Ever smaller manufacturing processes lead to ever higher thermal densities in CPUs and GPUs. This is one of the reasons why Intel’s new Alder Lake CPUs run so hot that every air cooler almost has no chance with a big i9, no matter how many watts of waste heat it is designed for. The often cited bottleneck lies further up the cooling chain, at the IHS and the heat-conducting layers that connect it to the silicon die and the coldplate of the cooler. Wouldn’t it be practical to simply eliminate this intermediate layer? Today, we are doing just that.

A big thanks in advance to Esenel and Ivano89 from the Intel Overclocking Discord, with whose help I can already test a finished retail sample of the Delid kit and Direct-Die waterblock today! The colleagues from Supercool Computers have also promised us a press sample, but this has so far been lost somewhere between language and logistics barriers. By the way, the kit can currently only be purchased through somewhat shady channels like Facebook, Twitter and Discord and with advance payment via Paypal. We will soon see whether the hardware makes a more reasonable impression. So let’s first take a look at what you get sent from Thailand for your 160 euros.

Scope of delivery and construction of the water block

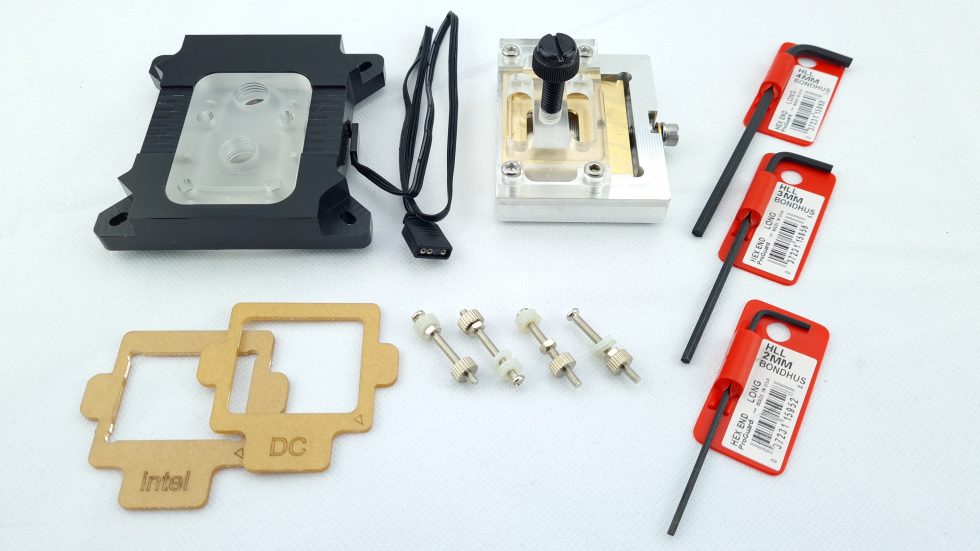

The packaging is just as spartan as the ordering process, but at least for this, in addition to the water block and delid tool, a set of Allen wrenches and templates for re-gluing the IHS are included.

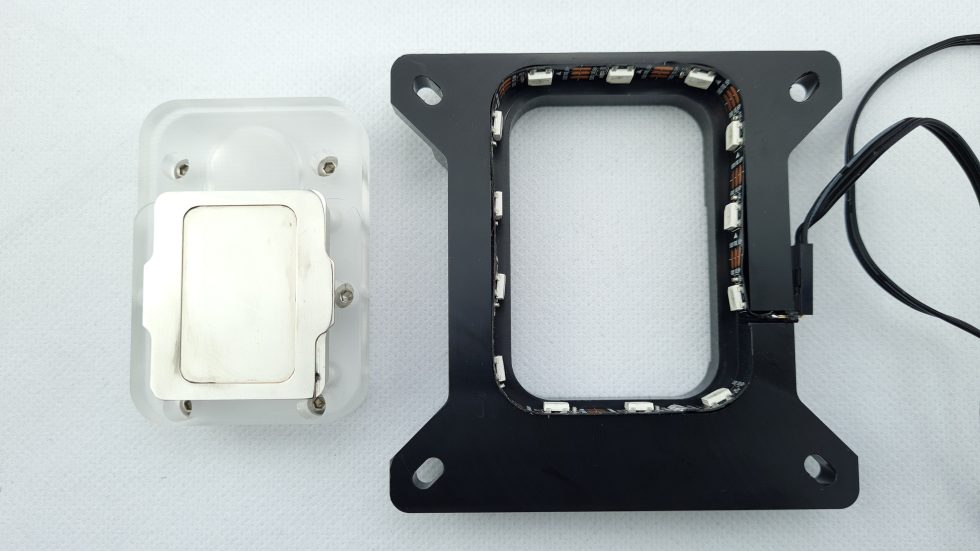

The water block itself consists of two components, the actual block with the water channels made of white, semi-transparent acrylic and a black frame with LGA1700 mounting holes and, of course, RGB lighting – how else could it be in 2022.

However, the latter is optional and does not have to be installed together with the actual cooler. If we turn the block over, the relatively simple construction of the frame with glued-in RGB LED tape is revealed, after all with the 3-pin digital standard.

The block can be easily removed from the bottom of the frame, so that the actual assembly is not further complicated. Here you can already see that the base plate of the cooler is effectively the shape of the Alder Lake IHS (Integrated Heat Spreader).

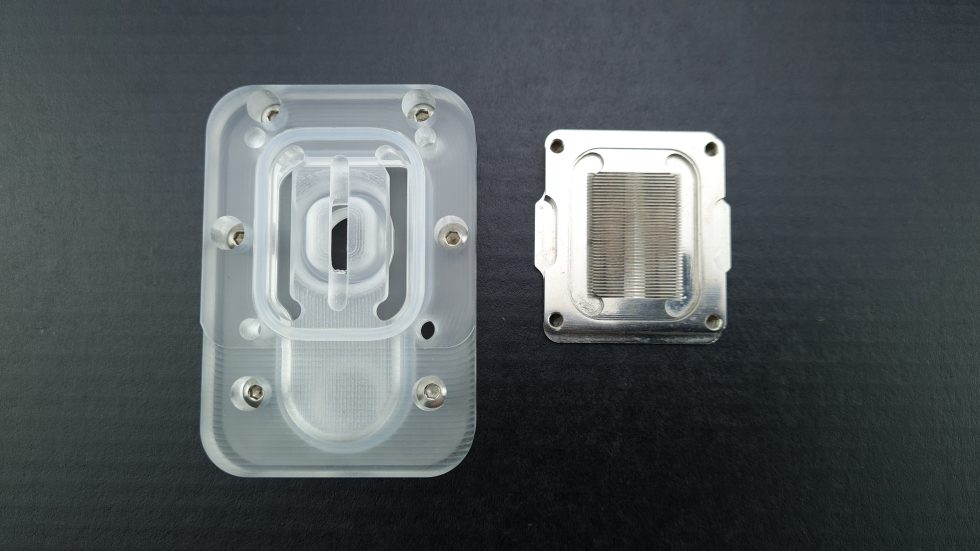

I’ll switch to a black background for the other photos of the block, so that the inner workings can be seen better. The block alone is hardly bigger than an LGA1700 socket and very plain. Besides the G1/4 inch inlet and outlet, there are only 4 recesses here for the screws to connect to the base plate. Furthermore, the lock-shaped inner workings can already be seen from above.

This is attached to the white acrylic element from above with four M3 screws with 2 mm Allen head and must be disassembled for later mounting to the CPU. Sealing between the components is provided by a semi-transparent O-ring, also white, which Supercool Computers says has particularly high flexibility and sealing capability.

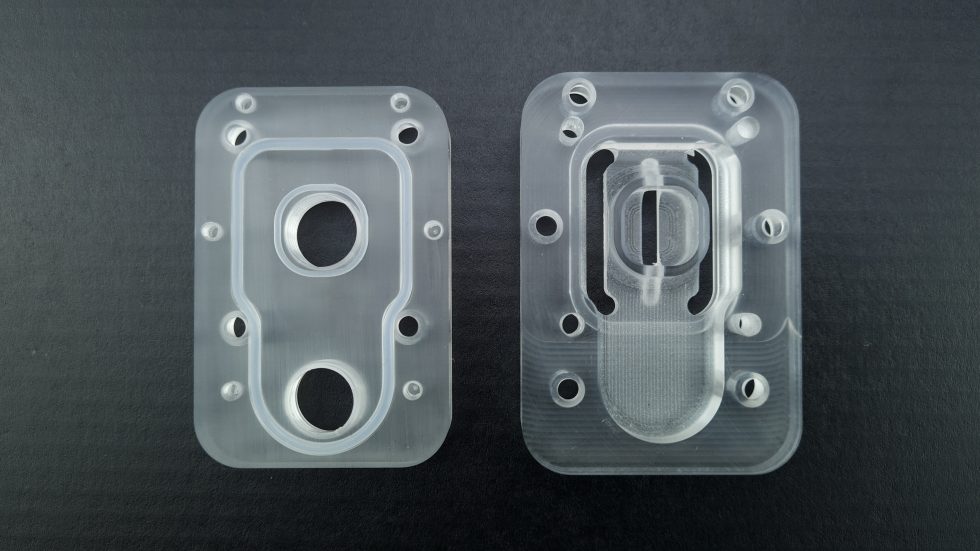

Again, six more of these M3 screws connect the two acrylic components, one effectively providing only the two G1/4 threads, and the other providing guidance of the water jet through an effective jetplate to the base plate and further guidance within the block. This time, two of the semi-transparent O-rings are used for the seal, a small one to separate inlet from outlet and a larger one to seal the block in general.

56 Antworten

Kommentar

Lade neue Kommentare

Mitglied

Urgestein

Veteran

1

Urgestein

Veteran

Mitglied

Mitglied

1

Veteran

Moderator

Urgestein

Mitglied

Veteran

Urgestein

Veteran

Urgestein

Urgestein

Urgestein

Alle Kommentare lesen unter igor´sLAB Community →