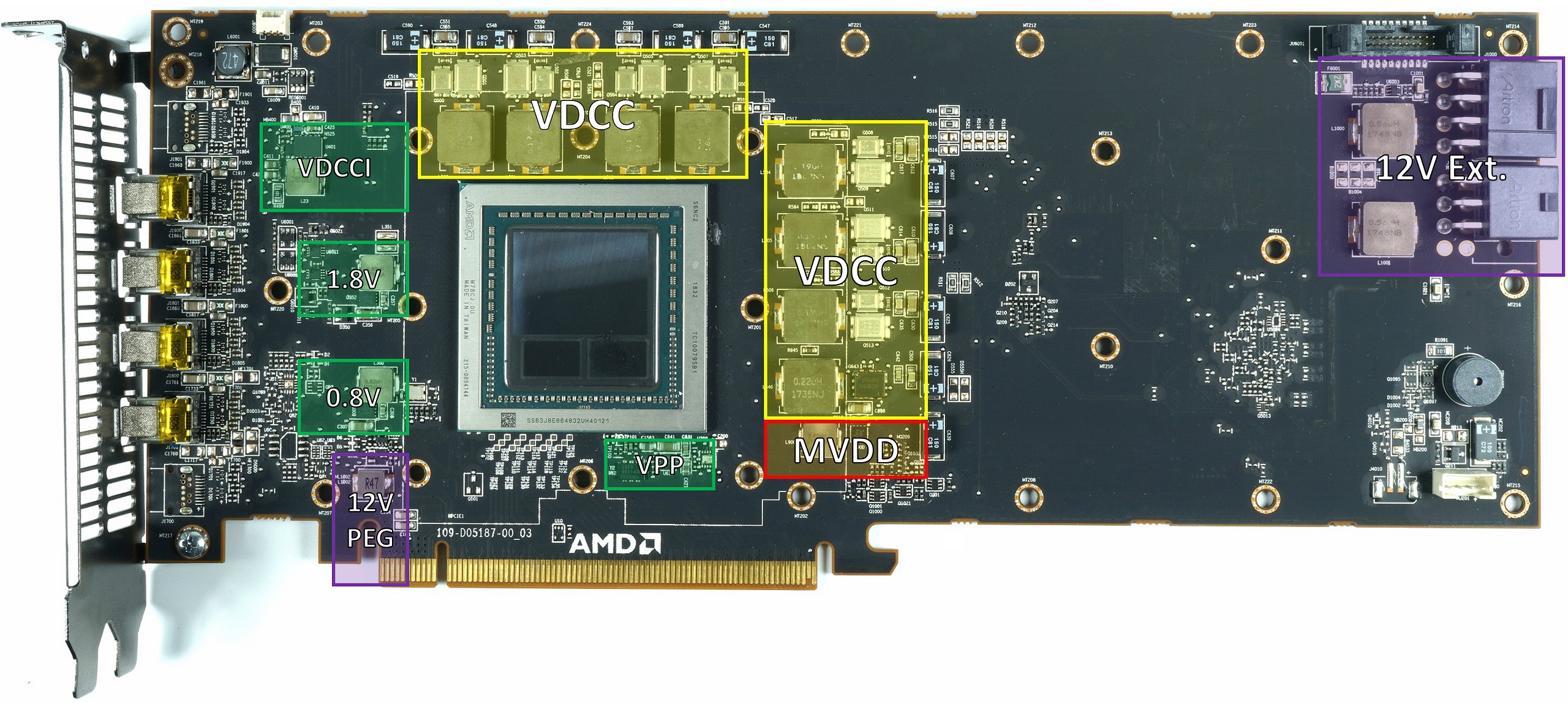

Board analysis and electrical components

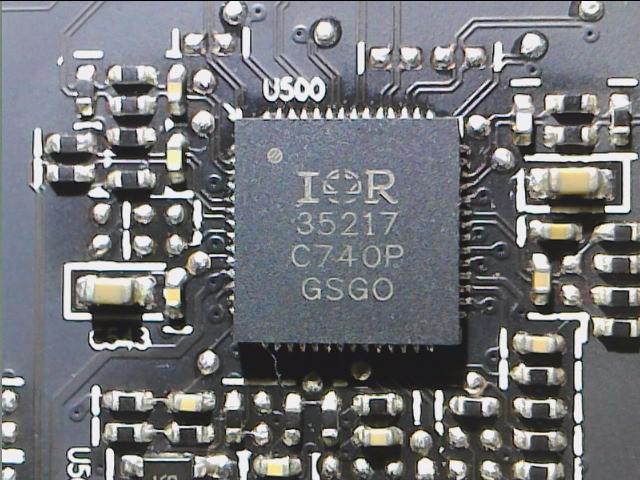

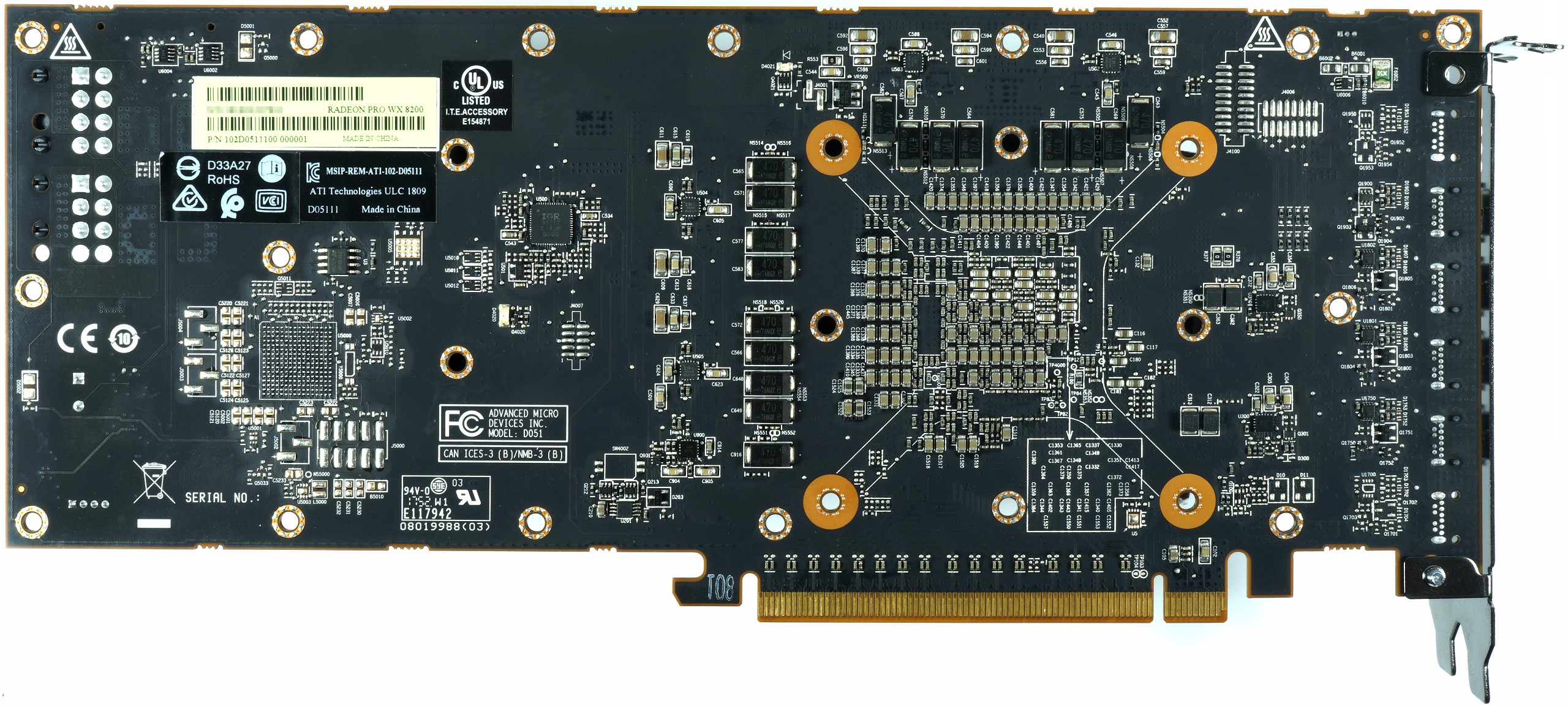

The circuit layout is a bit tricky, because the board deviates a little from that of the Vega56 consumer cards. At the heart of the GPU power supply, however, is the IR35217. This PWM chip is a dual-loop digital multi-phase buck controller and comes from International Rectifier. In the layout used here, AMD dispenses with doubler chips and works with a total of seven real phases for the GPU and one phase for memory.

The production of VDDCI is not a big item in terms of performance, but it is important. It is used for GPU-internal level transition between the GPU and memory signals, something like the voltage between the memory and the GPU core on the I/O bus. In addition, two constant sources for 1.8V and 0.8 volts are shown. Below the GPU you can also find the APL5620 from Anpec for the VPP. This ultra-low dropout chip generates the very low voltage for the Phase Locked Loop (PLL) range.

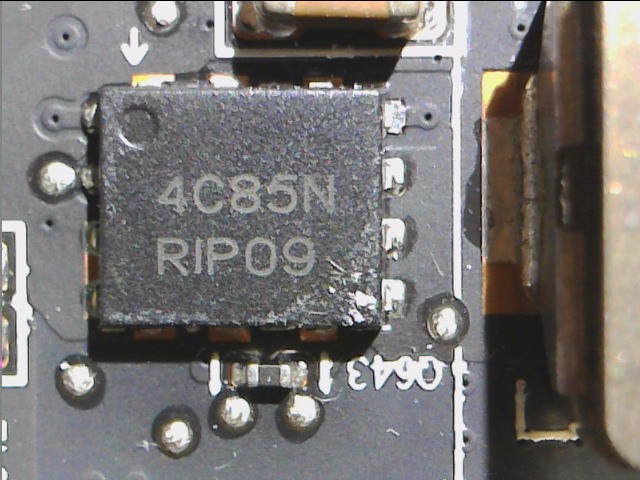

If the consumer cards with 6 double phases (12 voltage converters) came to the customer, there are 7 single phases (and thus only 7 voltage converters). Instead of the doubler chips, AMD uses the ADUM5230, an Isolated Half-Bridge Driver with a special high-side output to control the 7 single phases for the GPU and one for memory. These 4 chips are located on the back of the board near the VRM. Each of these chips can operate two phases independently and separately.

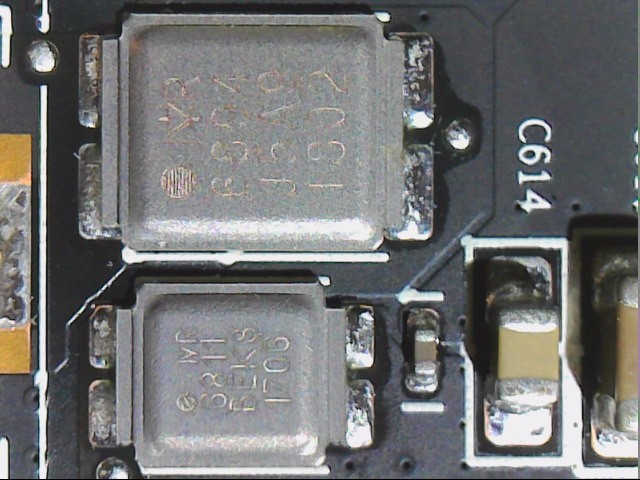

The actual voltage conversion of each of the 7 converter circuits is performed by an IRF6811 on the high side and an IRF6894 on the low-side, which also contains the required Schottky diode. Both are previously USED by AMD HEXFETs from International Rectifier. In the case of coils, AMD relies on encapsulated and front-soldered ferrite core coils. The inductance is slightly lower at 190 nH than the usual 220 nH for THE GPUs.

As mentioned briefly, the IR35217 also provides one phase for storage. One phase is sufficient because the memory is much more adequate. The gate driver is half of one of the four ADUM5230s (while the other half is used for a GPU phase), while an NTMFD 4C85M from ON Semiconductor is used for voltage conversion. This dual N-Channel MOSFET realizes both the high and the low-side in one package.

The coil for the storage phase is slightly larger this time at 220 nH. At 820 nH, on the other hand, the coils for the significantly slower clocking converters of the other two partial voltages are even larger, which, however, also have to withstand significantly lower currents. It is also interesting that AMD generally dispenses with all cup capacitors and only relies on flat SMD caps. The slightly lower capacity can be compensated by simply switching two of these caps in parallel and usually also using the back of the board.

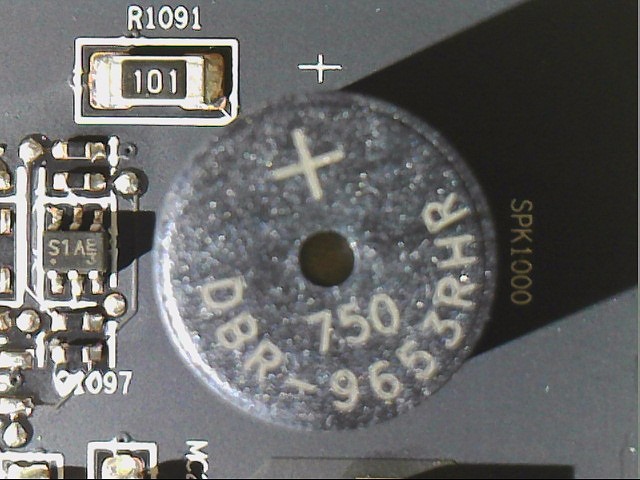

The card has a single BIOS, unfortunately you can't switch anything. So we will be watching with excitement what power consumption philosophy AMD is now closely following in this map. Until now, all workstation cards were lower clocked and therefore more efficient. In the event that the fan is farewelled or otherwise a disaster has occurred, the fixed beeps era is at least an acoustic warning option.

The respective inputs of the power supply are blocked with coils against peaks, but one should perhaps have provided a few capacitors. Thus, a more effective LC link becomes only a simple longitudinal choke. Whether it is enough, we will see in a while.

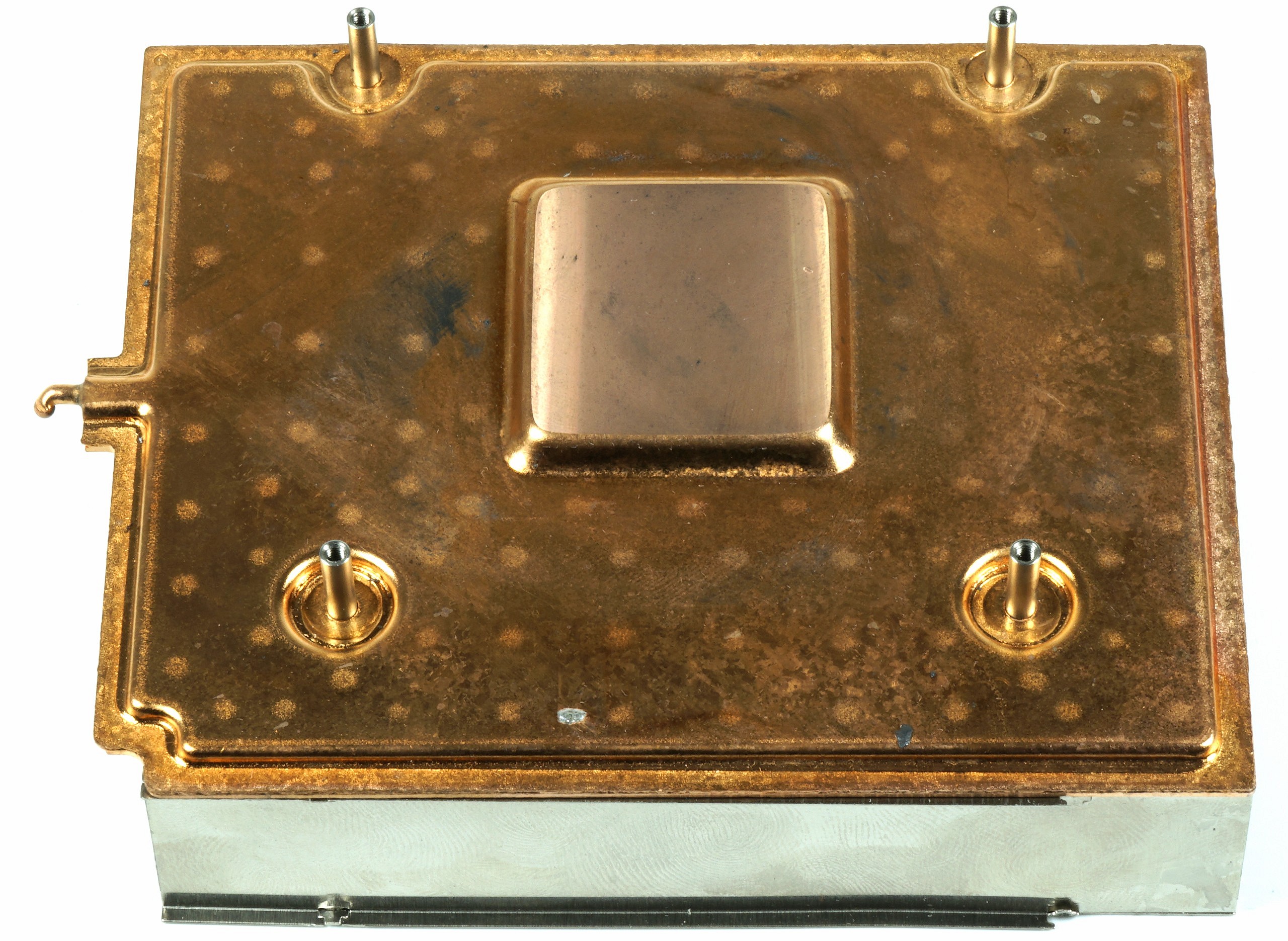

Coolers in detail

Removing the upper hee cover requires some suitable tools. With a small Torx screwdriver (T5), the six small swivels that hold this cover can be turned out. After that, the interior with the actual cooler and the large mounting or Cooling frame free.

AMD is again relying on the Direct Heat Exhaust (DHE) principle for this card, which does not have to be a disadvantage. We see the radial fan in the suction chamber and the path of the air, longitudinally through the block of the chamber cooler up to the slot panel. On the top of the board sits the massive mounting or Cooling frame, which on the one hand holds the entire structure together and on the other hand also represents an important cooling element.

The design has learned, because similar to the first gigabyte (Aorus) on the GTX 1080 Ti Xtreme Edition, one also relies on relatively well heat-conducting coil housings, which are also cooled by thermal lyre pads, similar to the VRM of the voltage converters. even the appropriate recesses in the frame. We will see later that this works.

With the 7cm radial fan, AMD relies on a single ball-bearing model from Delta and not one of the snarling and far too loud examples of the reference predecessor models. Compared to the previously up to 10,000 rpm, the extra-strong fan of the BVB1012 series only rotates up to a maximum of 6,000 rpm. AMD sets the fan target to approx. 32% to 33%, which is then equivalent to about 2,000 rpm.

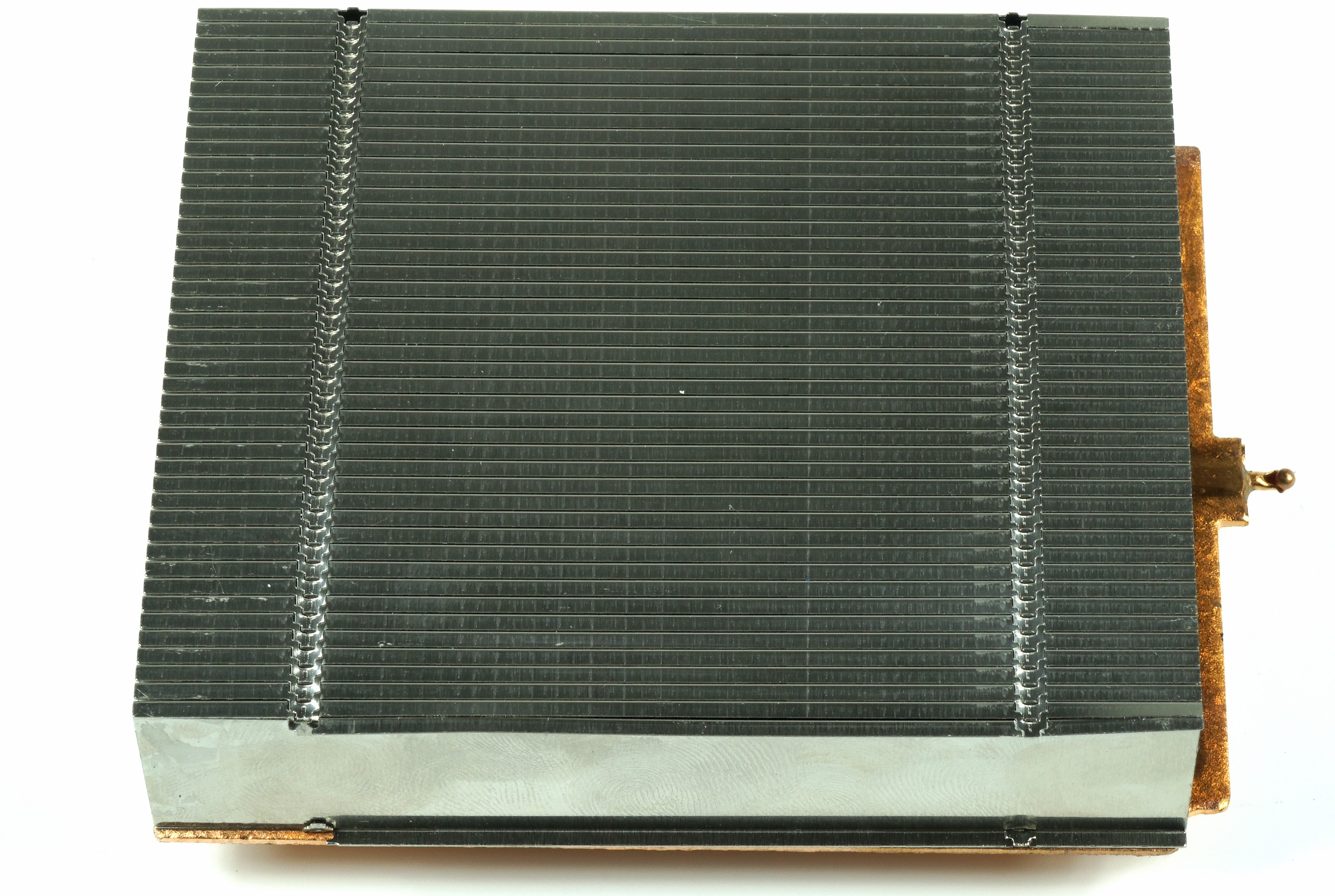

The actual chamber heat sink as a thin aluminium fin sits on a large vapor chamber made of copper. One sees the soldered outlet of the one-piece hybrid vapor-chamber (One Piece), which one must not bend down. The moulded heat sink is adapted to the package in size

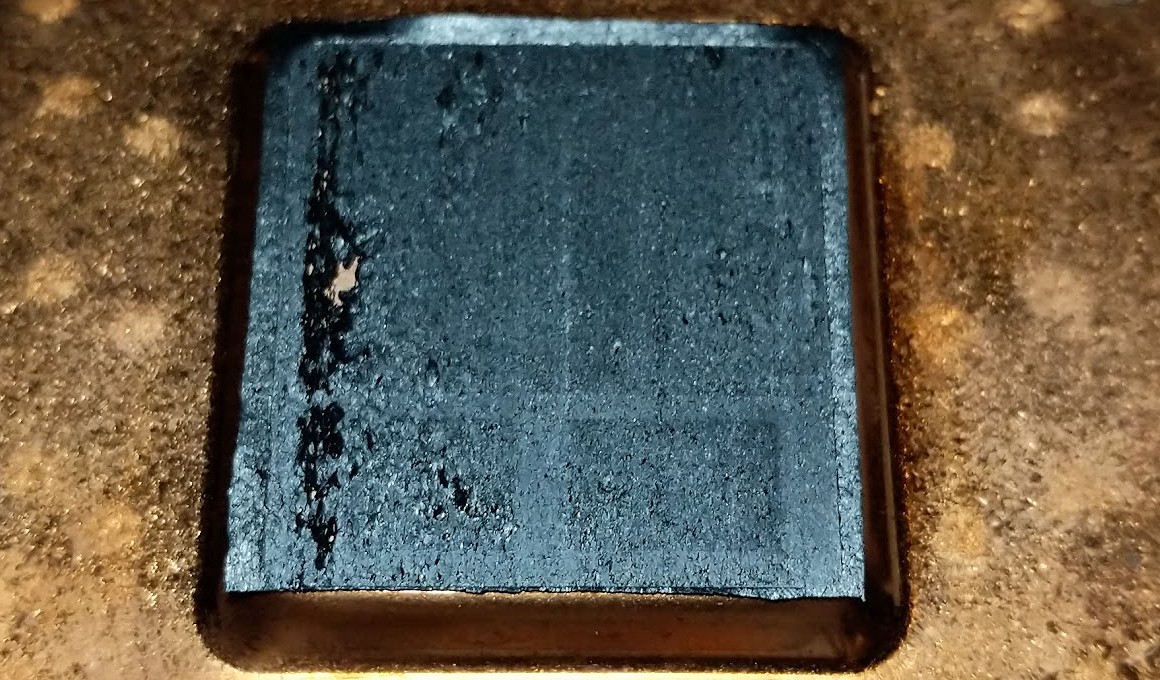

Thermal conductive coal instead of paste?

If you want to take the card apart or need to, you should be really careful! Because what AMD sticks between Heatsink and GPU really has it in it! Instead of the usual paste, one encounters an almost bitumen-like, almost black covering. What has been applied is pure graphite paste! This is extremely rare and certainly not quite uncomplicated in handling, as we will see in a while.

The layer is relatively thick and it is not easy to remove it cleanly. You only get the whole thing solved in the really hot state and who tries it cold but still has a very big chance to crack the interposer. The thermal conductivity of graphite pastes is undisputed, but they also have a very specific disadvantage.

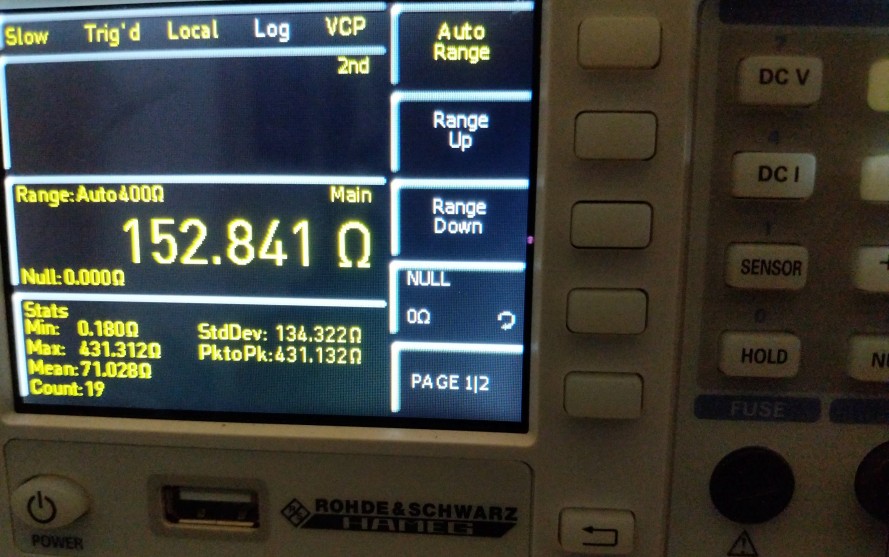

Unfortunately, the stuff is electrically quite good conductive! At a distance of approx. 2.5 cm between two measuring points I measure, the touch tips only loosely applied, already around 150 ohms, which should be even less if one presses significantly more firmly. I used up my last remnants of graphite paste (fisherman) to restore the card to its original state. An interim attempt with IC Cooling Diamond yielded similar results, but that is guaranteed to be too expensive for AMD. Then i'd rather graphite, which is cheaper.

| Cooling system at a glance | |

|---|---|

| Type of cooler: | Air |

| Heatsink: | Copper, graphite thermal paste |

| Cooling fins: | Aluminum, horizontal alignment Chamber |

| Heatpipes | None, Vapor-Chamber |

| VRM cooling: | GPU VRM via mounting and cooling frame |

| RAM cooling | GPU Heatsink |

| Fan: | Radial fan, no fan stop |

| Backplate | No |

Kommentieren