Badly fitting coolers, too low performance with actually good waterblocks and bent CPUs – meanwhile not only the feedback of the readers is piling up, but also very similar reports from the board partners, cooler manufacturers and system integrators. Based on my own experiences, I went in search of clues and first tried to sort out emotionlessly what error patterns occurred. Finding a cause here is certainly not easy, as the phenomena are quite complex, but certainly not impossible either.

Now are the heatspreaders excessively curved or is the socket unstable? Are the specified (and unfortunately also necessary) contact pressures simply too high or are the mounting systems of the coolers rather useless? One could also speculate about too thin and flexible circuit boards and still not find a clear solution, because in the end it is probably a causal chain of which several factors are part of and from whose consequence the problems described then result. I had already reported in very detailed articles before the launch about Intel’s new socket including the mechanical peculiarities, so I would like to save myself this excursion into the details at this point. If you want to read it again in more detail, you are welcome to do so here:

I had already given various assessments of the heatspreader of the new Intel CPUs both in the unboxing article and at the launch and even praised it as quite flat and not particularly curved. I based this on my own measurements of the CPUs available at that time as a retail sample or engineering sample, which I had even checked in the 3D scanner. After testing over 20 CPUs, some of which were extensively measured, I was pretty sure the IHS would be a better fit this time.

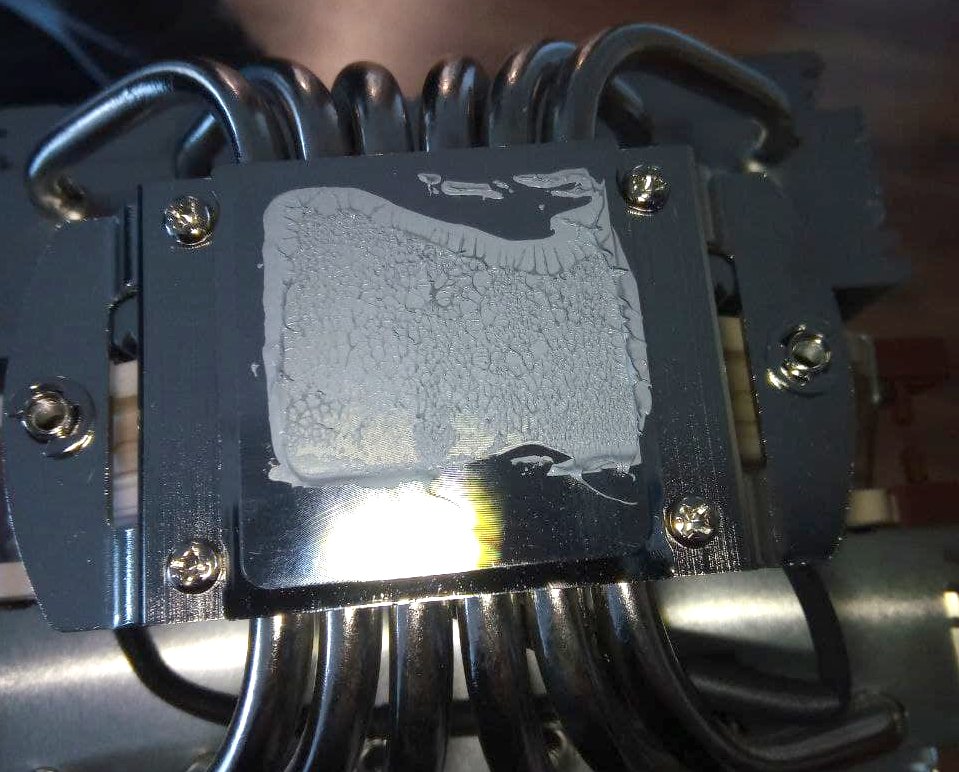

If you put it to the test, you can of course come to a different conclusion at first glance. Even cooler manufacturers like Noctua have noticed that the support of the coldplate / heatsink and thus also for the usable surface for cooling is far from optimal. The various cooler manufacturers are aware of this problem and it has been reproducible often enough (like here in the picture) with a new CPU as well as an unused motherboard including a brand new cooler.

I have to add at this point that it is not the fault of the cooler manufacturers and that Intel is still adhering quite well to the specifications for most CPUs (but not all!). And yet, it also hit us several times in practice, so today’s article was also created in cooperation and after consultation with motherboard manufacturers and cooler producers. This is because some of the companies have already experienced an increase in customer enquiries and even RMA cases relating to poor cooling.

In our case, depending on the water block, CPU and motherboard, there were up to 9 degrees (!) between the individual setups, which is far beyond possible tolerances. Also, the picture of the thermal paste after disassembly was very different and similar to the result in the picture above. But where do such imponderables come from, which affect even potent water cooling systems and drive the CPU into thermal throttling? In the next few pages, we’ll look at not only one of the possible causes that could have happened already before the launch of Intel’s 12th gen CPU which noone had considered before.

325 Antworten

Kommentar

Lade neue Kommentare

Mitglied

Mitglied

Urgestein

Urgestein

Veteran

Neuling

1

Veteran

1

Mitglied

Neuling

1

Mitglied

Mitglied

Urgestein

1

Neuling

1

Neuling

Alle Kommentare lesen unter igor´sLAB Community →