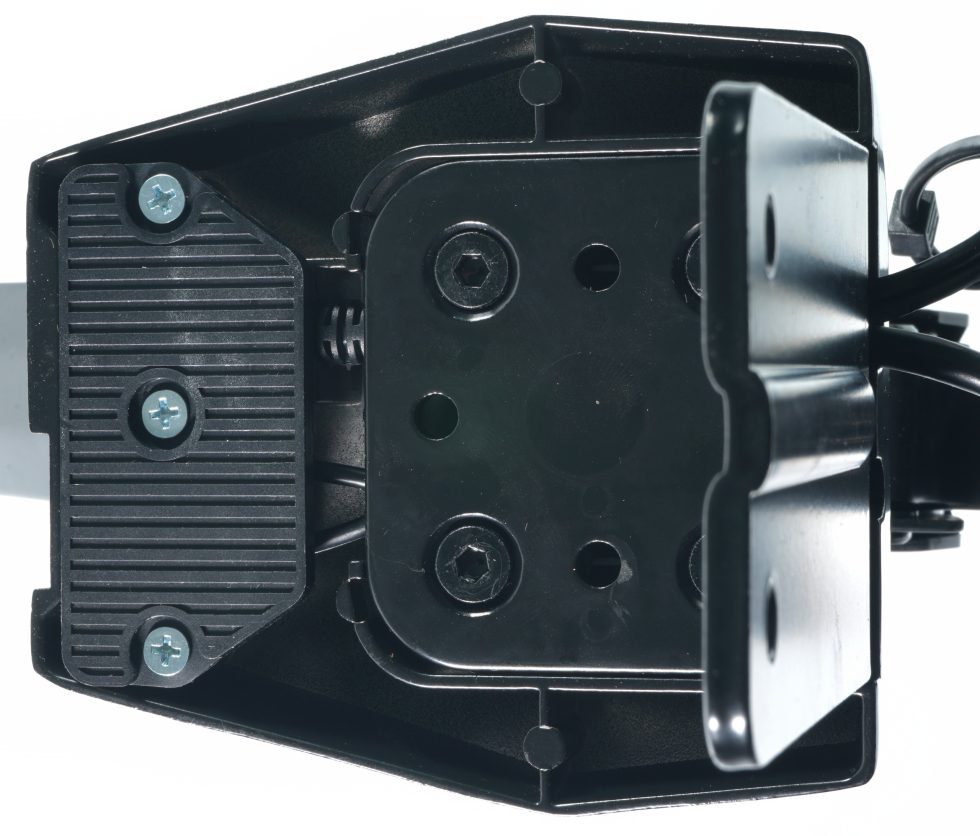

Now let’s move on to the assembly. The qualified screwdriver crew either uses the supplied Allen key or a set of proper bits together with the screwdriver. It goes both ways, of course. And so the massive angle of the table mount first finds its way to the base of the monitor arm. The powder coating is thick and durable, plus point. However, this is precisely why you have to check the threaded holes to make sure that no residue has settled in the beginnings. This makes screwing in much easier if you scrape it off beforehand.

After about 5 minutes, the four screws are countersunk and properly seated. However, since you can’t just put this on the table without leaving deeper traces of devastation….

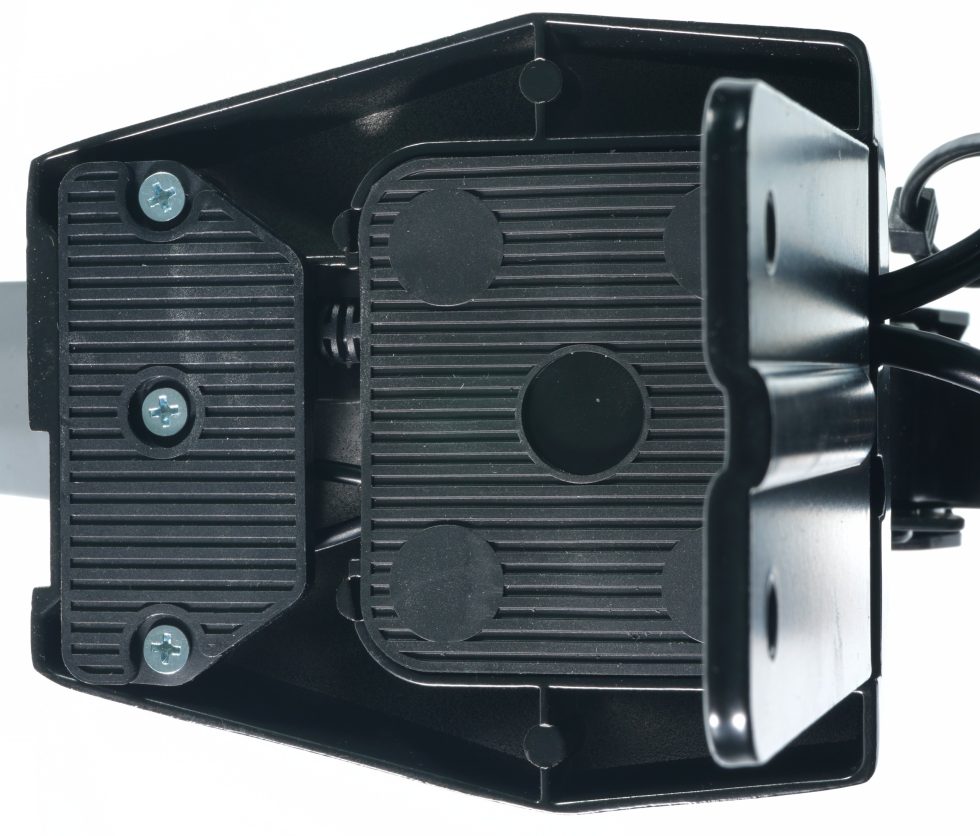

… there are the nice rubber pads, which can be easily attached by means of four knobs. I also did a pressure and abrasion test here on a piece of white film. This is not a long-term statement (keyword: plasticizer migration), but nothing stains there for a start. The rest of the contact surface is already rubberized ex works.

… there are the nice rubber pads, which can be easily attached by means of four knobs. I also did a pressure and abrasion test here on a piece of white film. This is not a long-term statement (keyword: plasticizer migration), but nothing stains there for a start. The rest of the contact surface is already rubberized ex works.

The two screws for the tensioner are quickly done and here, too, the first thing to look at is the free threads. Then you should measure the thickness of the tabletop and screw in the really extremely long screw until the distance between the rubber and the holding surface is approximately the same and the monitor arm can be attached to the table reasonably firmly. This makes it much easier to tighten the screws if, like me, you have full or massive tables where it is difficult to reach the screws. The clock does not show 10 minutes from the start.

An important remark I must insert at this point, because otherwise one falls fast on it: all joints are set by a RIGHT turn of the respective screws harder or more firmly, only the gas pressure spring requires a LEFT turn! I therefore recommend turning the screw all the way to the left stop even before mounting, because even if the monitor only weighs 5 to 6 kilos, you should leave it as tight as possible. It will give a little later anyway. This costs about 2 minutes.

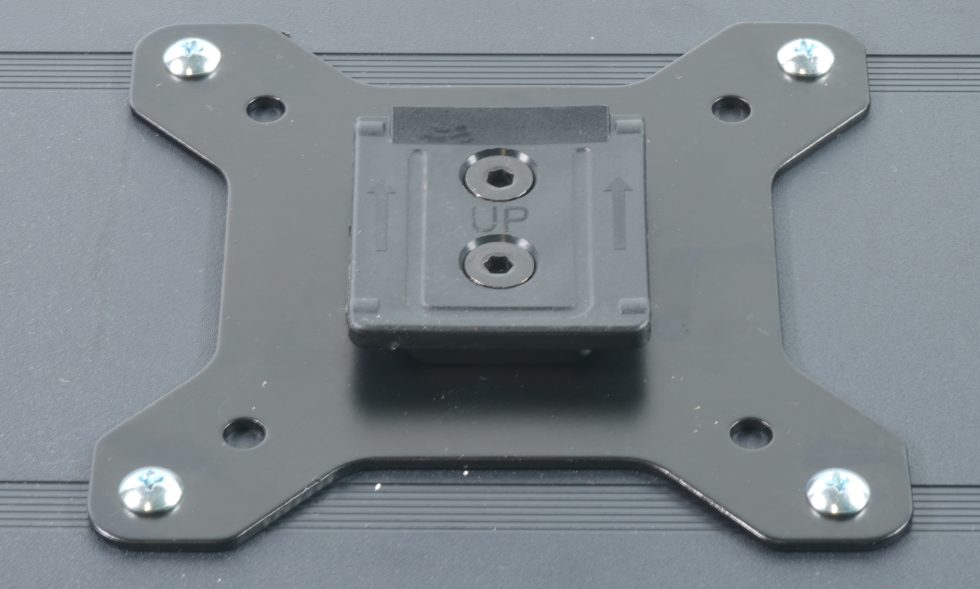

The pickup for the VESA mount has a lock via a spring leaf, so you already know that the VESA plate is directional when mounted on the monitor.

This is exactly what you can and must consider when screwing the VESA pickup to the monitor. There are two kits for this purpose. If the back of the monitor is flat and the four holes for the VESA mounting (75 or 100 mm grid) are not in a lowered area, take the short screws and screw the mounting plate directly onto the back. Again, it’s barely 5 minutes to the finished result, unless something doesn’t work out.

But beware! On my ultra-flat 32″ ViewSonsic, I reach the end of the receiving thread even before it is fully screwed down! If I would continue to turn here with force, I would end up with the screw on or already in the panel! However, the monitor’s design is also rarely stupid in terms of the VESA mount. But I wanted to mention it. I just shortened the screws a bit for my own safety. This is very easy to solve: screw on a suitable nut and simply nip off the interfering millimeters with a suitable pair of pliers. Then you just turn the nut down and the thread is nice again.

In addition, the second kit with the long screws is used here, which are also supported by the spacers. With the ViewSonic, you almost get the holding plate back to the level of the thickest part of the back panel. And always pay attention to the specified installation direction!

Once all this is assembled, you can screw the monitor arm to the table. I have here equal still used the XXXL pad with as a support: perfect!

The USB cable can now be connected to the PC without any problems, the two audio cables as well. When you think you need it.

29 Antworten

Kommentar

Lade neue Kommentare

Mitglied

Neuling

Veteran

1

1

Veteran

Mitglied

1

Veteran

1

Moderator

Mitglied

1

Mitglied

Mitglied

Veteran

Veteran

Mitglied

Alle Kommentare lesen unter igor´sLAB Community →