Construction of the delid tool

Now let’s have a look at the delid tool, which is used to “behead” the CPU. This is needed to effectively separate the glued and soldered IHS from the package and die of the CPU with a precise shearing motion. Such a delid tool should therefore be manufactured accordingly precise and exact in order not to damage or even destroy the CPU. Because often the smallest error here means silicon death.

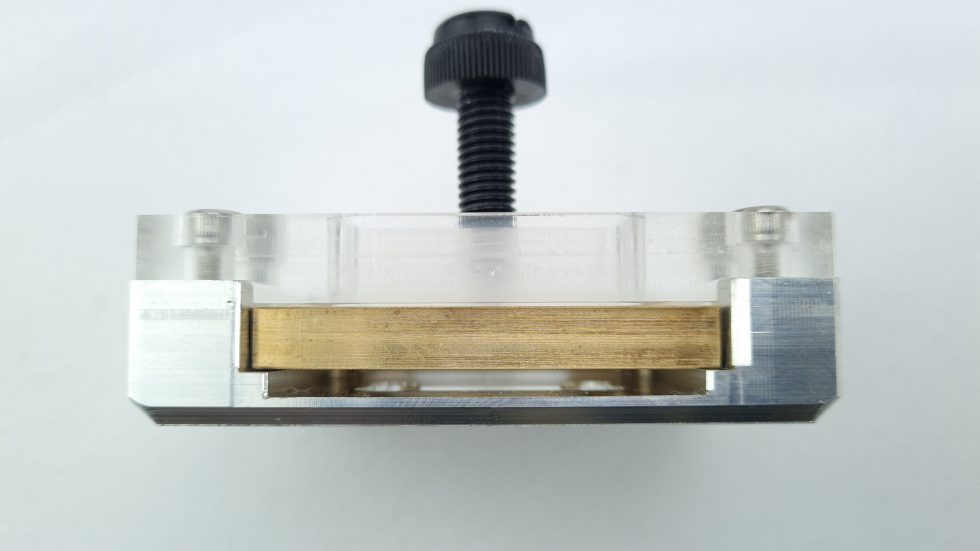

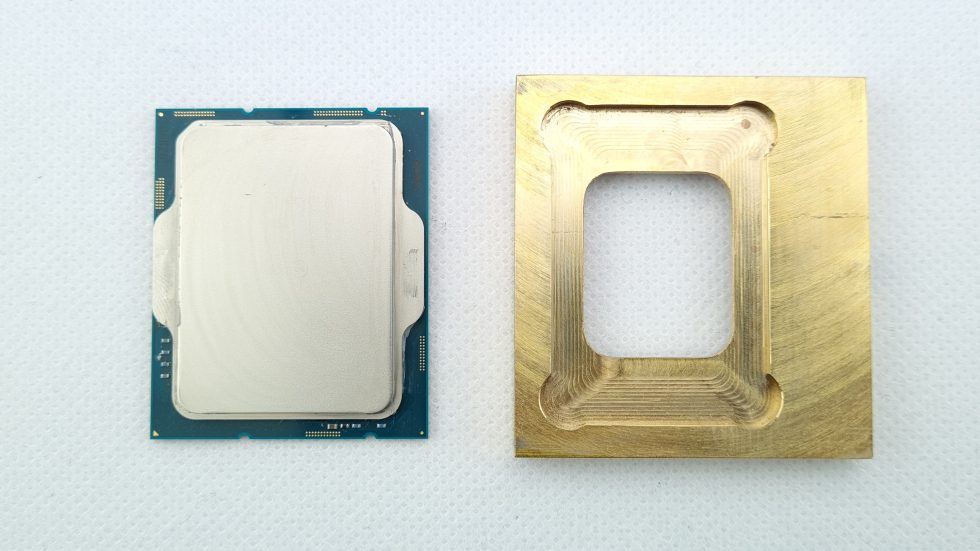

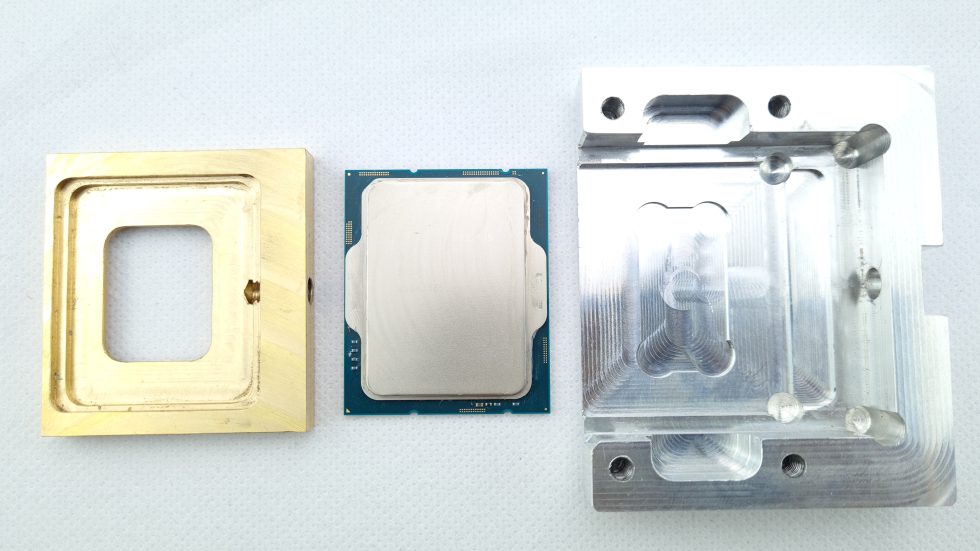

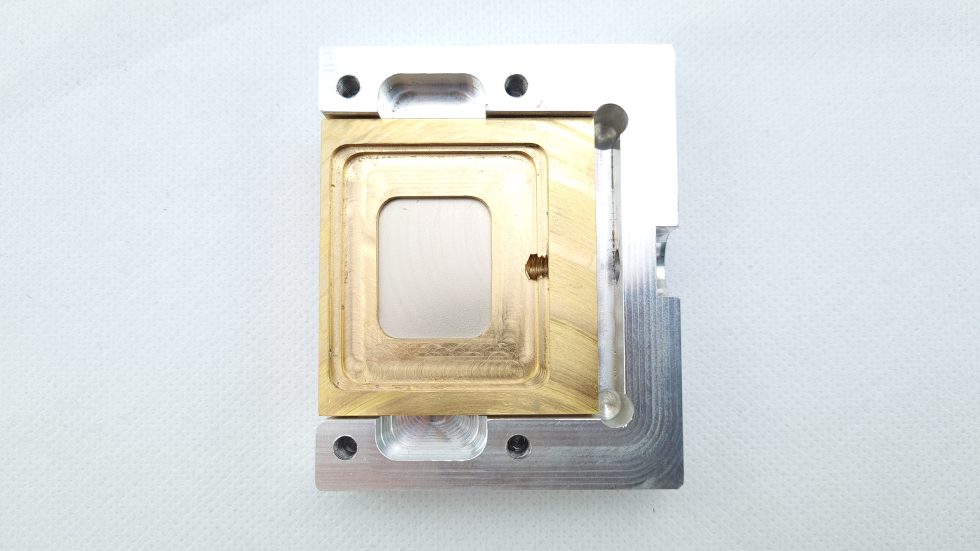

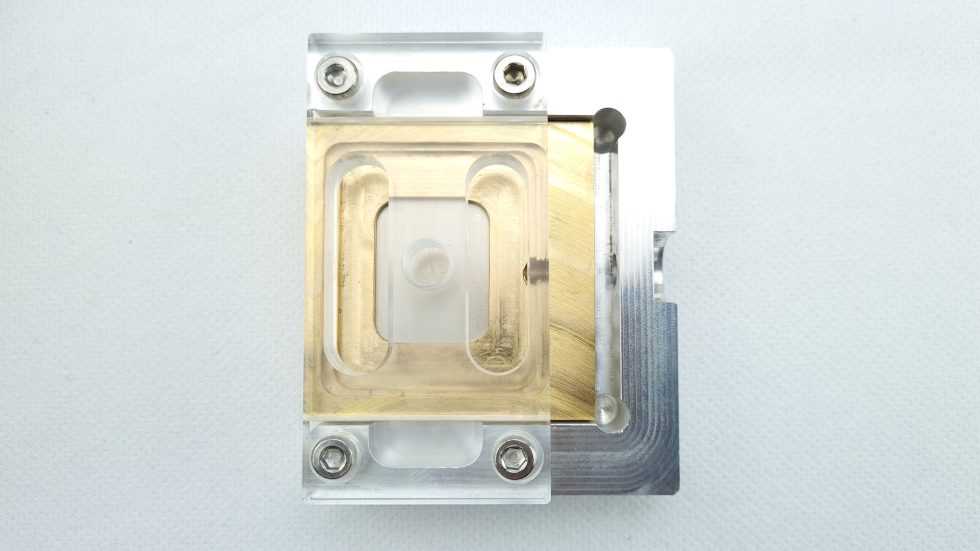

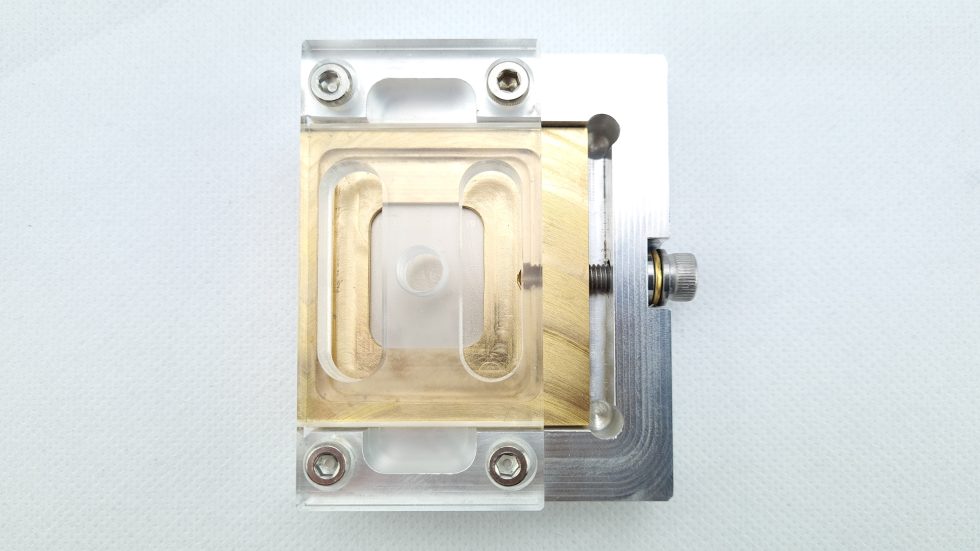

At first glance, the tool is somewhat reminiscent of a Frankenstein-like construction, with components made of aluminum, brass and acrylic, held together by four hexagon socket screws, this time M4 with 3 mm heads. A black plastic screw clamp is integrated at the top center, which can be used to fix the IHS in place if it is glued again later.

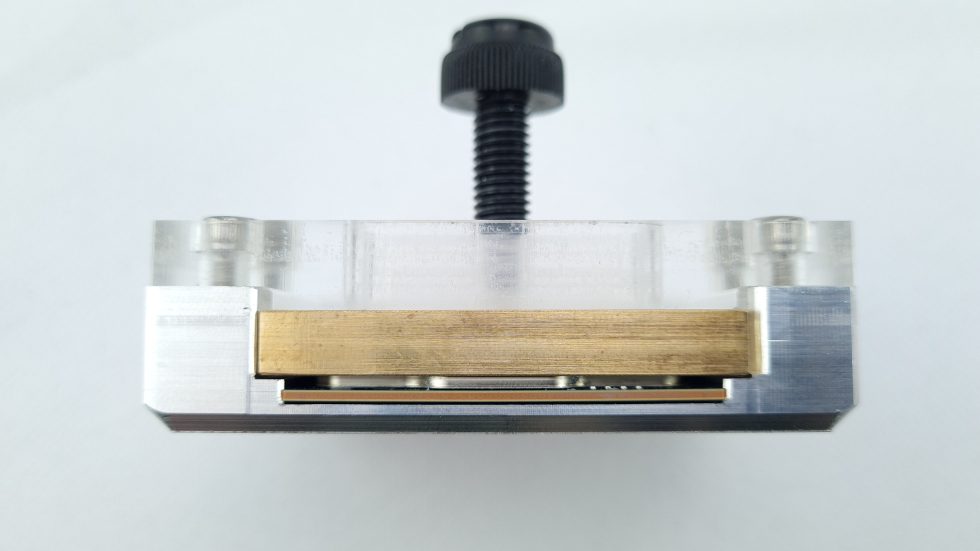

From the side, you can see how the brass part is effectively a kind of slide in the outer aluminum part and at the same time is held at the right height by the acrylic part. Unfortunately, the manufacturing is not really 100% precise for my German understanding with about a millimeter of play on the side and half a millimeter upwards.

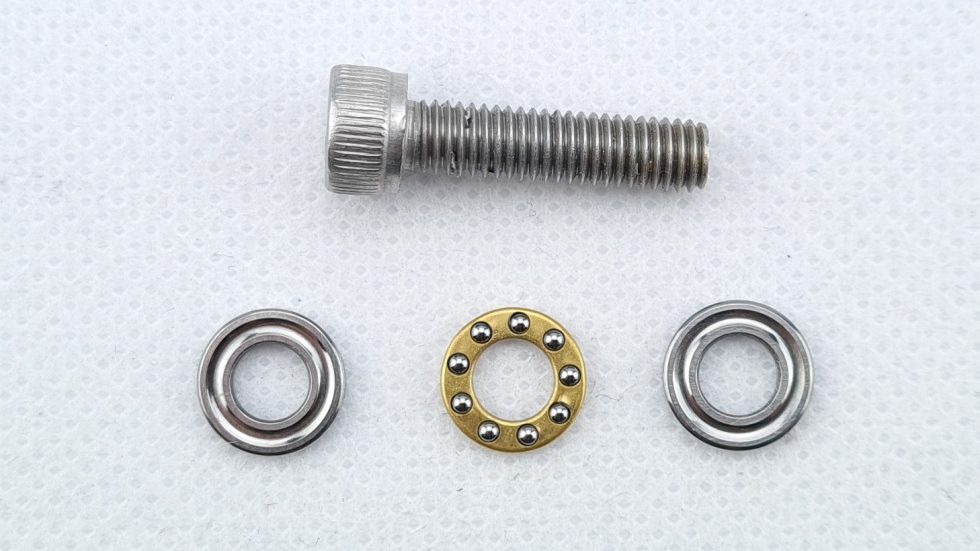

The actual shearing motion is provided by an M5 ball bearing screw with a 4 mm Allen head, which is designed to pull the slide toward it from the side of the tool.

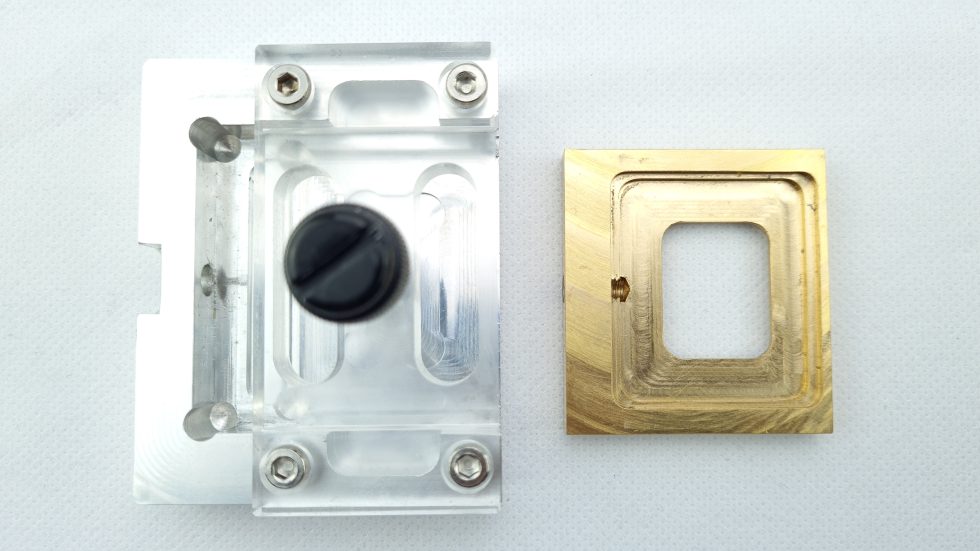

After removing the screw, the brass slide can be easily pulled out. This has a two-step milling from the top, which can be used to align the IHS for re-gluing.

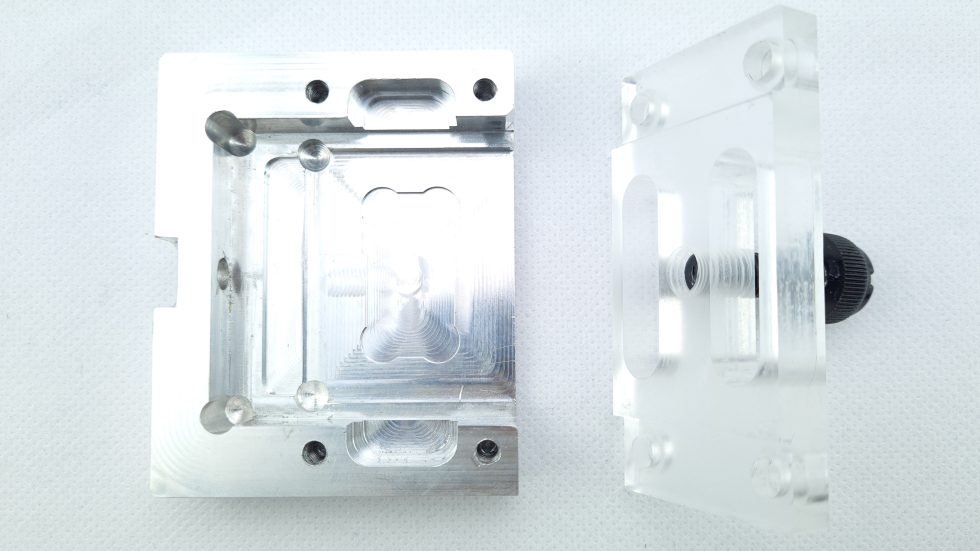

If we now remove the acrylic element, the really important milling for locking the CPU for the Delid process is revealed. First, we find the seat for the CPU with effectively the same dimensions as an LGA1700 socket. The two inner corners are drilled out, probably to prevent damage to the CPU there. Another recess is integrated in the center of the CPU seat, into which the tiny SMD components on the bottom of the CPU can protrude without contacting the tool.

Here in particular, there are still sometimes clear traces of production, chips and lubricants that should be removed beforehand. So I took the few minutes and cleaned the part once as best I could first with a brush and then 99% isopropanol. After all, nothing would be more annoying than pressing an aluminum tap into the package during delidding. Supercool Computers would do great to improve here a bit after production to avoid unnecessary hassle for customers.

Unfortunately, there are no real instructions from the Thai manufacturers on how to use the Delid tool or water block, at least not as you would probably expect. In the above linked Youtube Livestream VOD of Clock’em Up! the manufacturer has at least shown the procedure itself, with a Thai explanation, but at least the basics like the orientation of the tool parts can be recognized. I will then try to describe the decisive subtleties as accurately as possible in the following.

Off with your head! – Delidding

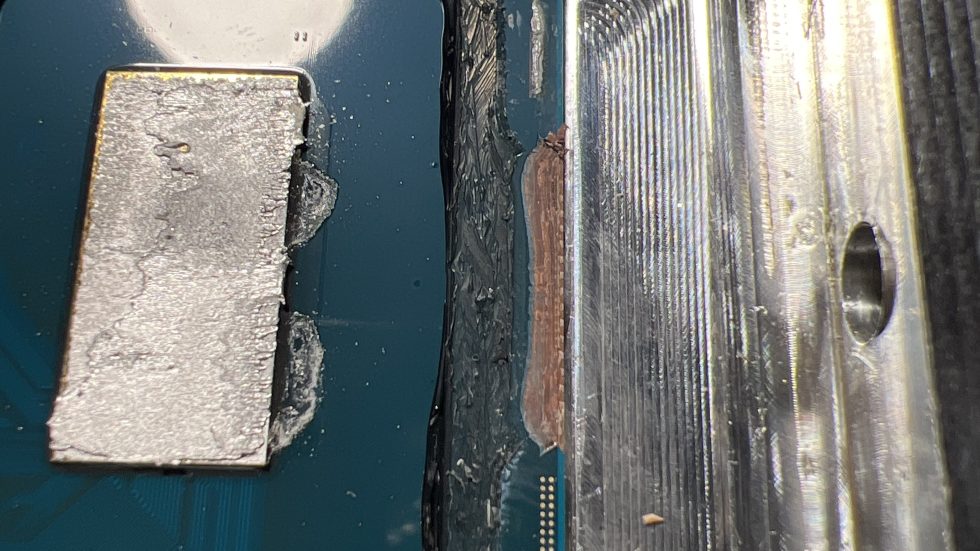

Now it’s time for the actual delidding or “beheading” of the CPU. Of course, this process cannot be reversed and will void the warranty. All of the following steps should therefore always be carried out exclusively at your own risk. Neither Intel nor Supercool Computers are liable for a dead CPU in any case. In the worst case, there doesn’t have to be any damage to the silicon die for the CPU to die. Even the smallest damage to the package or SMD components can be sufficient for this. Example:

Now this is not my first delidded CPU and so far everything always went well with me (knock on wood!), but with respect and caution one should always approach the matter nevertheless. And even then, there is always a certain remaining risk that you should be prepared for. But now I’ve scared you enough – let’s finally get started. For delidding, the side of the brass carriage with a single milling edge is used (not the one with two milling edges).

Before that, I put the CPU with its heatspreader upside down into the sled to check the fit. And indeed, the CPU fits here like a glove and almost sucks. A few thermal paste remnants from previous installation, which subsequently hung on the inner edge of the brass slide, are witness to the snug fit.

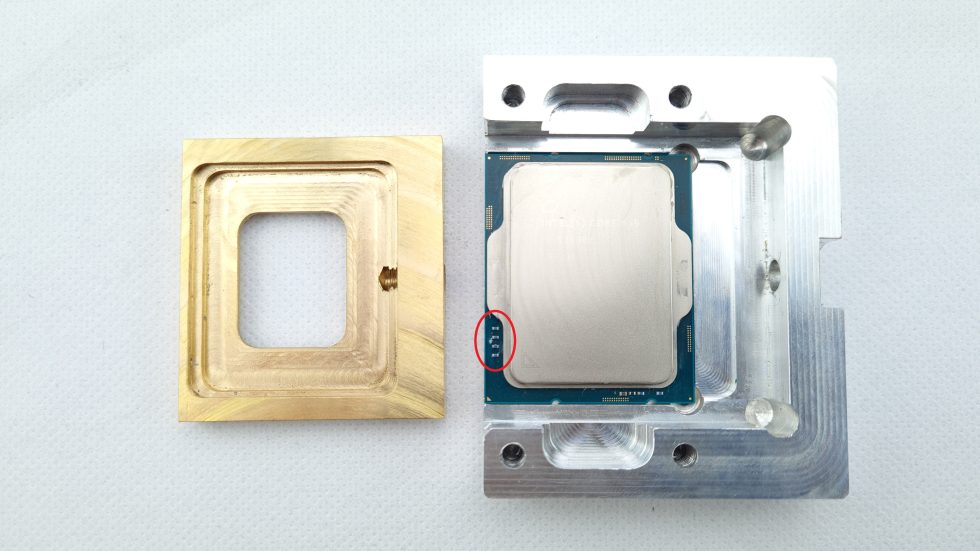

Now I’ve effectively flipped the sled and CPU once, so that the side with two edges is looking at us and the side with one edge is facing down. So we will put the parts in the aluminum part as well. But before that, it is still extremely important to pay attention to the correct orientation of the CPU.

That’s because it also has SMD components on the front, which would shear off if positioned incorrectly! So make sure that the SMD components on the long side of the CPU are on the open side of the aluminum part. Furthermore, of course, make sure that the CPU sits correctly in its recess and has no play upwards, downwards or to the right.

Now the brass slide is simply placed on the CPU. This should now sit fairly flush with the aluminum frame on the left and have a gap on the right. The heatspreader on the package is going to be moved towards this gap later.

Now it is still important to re-place the acrylic lid and screw it tight. This ensures that the sled is held flat on the heatspreader and cannot stand up.

From the side, you can see how the brass slide rests exactly on the ILM nose of the heatspreader, but does not exert any pressure yet. The acrylic lid holds the aluminum, package, IHS, brass sandwich in place vertically only. Just think away the black plastic screw clamp at the top – I hadn’t unscrewed it when I took this photo.

Now the only thing missing is the insertion of the large M5 screw including ball bearing and we can almost start with the delidding. Here, also pay attention to the orientation of the groved surfaces towards the ball bearing so that it functions correctly.

Now it’s time to get serious – insert the supplied 5 mm Allen key and carefully, slowly, but inevitably turn the screw vigorously until the heatspreader slowly moves on the CPU. Always check from the side and make sure that the sandwich layers just shown remain in position inside the tool. Whether the CPU survived, you can see on the next page!

56 Antworten

Kommentar

Lade neue Kommentare

Mitglied

Urgestein

Veteran

1

Urgestein

Veteran

Mitglied

Mitglied

1

Veteran

Moderator

Urgestein

Mitglied

Veteran

Urgestein

Veteran

Urgestein

Urgestein

Urgestein

Alle Kommentare lesen unter igor´sLAB Community →