing is decided by many factors. Light noise, buzzing engine, bearing noise? A fan with a lower sound level can therefore appear in some cases quite unpleasant than the supposedly “louder”.

It’s certainly a big noise here! Especially the rotor blades (blades) of a fan contribute to the background noise. Depending on the quality of the design and the speed, more or less pronounced demolition noises are produced at the leaf edges. In addition, the surface, position of the leaves (steepness) and their number actively affect the sound level. Corrugated leaf edges and leaf shapes, golf ball design and other gimmicks are expected to contribute to lower noise in some manufacturers. In addition, air vibrations can be caused by propellers rotating too close to grid covers and apertures, and the so-called “siren effect” is then obtained.

Sliding or ball bearings. Or what else?

Additional noises can come from the drive and are often annoying, especially at lower speeds, because “buzzing”. Grinding or crackling bearing noises are also not so easy to put into numbers, but they also have a superficially disturbing effect. Ball bearings run slightly lighter than plain bearings and usually have a fairly useful service life depending on lubrication/storage. However, if these fans are provided in cheap versions with only a single ball bearing, then due to the rotational movement and the air turbulence additional unintended transverse forces arise, which promote wear and lead to the dreaded ” clatters”.

Let’s open a fan and see a typical, very simple plain bearing. Not very quiet, but even repairable in an emergency.

Double ball-bearing fans do not know this problem. However, plain bearings are usually even slightly quieter and in the design as ceramic bearings they also have the greatest service life, because ceramic has by far the lowest friction resistance with the appropriate surface quality. In general, however, one should prefer good ball-bearing fans to those with simple plain bearings, whereby with double ball-bearing fans one gets the best compromise of volume and durability. As always, the rest is a matter of faith, because the boundaries are blurred in high-quality speeches. We now see a diaphragtrail fan with ball bearings. If this is tight, the fan is a case for the ton.

However, we do not want to give a lecture on aerodynamics and mechanical engineering. In addition, there are other types of bearings that can be driven by the manufacturers’ films in a marketing-effective way. However, they are similar in principle, even if, for example, various liquids are used. Whether liquid storage or other “inventions” are advertised, often the best solutions are not the most expensive and expensive in the end. The resulting throughput is therefore in relation to the volume and the sound impression of the quality of the product. The lower the latter values at the highest possible throughput, the more suitable the product will be for our use.

- 1 - Einführung und Übersicht

- 2 - Unter- oder Überdruck? Wir wägen ab!

- 3 - Netzteilpositionierung: Oben oder unten?

- 4 - Airflow: Towerkühler senkrecht montieren

- 5 - Airflow: Towerkühler waagerecht montieren

- 6 - Airflow: Beliebte Montagefehler

- 7 - Airflow: Downblower-Besonderheiten

- 8 - Airflow: Festplattenkühlung

- 9 - Airflow: Grafikkarten richtig belüften

- 10 - Gehäuselüfter: Wissenswerte Grundlagen

- 11 - Unangenehm: Körperschall und Resonanzen

- 12 - Lüftersteuerung, Zusammenfassung und Fazit

76 Antworten

Kommentar

Lade neue Kommentare

Urgestein

Veteran

Urgestein

Urgestein

Urgestein

Urgestein

Veteran

Veteran

Veteran

Urgestein

Veteran

Veteran

Urgestein

Mitglied

Urgestein

Veteran

Mitglied

Veteran

Veteran

Alle Kommentare lesen unter igor´sLAB Community →