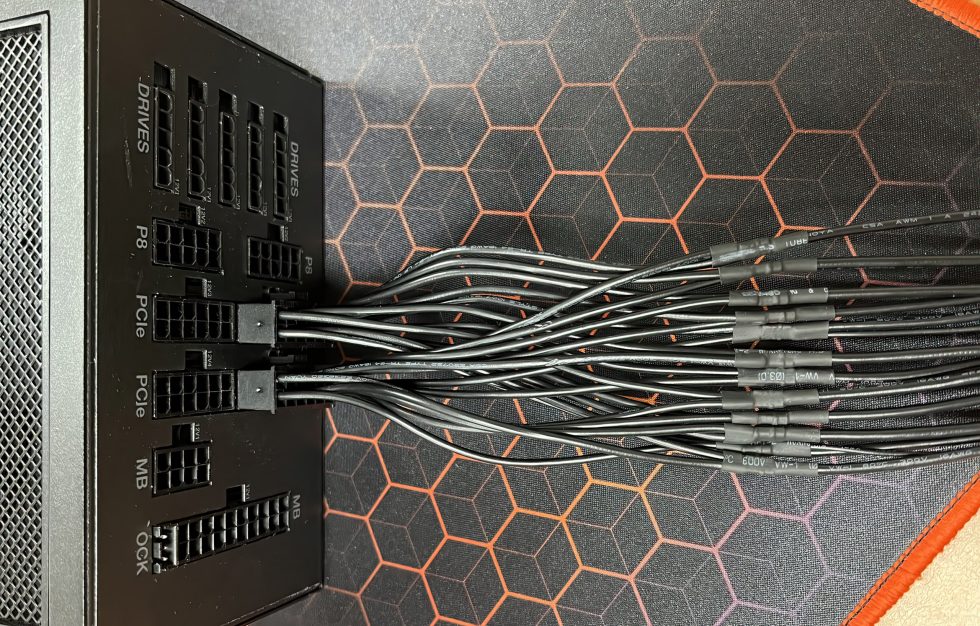

First there were bent cables, then annoyed buyers of the at least 2000 euro expensive NVIDIA GeForce RTX 4090, no matter which model or manufacturer. The manufacturer of the 4-pin adapter from 12VHPWR to 4x 8-pin for older power supplies was also careless. And, of course, we learned something once again in the course of our investigations. Since I’m using my brand new cables for the not-yet-released Dark Power Pro 13 from be quiet! i didn’t want to destroy them as well, so I’ll show you what the inner workings of the Dark Power Pro 12 cable look like and what you should still pay attention to, based on the frequently requested 12VHPWR cables.

Let’s see today’s article simply as a practical test of how to do it better and right as a manufacturer AND user. The cable from be quiet! is of course representative for all other cables tested here, e.g. from Corsair. Unfortunately, my resources are also limited and the market is virtually empty. Therefore, today I take as an example the cable, of which I own several copies and can thus also easily get over the total loss due to the special operation for demystification.

As a reminder, you can see the sad caricature of an adapter above, which would make legions of electrical engineers jump out of the window in shame and anger. And what has been done wrong with the adapter with the sad figure? The fact is that this soldered manual work of art disregards several factors at once, which has already been confirmed to me by some of those involved:

- Rigidly tinning and soldering stranded wire that is sensitive to tension and bending without relief is against every rule.

- Processing stranded wire in this way can also cause the stranded wire to unravel and break individual wires.

- The contact resistance also increases sharply in the present design.

- The thermal load on the pad during soldering is already too high. The pad becomes soft and brittle and then falls off under mechanical stress (picture above, right pin).

- Extreme quality fluctuation due to manual work (no wave solder bath with preheating and defined solder temperature or quantity, no quality control except visual inspection)

- The lack of neatly crimped connections instead of manual soldering of such massive and rigid 14AWG cable bombers (plenty of 2 mm² nominal cross section) is not excusable

1. Crimping instead of soldering!

Of course, as an outsider you can always complain, because it doesn’t make any work. That’s why I’m now going to show you an example of how a manufacturer should and must do it right. I’m happy to sacrifice my cable if it helps the public in some way. (I’m already getting one again, there will be quiet! certainly not let beg three times 😀 ). My Dark Power Pro 12 of the test system still has the current accessory cable hanging from it, which connects the 12VHPWR to the two 12-pin Molex sockets of the power supply. The sleeve can be carefully cut open and removed…

The wiring harness is highly interesting, as both plugs have six 12-volt and six ground wires each with very flexible 18AWG cables (0.82 mm² nominal cross-section), which are also easy to route and bend. These 24 wires (2x 12) then terminate in a total of 12 thick 16AWG wires with a nominal cross-section of around 1.52 mm². According to PCI SIG, this is also quite sufficient. The combination of two thin wires into one thick wire is done by crimping the ends of the wires.

Normal 16AWG cables usually consist of 19 individual wires, the stranded wire used by be quiet even consists of 65 wires with a diameter of only 0.16 mm. And how do you calculate the resulting nominal cross-section? This will now be highly interesting, because 16AWG is not always equal to 16AWG! If you take the square of the diameter, divide that by 4 and multiply it by pi, you have 0.0201 mm² per wire. This then times the number of 65 wires gives about 1.31 mm² net cross-section. Since the wires are round and there is also air in between, the measurement results in a nominal cross-section of about 1.5 to 1.52 mm².

If you take a single cable with a length of 60 cm and a full 13 amperes, it will be at most hand-warm (<= 40 degrees after one hour). That is the mental upper limit for me, because we are already at 936 watts in the sum of all lines, if you convert it to power. The pin in the connector is then at around 50 degrees, but it is only one.

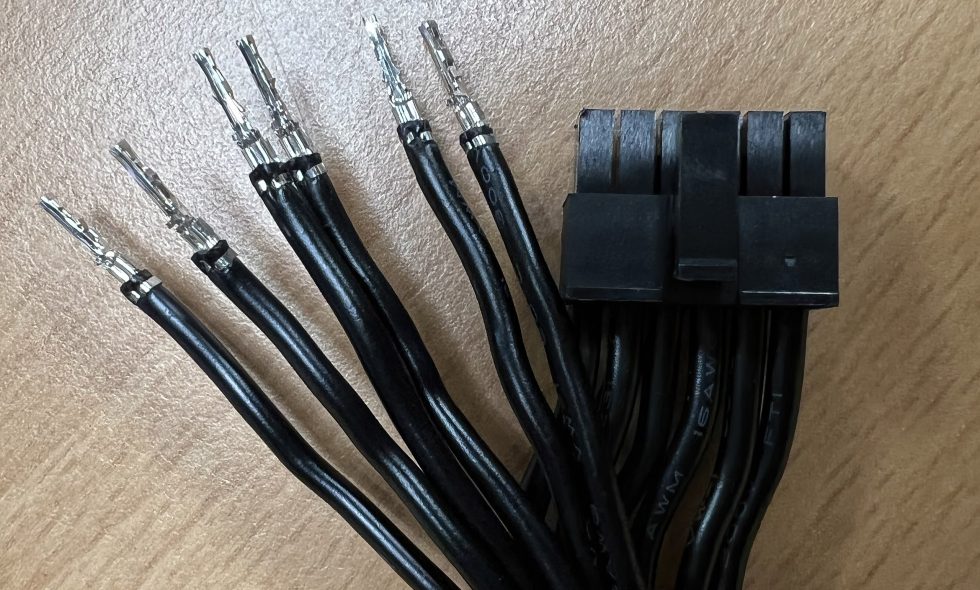

Crimping (also flanging, braiding or folding) is an alternative to other (electrical) connections such as soldering or welding. Such crimp connections are often found in the production of large series when single strands have to be processed on the assembly line. The connecting element is usually a plug (as in the 12VHPWR, see picture below) or a socket or you connect several wires to one (and then cover that with heat shrink tubing) as in the picture above.

Due to the strong pressure during crimping, the surface boundaries of the materials flow together, resulting in an almost homogeneous, well-conducting body! Crimping is far superior to soldering as a connection technique for stranded wire ends, especially whenever cables with thicker conductor cross-sections are to be used, as is the case here. A kind of air bubble almost always forms under the cooled solder, which leads to chemical activity and thus corrosion. But the key advantage of crimping is that neither solder (flux and solder) nor heat are used. And yes, the contact resistance is even lower in total and the connections usually last longer. Keyword “cold solder joints”.

The picture shows us again very well how these crimped contacts look like when they are pulled out of the 12VHPWR by force. And you can also see a kind of barb at the lower end of the contact surface, which secures the inserted contact against simply slipping out. It should be clear to everyone that these are not heavy-duty hooks. And that’s why we’re now coming to the second part of making things better, where it’s primarily the user who is called upon.

120 Antworten

Kommentar

Lade neue Kommentare

Mitglied

Mitglied

Mitglied

1

Urgestein

1

Mitglied

Veteran

Veteran

Veteran

Urgestein

Urgestein

Neuling

Veteran

Veteran

Urgestein

Urgestein

Neuling

Mitglied

Alle Kommentare lesen unter igor´sLAB Community →