Disassembly and radiator details

Removing the top hee cover is easy. With a small Phillips screwdriver (PH1), the six small swivels that hold this cover can be turned out. After that, the interior with the actual cooler and the large mounting or Cooling frame free.

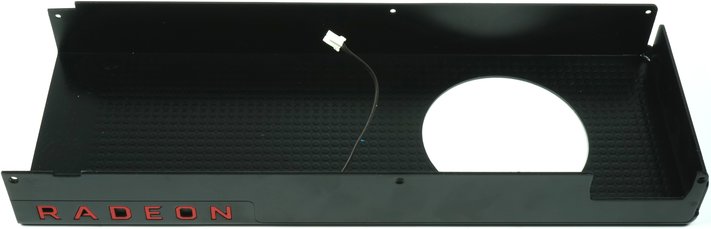

AMD is again relying on the Direct Heat Exhaust (DHE) principle for this card, which does not have to be a disadvantage. We see the radial fan in the suction chamber and the path of the air, longitudinally through the block of the chamber cooler up to the slot panel (right).

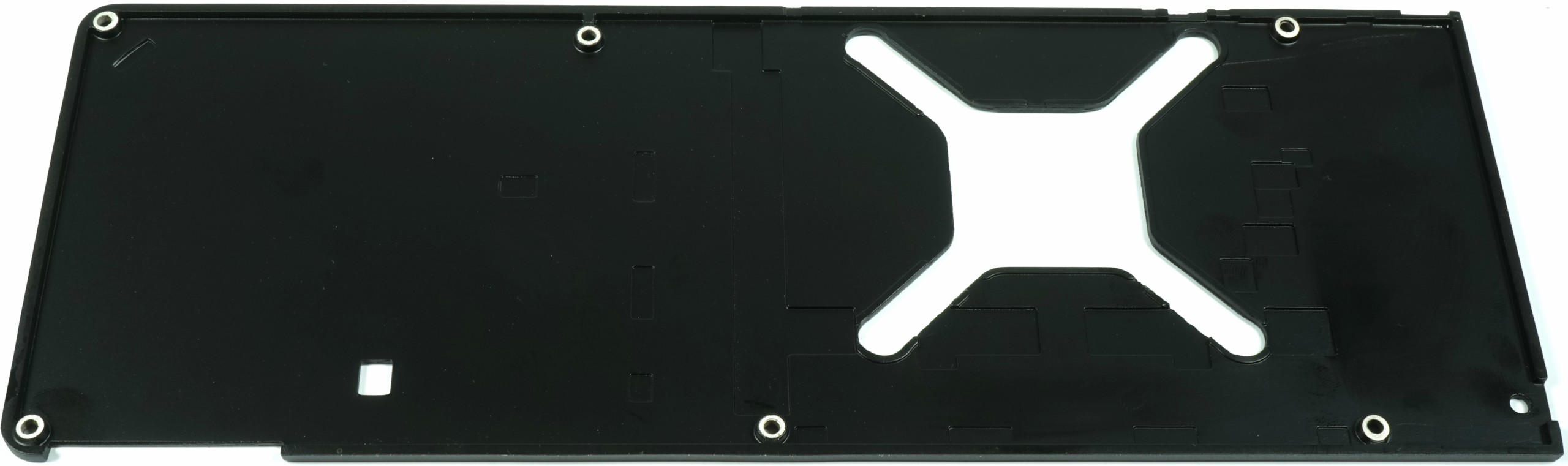

The backplate made of black anodized aluminium, which is fastened with six screws, has only an optical function, because it does not contribute to cooling. Attempts to dissipate additional heat using thermal lyre pads, except for slightly cooler doubler chips, yielded hardly measurable results, as with the Vega Frontier Edition.

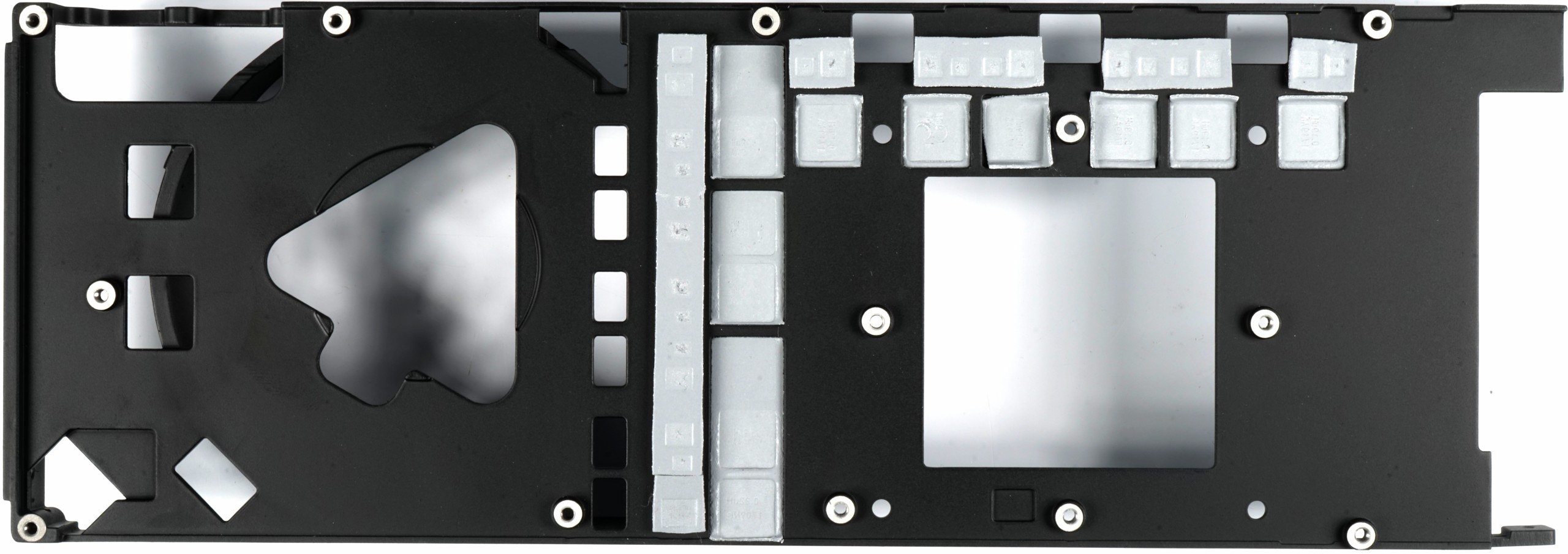

On the top of the board sits the massive mounting or Cooling frame, which on the one hand holds the entire structure together and on the other hand also represents an important cooling element. The design has learned, because similar to Gigabyte (Aorus) on the GTX 1080 Ti Xtreme Edition, you also rely on relatively well thermally conductive coil housings, which are also cooled by thermal lyre pads, similar to the VRM of the voltage converters. even the appropriate recesses. We will see later that this works well.

|

|

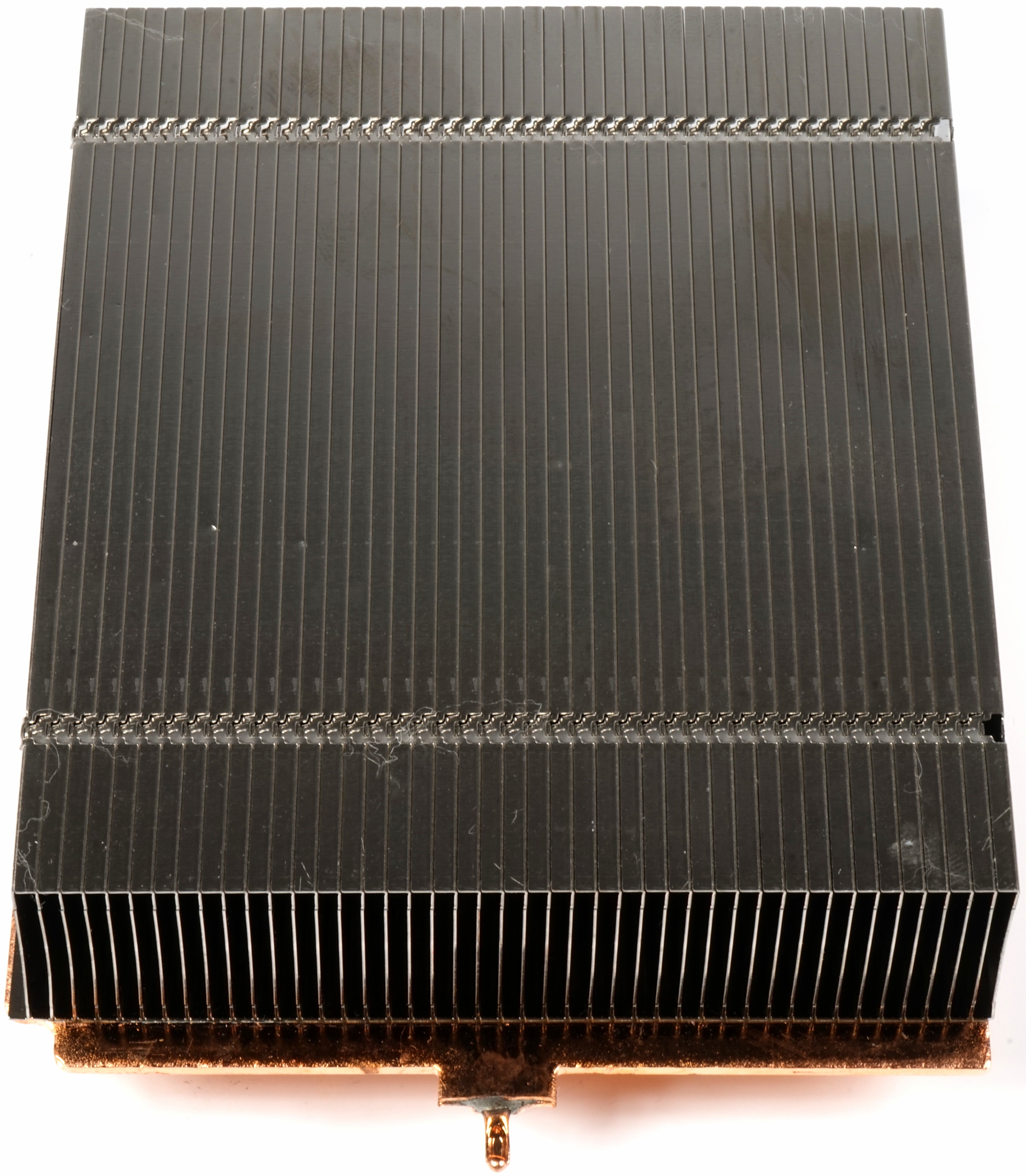

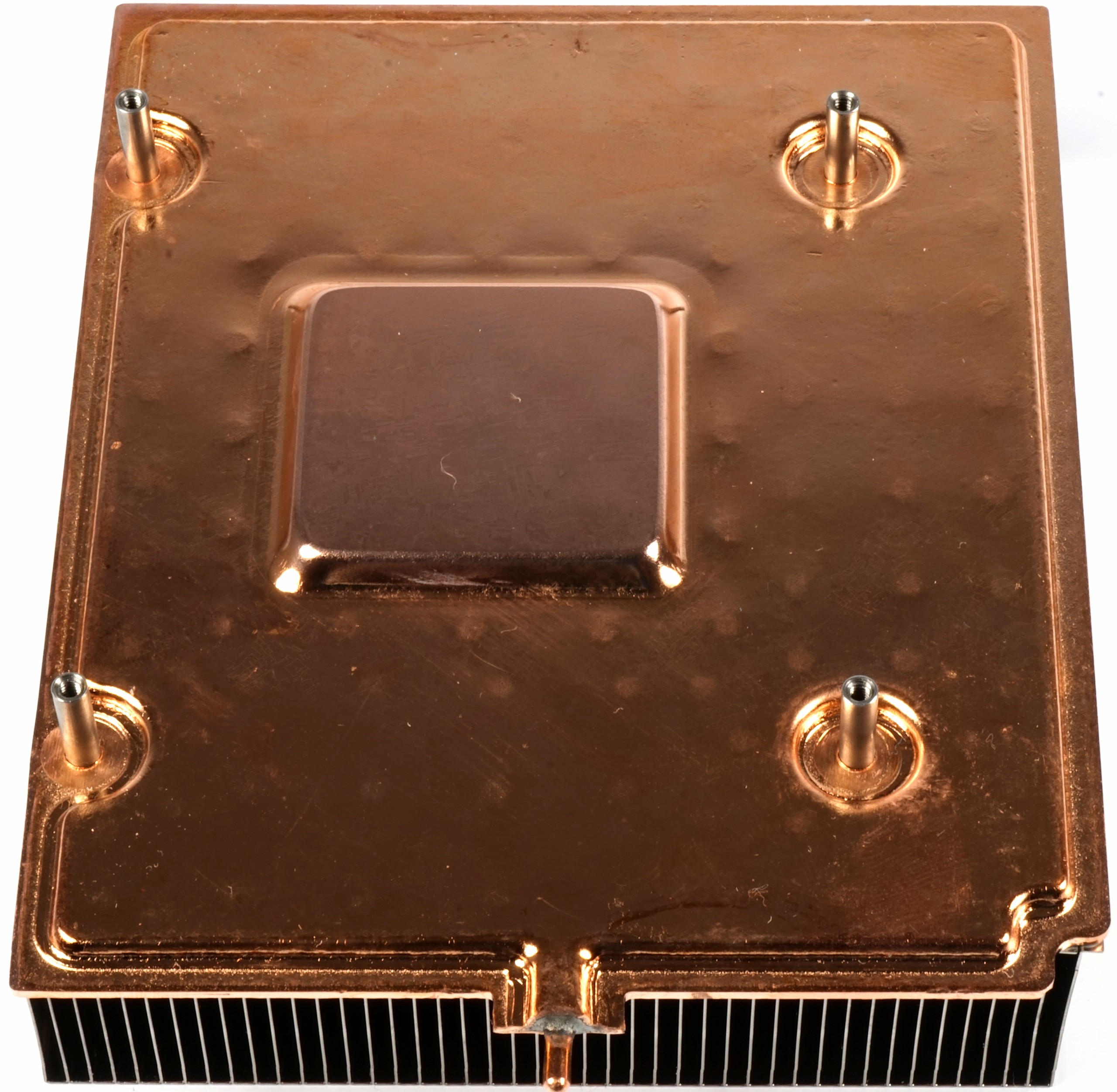

The actual chamber heat sink as a thin aluminium fin sits on a large vapor chamber made of copper. One sees the soldered outlet of the one-piece hybrid vapor-chamber (One Piece), which one must not bend down. The moulded heat sink is adapted to the package in size

|

|

For the 7cm radial fan, AMD is relying for the first time on a single ball-bearing model from Delta and not one of the snarling and far too loud examples of the reference predecessor models. Compared to the previously up to 10,000 rpm, the extra-strong fan of the BVB1012 series only rotates up to a maximum of 5,000 rpm. AMD sets the fan target to approx. 40% to 41%, which is then equivalent to about 2,000 rpm. We'll see that the sound characteristics are now more like what Nvidia can offer on their Founders Edition.

|

|

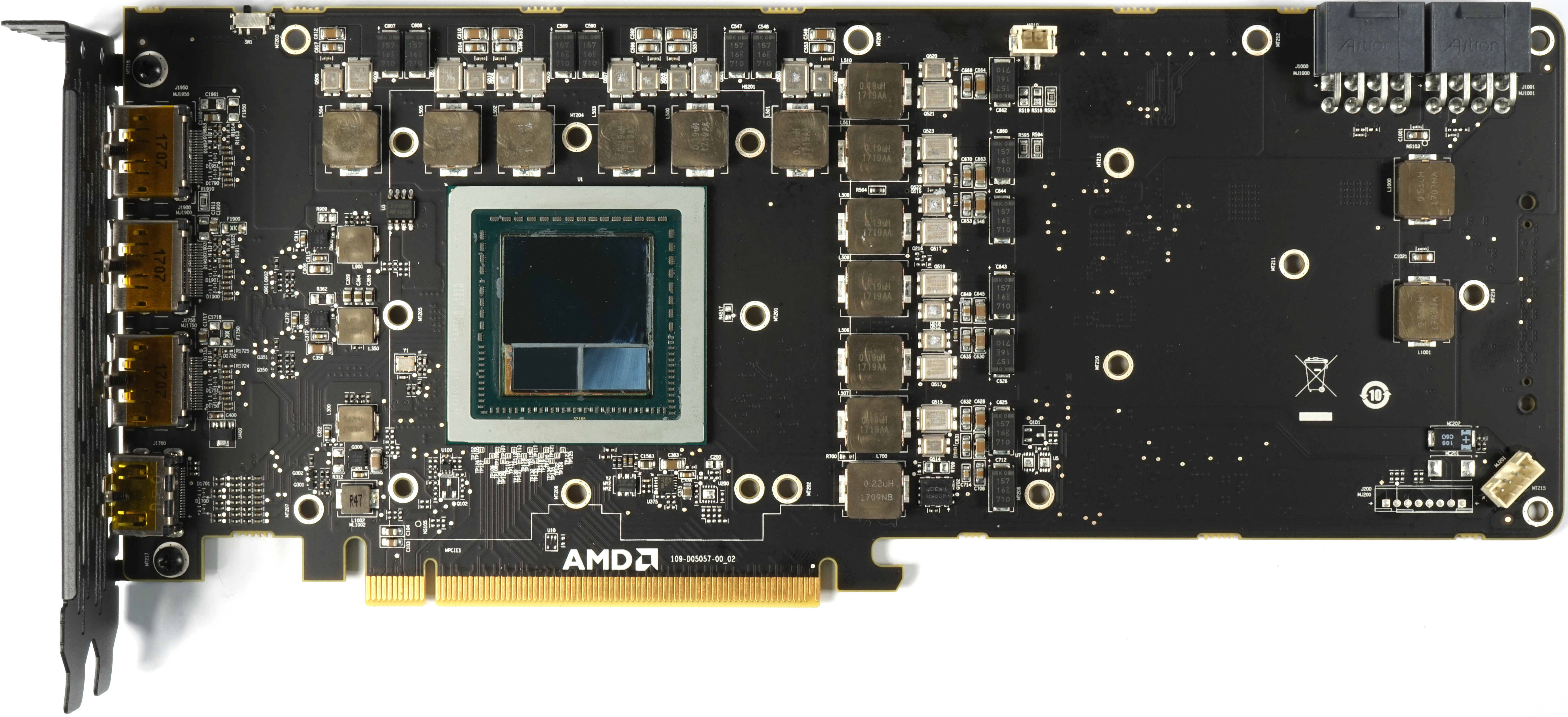

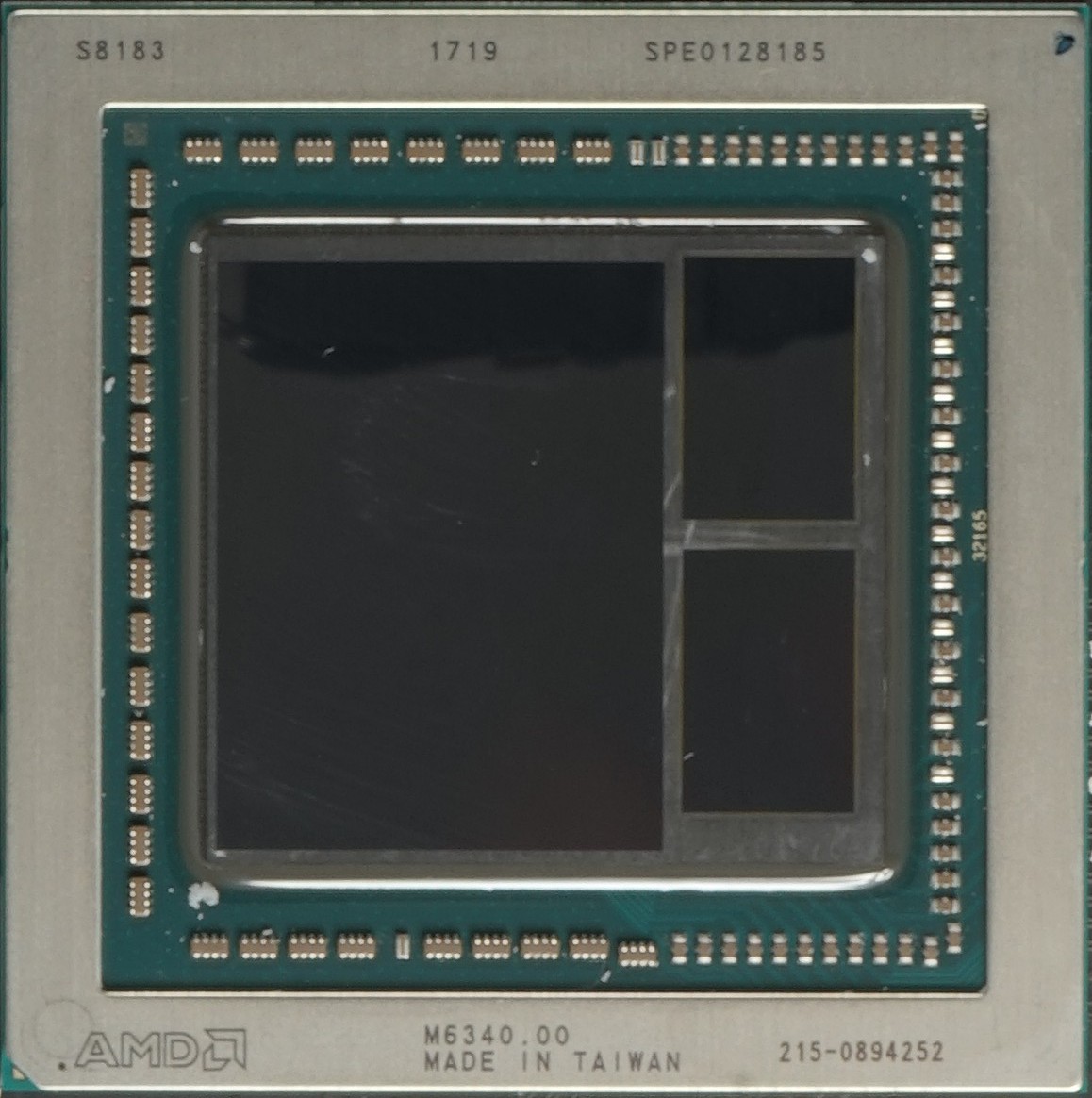

The completely exposed board shows on the front as the dominant element the this time unolded package with the big interposer, which we will talk about in a while. The exact board analysis can then be found in the next chapter

The package: confusing play and problems for manufacturing

Since the GPU (and in this case also the interposer with GPU and memory) cannot be soldered so easily onto the PCB, these components are first used by one of the specialized finishers (e.g. ASE) on a so-called package ("packaging process"), which can later be processed much more easily in the factories. To do this, it is important to know that these packages are fed by machine from a roll on a transfer belt in the SMT process and then positioned on the PCB. So far so good.

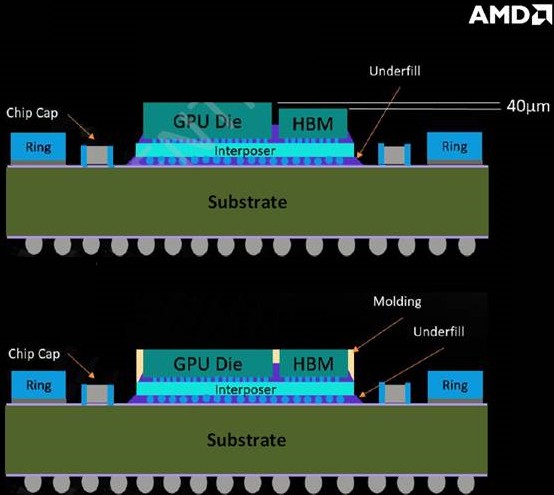

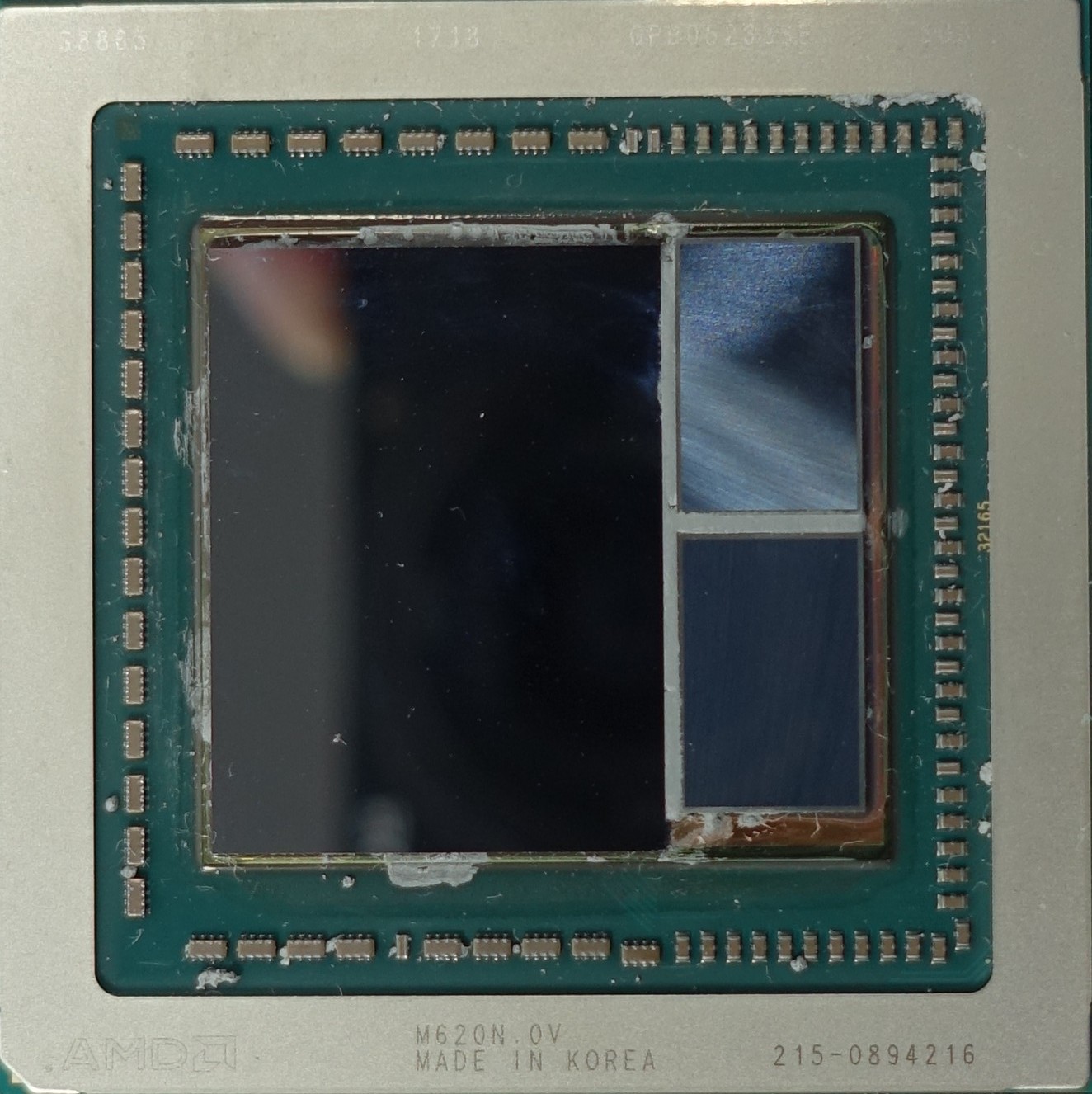

But let's first compare the package as it was initially used on AMD's internal slides and demonstrations (left image below) and as we now (unfortunately) also find it on our RX Vega56. We can see that there are deeper gaps between the GPU and the two memory modules, as in Fiji, respectively. these components are relatively high. The interposer, on the other hand, is extremely thin and, above all, fragile. Hence the warning to the internal lyre to take care of the removal of old thermal paste during the development phase.

Upper scheme: unemoldet, lower scheme: gemoldet

Upper scheme: unemoldet, lower scheme: gemoldet

For a machine production, such a thing is of course also quite risky, especially since one can also encounter so-called "underfill" problems, since in packaging also pressure-sensitive cavities can always form between the interposer and the intermediate board. However, if you look at the package currently used on the Vega FE and some RX Vega (right picture below), you can clearly see that AMD relies on the so-called molding here. The area around GPU and memory has been poured over a large area with a suitable material, which significantly increases stability.

|

|

Nevertheless, AMD is currently demonstrably using both versions of the packaging, which also come from two different finishers, which poses further problems for AMD's board partners. In the past, for example, It was partly the case at Fiji that AMD sent only the working chips to SK Hynix and they installed functional HBM modules, had the packaging done unemoldet immediately in Korea, and only then the finished package returned to AMD. was sent. The gemed packages on our two previously tested maps, on the other hand, come from ASE in Taiwan.

But where is the problem? Since the unolded packages of the HBM2 are 40 microns lower and the underfill also differs somewhat, but the entire package can be up to 0.1 mm higher (!), further unexpected problems and delays arise in the production of the custom designs. Apart from the problems with the SMT process, the custom coolers cannot be used without further adjustments.

We have information that individual partners now have to fix the radiator heatsinks with six instead of four screws and accordingly all previously prefabricated heat sinks and backplates are unusable for the unfinished packages. have become or/or need to be modified again.

There are also various problems with the pre-applied thermal conductive pastes, their viscosity and layer thickness. What was still optimal with gemoldee packages can be too little contact with unolded ones. In addition, the contact pressure can vary, which poses extreme challenges for mixed production, because the AIB never knows what it will end up delivering. We will, of course, continue to pursue this issue.

- 1 - Einführung und Übersicht

- 2 - Kühler und Package

- 3 - Platinendesign und Detailinformationen

- 4 - Mining, VR: Arizona Sunshine und Chronos

- 5 - VR: Dirt Rally, Robo Recall und Serious Sam

- 6 - Ashes of the Singularity: Escalation

- 7 - Battlefield 1

- 8 - Warhammer 40.000: Dawn of War

- 9 - Doom (2016)

- 10 - Tom Clancy's Ghost Recon Wildlands

- 11 - Hitman (2016)

- 12 - Metro Last Light (Redux)

- 13 - Tom Clancy's The Division

- 14 - The Witcher 3 Wild Hunt

- 15 - Leistungsaufnahme mit acht verschiedenen Settings

- 16 - Übertaktung, Untertaktung, Effizienz und Temperaturen

- 17 - Lüfterdrehzahlen und Lautstärke

- 18 - Zusammenfassung und Fazit

Kommentieren