The 12VHPWR adapter for the GeForce RTX 4090 is unfortunately already a kind of running gag and so the topic is meanwhile beaten by all more or less well-informed media. A little unemotional reappraisal would certainly not be a bad idea to calm heated tempers and put the whole thing back on its feet. Therefore, today’s article is not only an inventory, but I have also compiled some technical facts and documents that reflect well the complexity of the problem.

It would also be wrong to make the user the sole culprit, even if the human factor plays a very large role here. The person with a defective connector doesn’t even have to feel guilty, because it’s still the industry’s job to produce such things in a user-safe manner. But let’s always stay in order, because I have some new findings that really need to be presented chronologically. The fact that the consequences of poor connectors ultimately spring from a long causal chain doesn’t make it any easier either.

At this point, my thanks go of course as always to my sources from the R&D of various graphics card board partners (AIC), which I will of course not mention by name at this point, to Christian Rex from be quiet! for all the cables and insights, and of course to Gabriele Gorla (Director of Engineering at NVIDIA), with whom I had a longer conversation yesterday. The latter also explained to me very credibly how seriously NVIDIA takes the problem and why he is in Taipei at the moment. Of course, you have to listen to all sides and finally weigh the arguments well against each other, because many things are absolutely the same, just from different angles.

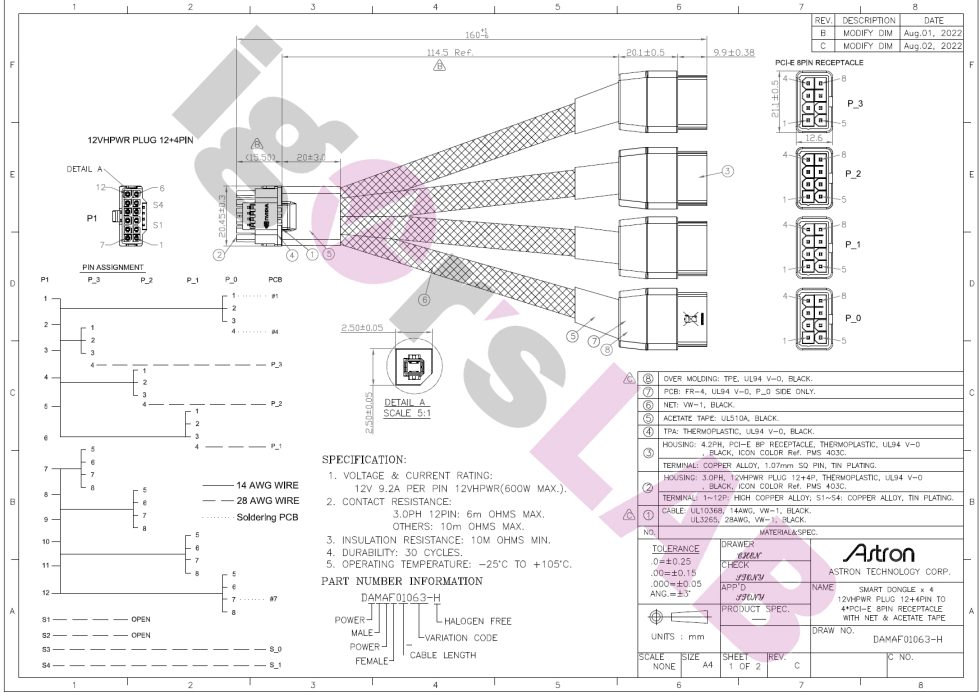

The x4 adapter from Astron – theory and practice

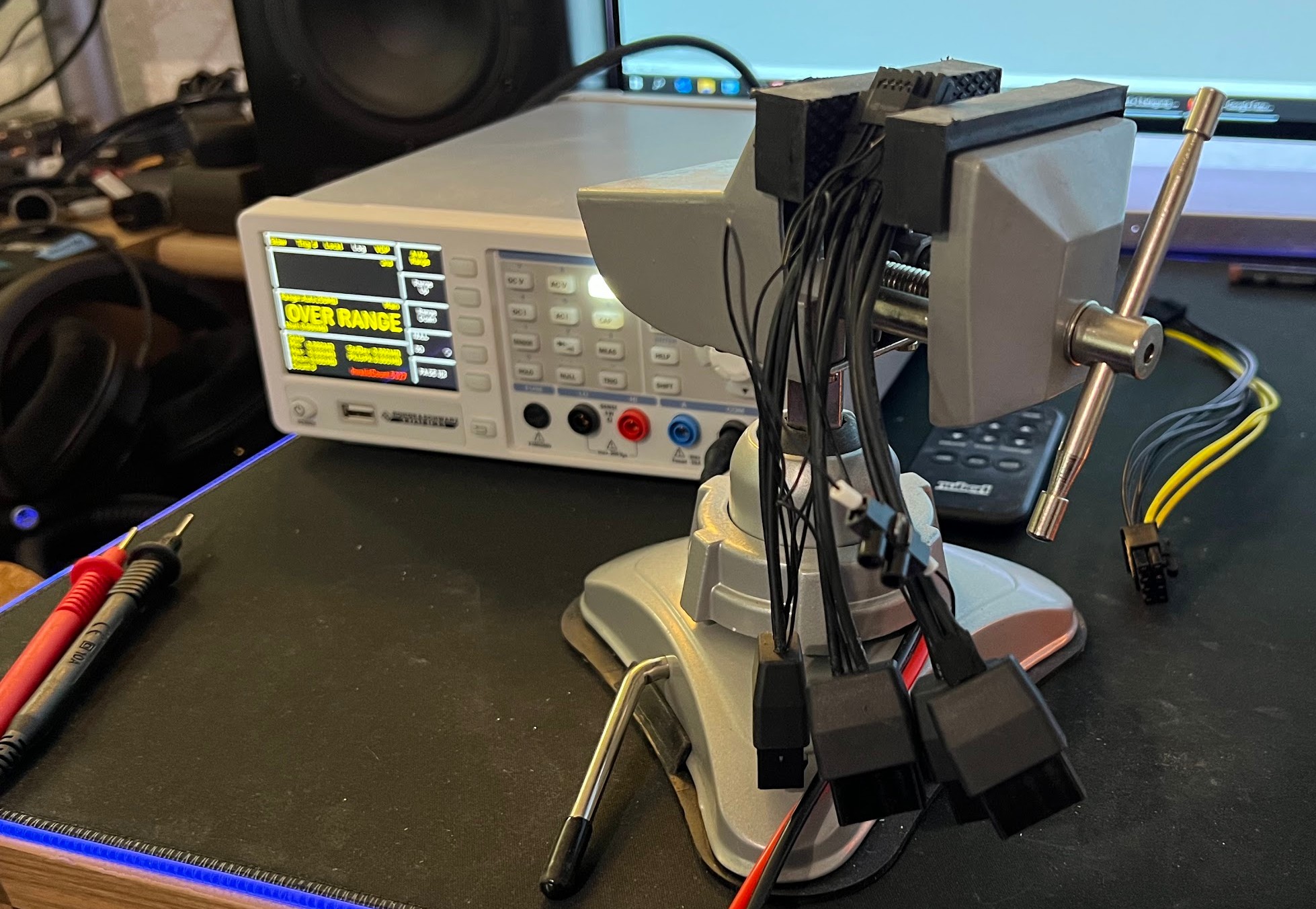

Since Astron is the leading manufacturer of the adapter (x4 and x3), I have “obtained” the construction plans for this adapter as an introduction. I am presenting the important schematic overview here as an example, because it also shows that some of the deficiencies identified so far should not have occurred at all.

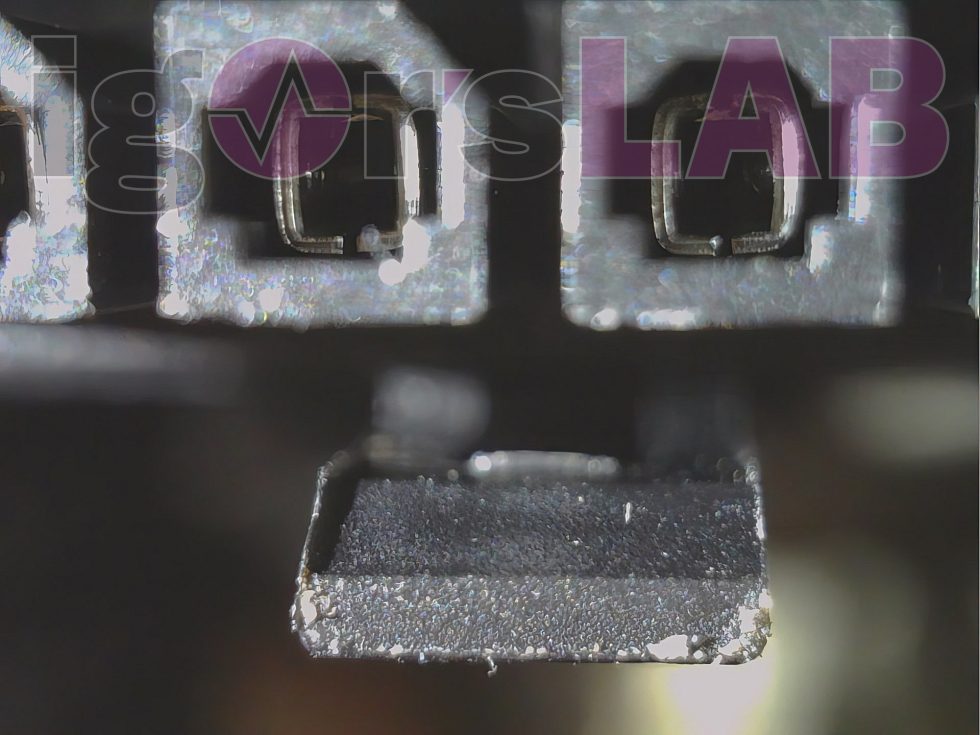

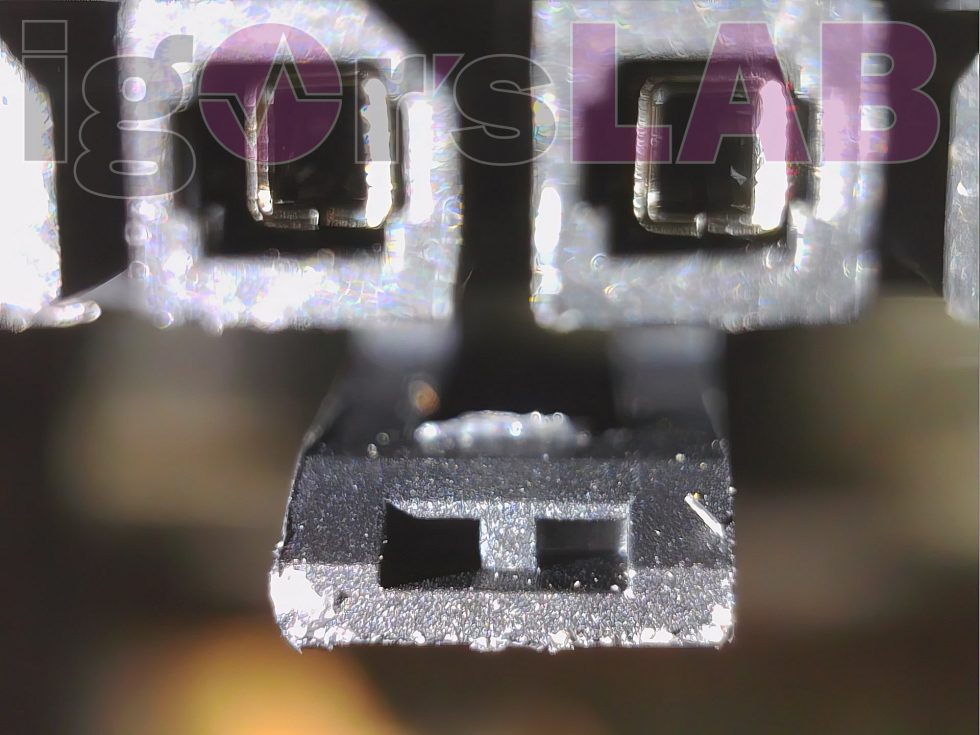

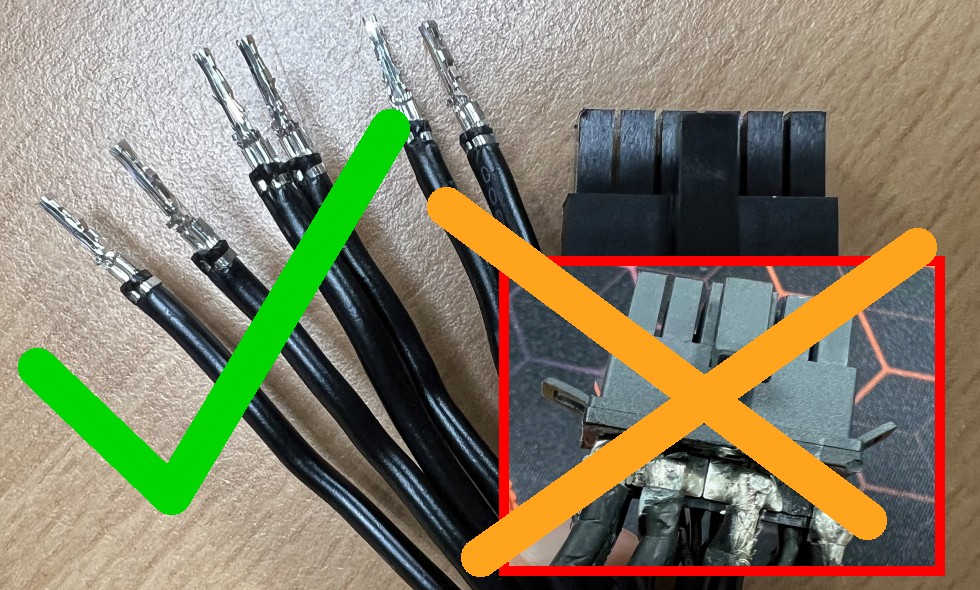

I had reported about the cut open connector, whose solder joints on the pads turned out to be quite critical, especially since the solder quality also contradicted all standards (picture below). In addition, the attachment of the cables to the solder pads of the contacts contradicts the specification from the drawing (picture above). In this (and a few other) cases, one must assume a production error that can ultimately probably be reduced to a single worker who positioned the feeders incorrectly out of ignorance. This then also explains the rarity of this error, which, however, could have been avoided through proper training and the obligatory quality control.

The fact that such a strong 14AWG stranded wire with a nominal cross-section of over 2 mm² is rigidly soldered onto such delicate solder pads without providing adequate strain relief is, in my opinion, a serious design flaw. Whether something like this is even permissible or marketable in Germany or the EU in this form, I leave to the judgment of third parties at this point, because it is a possible breaking point, but not the cause of thermal deformation and fused plugs. What you can’t see in the drawing, however, are the spring contacts used in the connector. I’ll have more insights on this topic in a moment, and it leads me to another player, because some of the board partners’ boxes also contain adapters from another manufacturer.

The x4 adapter from NTK

NTK is also a Taiwanese company and quasi also a direct competitor of Astron. Since I could meanwhile collect various adapters and also some from R&D of the board partners, knowing that they are doing their own comparison measurements of different adapters, I was also sensitized enough to recognize the different origin of the adapters with the naked eye. Both carry the NVIDIA logo and also look completely the same at first glance. Well, at least almost. Because there are two more or less serious differences here.

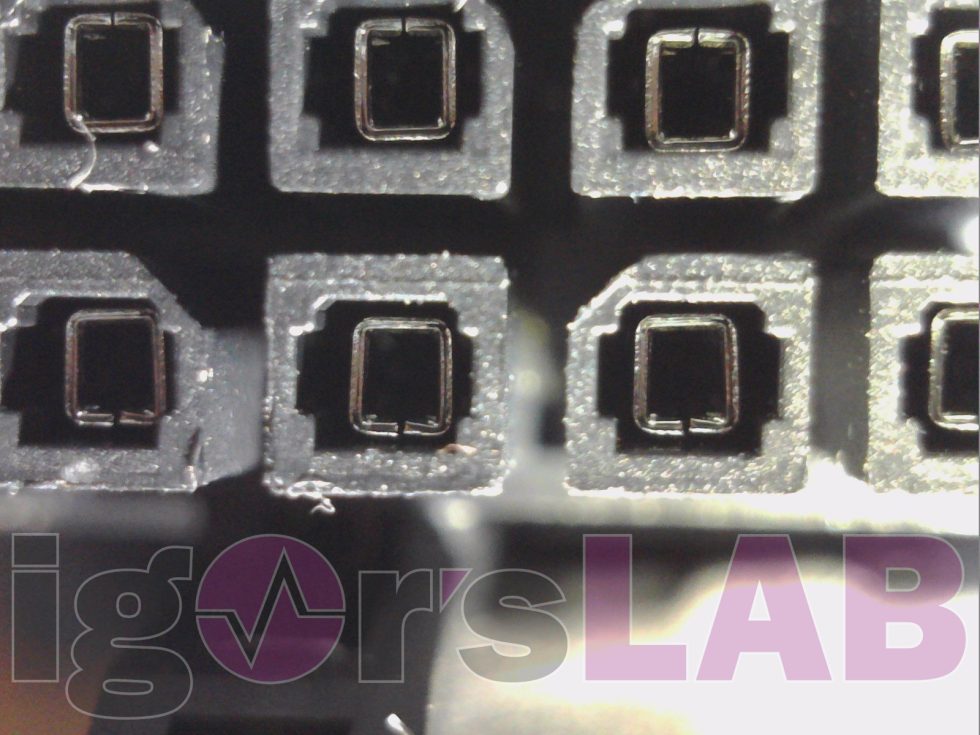

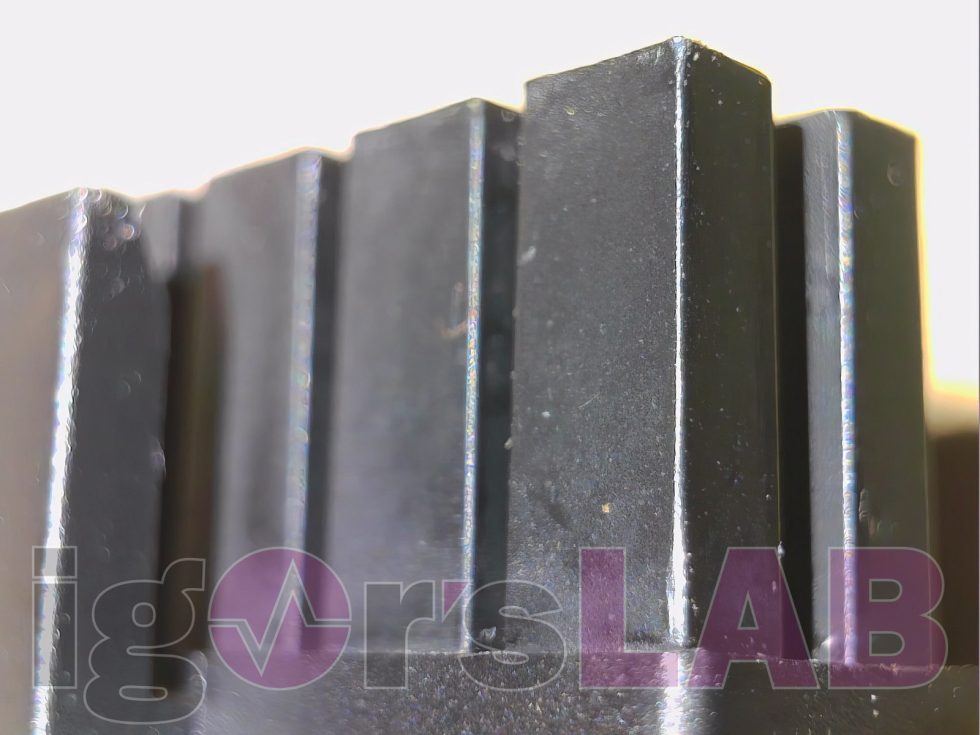

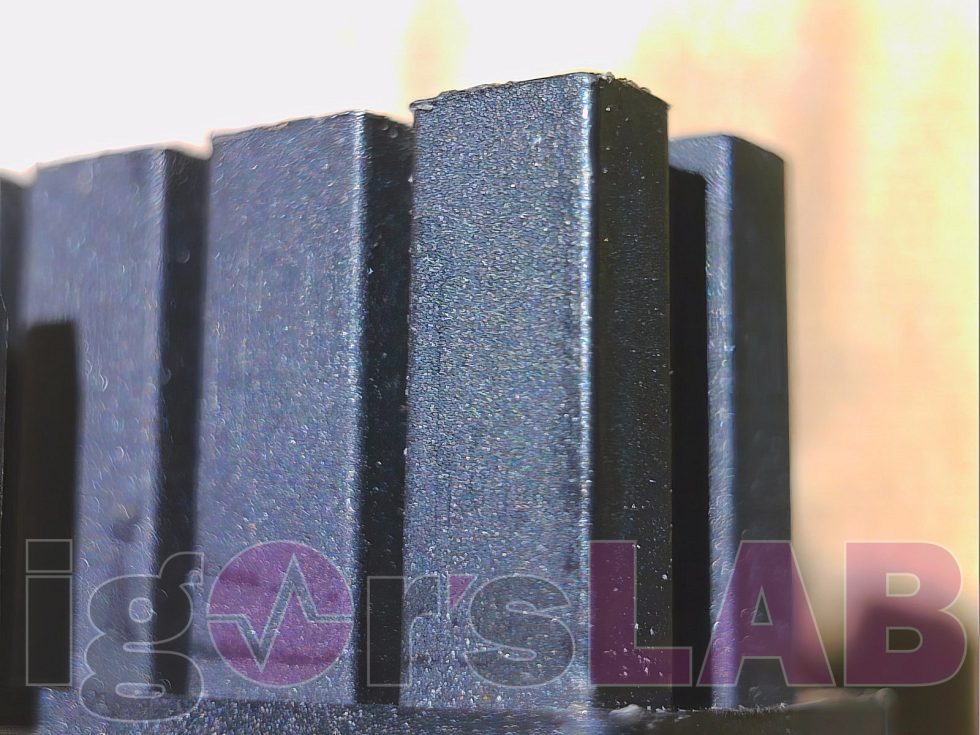

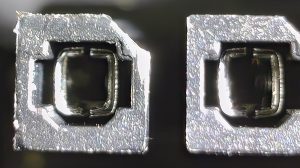

The first difference is the nose of the lock. Purely subjectively tested and after the blind tests with third parties, the plug from NTK latches better. Both in terms of the tactile feel and the slight acoustic clicking noise. It is also easier to detach, which definitely increases usability and operational reliability. But I’ll get to the problem of inserting it correctly. The second difference is in the spring contacts used. Astron uses spring contacts with two slots, NTK only one.

The material used in the injection molding also seems to differ somewhat, probably Nylon 66 (PA66) was specified for both connectors. The plug from NTK seems a bit coarser on the surface and you can also see more “grinding marks” after plugging, but this is not disturbing. Unfortunately, I can’t quickly find out why this is the case in detail and whether manufacturing tolerances still play a role in the casting.

As far as I know, some cards from Zotac (PC Partner) were initially equipped with NTK adapters. Furthermore, other partners like Gigabyte have also conducted their own tests on these NTK adapters and have at least certified a lower contact resistance (especially when plugged in several times). Yesterday, Gabriele Gorla had also shown me measurement data from Astron in this regard, which certified that the Astron plug was still less than 1.5 mOhm over the complete load bandwidth even after being plugged in 10 times. This is somewhat at odds with a boardmate’s findings that NTK contacts have higher durability and lower resistance, but since I can neither prove nor disprove either, I’ll leave it at a mention.

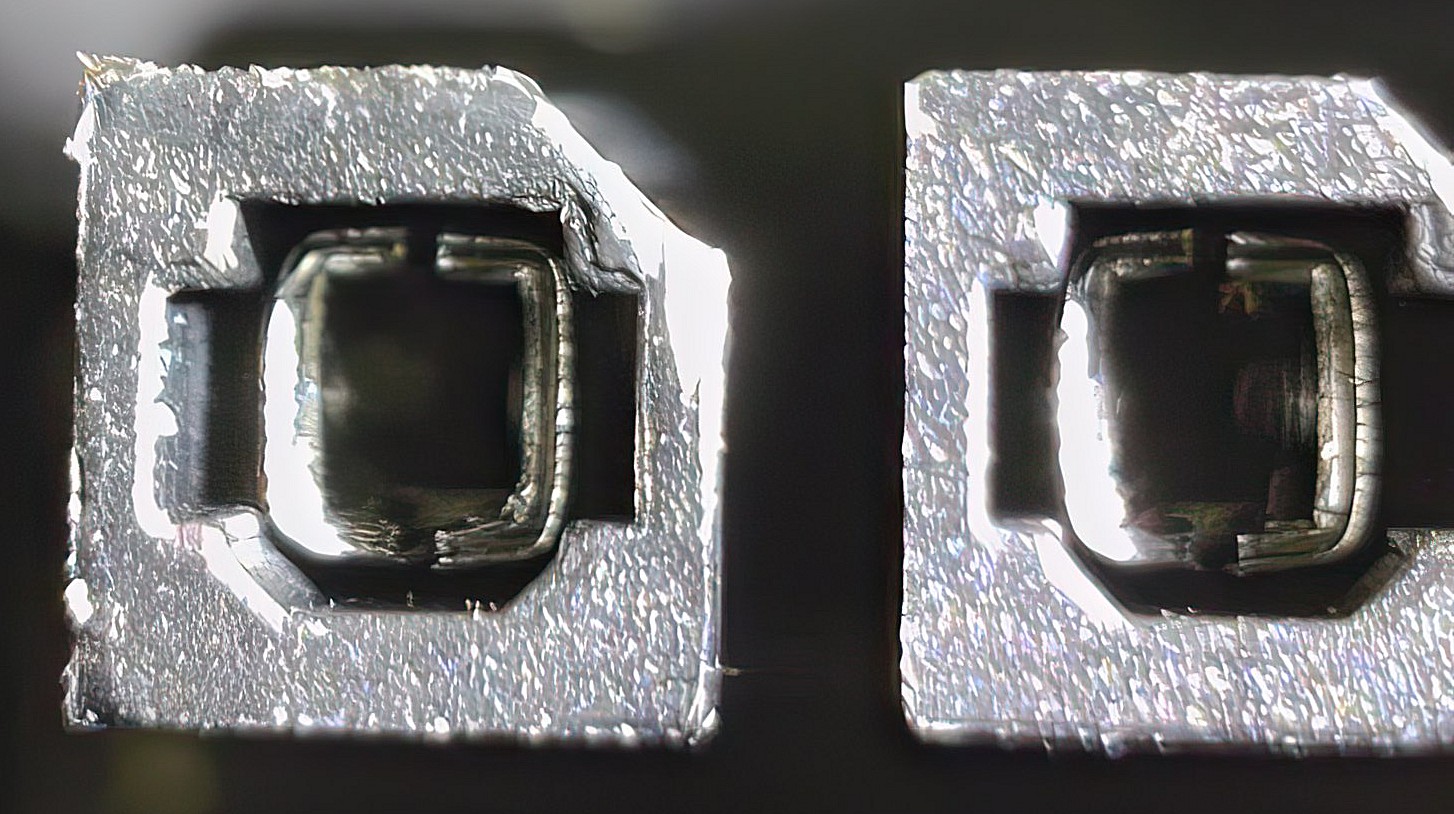

To understand the problem of spring contacts, you also have to deal with the basics. Astron’s double-slotted contact follows the so-called “tulip” design, where contacts on one side spring-close around a center contact on the opposite side. Since this can be most easily compared to the shape of a tulip, this system also bears this significant name. Incidentally, with the Astron connector, only one of the two slots is continuous almost to the end of the contact path, the second is slightly shorter to prevent it from breaking open. The “finger and wedge” contacts or butt (“butt”) contacts play less of a role here.

NTK’s contact is also still a “Tulip” design in the broadest sense, but they have intentionally limited themselves to a single continuous slot here. This significantly increases durability and stability, but possibly also restricts the ease of insertion somewhat. The plug from NTK generally requires a slightly higher press-in force, but I personally do not find this particularly annoying, because there are many other factors such as the remnants of the injection molding on the plug, which can hinder the plugging process much more concisely.

I have for you an exclusive foil from NVIDIA to show you the difference between both contacts, enjoy!

CEM5 Connector - Plug comparisonWhich brings us de facto to plugging in, which I also have to say a few words about this (and yes, we’ve done that before, even with a video). More about this on the next page.

Further articles and basics

321 Antworten

Kommentar

Lade neue Kommentare

Veteran

1

Urgestein

Urgestein

Urgestein

Veteran

Veteran

Urgestein

Mitglied

Mitglied

Veteran

Veteran

Veteran

Veteran

Veteran

Urgestein

Veteran

Veteran

Urgestein

Alle Kommentare lesen unter igor´sLAB Community →