Causes of Noise and Vibrations

Even though a patent has been filed and there is immense interest in the solutions and their practical implementation, I have to find a suitable compromise with the depth of information today. Because I can measure more than Alphacool would surely like. I also know more from the prototype development than belongs in the public domain. Nevertheless, one has to delve a bit deeper to explain precisely why the concept and implementation are revolutionary and more than just “just another case fan.” And it starts with understanding the causes. When we look at the implementation and my measurements on the next page, I’ll remind you of these factors without having to go into them again. And we’ll see right away: The real nuisance is always the vibrations, which are often underestimated (also in their interaction).

Noise development in fans is unfortunately a very complex phenomenon influenced by many factors. In particular, the generated airflow, the motor, and the bearings play a central role in noise development. A better understanding of these factors can make fans more efficient and quieter, leading to an improved user experience and a longer fan lifespan. But try telling that to rampant marketing or the stingy controller.

Trailing Edges and Turbulence

When thinking of a fan and its noise emission, the primary concern is “wind noise.” These broad-spectrum noises often arise from interactions of airflow with trailing edges, resulting in turbulence and low-frequency vibrations. A trailing edge refers to a sharp or abrupt edge on a solid body where the adjacent flow loses its adhesion and is torn off. This detachment leads to turbulent flow behind the edge. In fans, such edges can occur on the fan blades, the frame, or other parts of the fan system. The resulting turbulence can also lead to vibrations in the structure, which are then radiated as sound waves into the surroundings.

Turbulences are small, chaotic airflows that occur when laminar flow transitions to turbulent. They are small vortices in the flow that contain energy. When this energy is transferred to surrounding structures in the form of vibrations, it can lead to acoustic emissions. They can be caused by trailing edges but also by other factors such as the shape of the fan blades or obstacles in the airflow.

When writing about the topic and the changes, one must also consider the so-called separations. And don’t worry, I’ll try to simplify things a bit. There are places where the flow can no longer follow the contour of a body and then detaches from its surface. In these separation areas, the air shows strong turbulence and appears chaotic in time and space. The velocity in such areas is so low that they are often referred to as “dead zones” caused by the friction between two parallel flows with different velocities. The “wave breaker” on the front side of the rotor blades of the Alphacool fan might be debatable, as I don’t see a real advantage here. But it doesn’t have a disadvantage either, so let’s just chalk it up to “visually valuable” and “looks technical.”

In general, there are two main causes of separations: pressure-induced separation caused by a sufficiently large positive pressure gradient and shape-induced separation due to geometry, such as a sharp edge of a body. The boundary layer of a body flows against the static pressure generated by the external flow. If the moving air near the wall of the boundary layer does not have enough kinetic energy to overcome a strong pressure increase, it reverses, and the boundary layer detaches from the contour. The contour’s nature significantly influences the place of detachment. Turbulent vortices, due to the intense lateral movements of the molecules, have a stronger momentum exchange near the edges and boundaries. This partially compensates for the loss of kinetic energy and increases resistance to detachment.

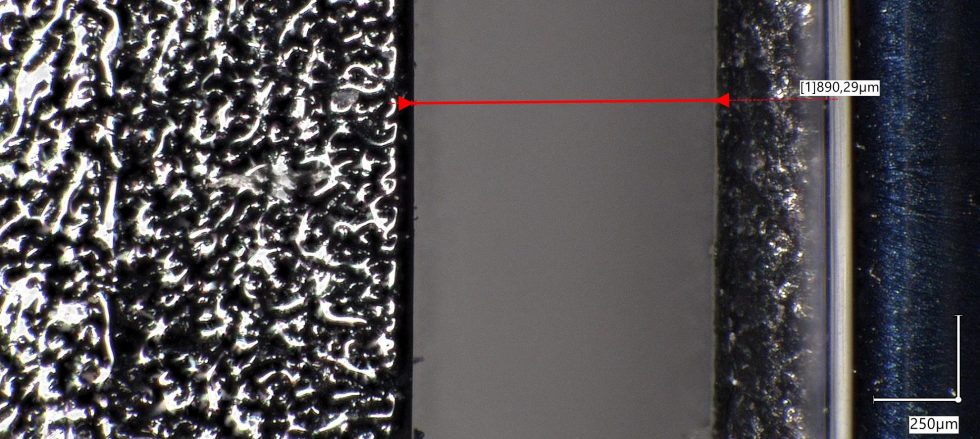

To minimize fan noise caused by trailing edges and turbulence, various approaches can be pursued. One approach to delay detachment is, for example, optimized rotor blade geometry, the surrounding enclosure of the rotor blades, and the surface finish. Often you see gimmicks like “winglets” or kinks in the rotor, but they are more for optics and marketing. Most of the time, they are even counterproductive, but oh well. The picture above shows what is really useful. The smaller, pre-built “separator” reminiscent of the Taylor bug on large ships. This small attachment essentially creates its own small “airwave” and thus shifts the rotor blade’s wave image slightly. So you need less energy for the same performance, which is also applied to ships.

Motor Noises of All Kinds

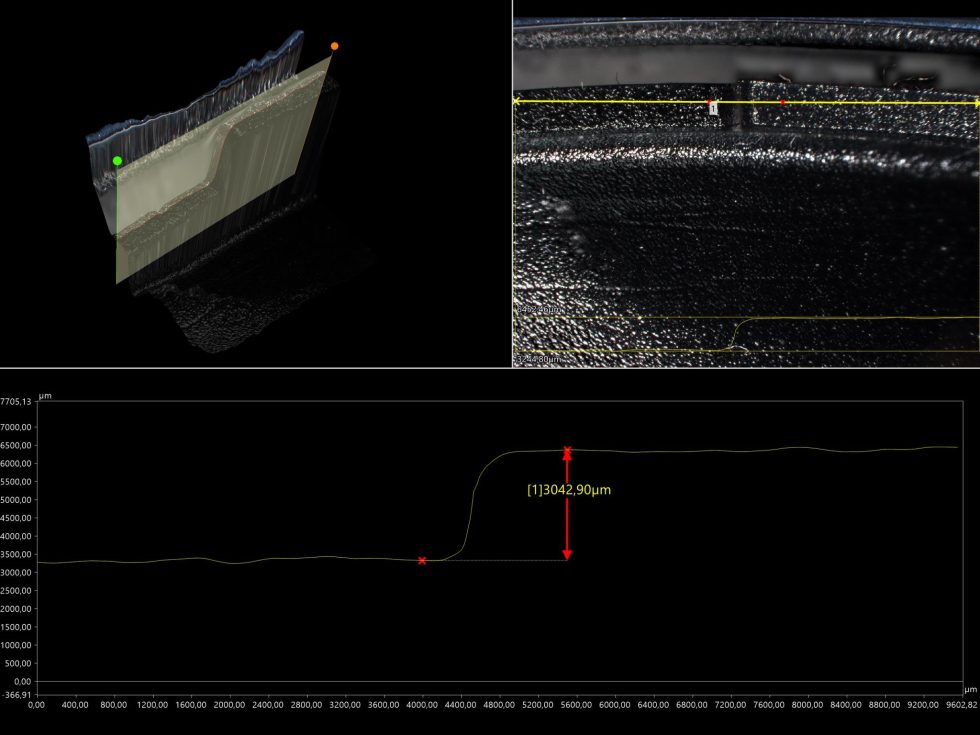

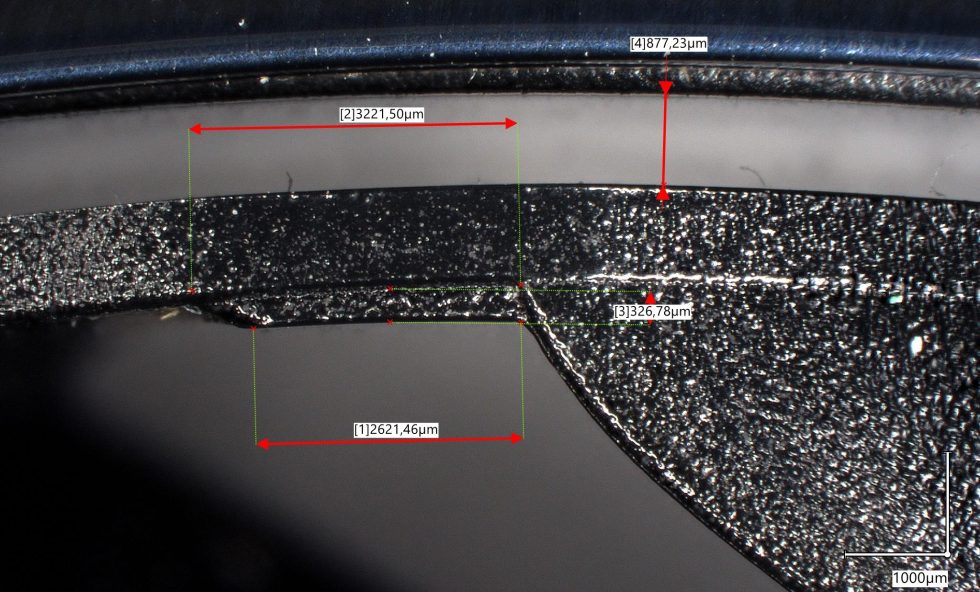

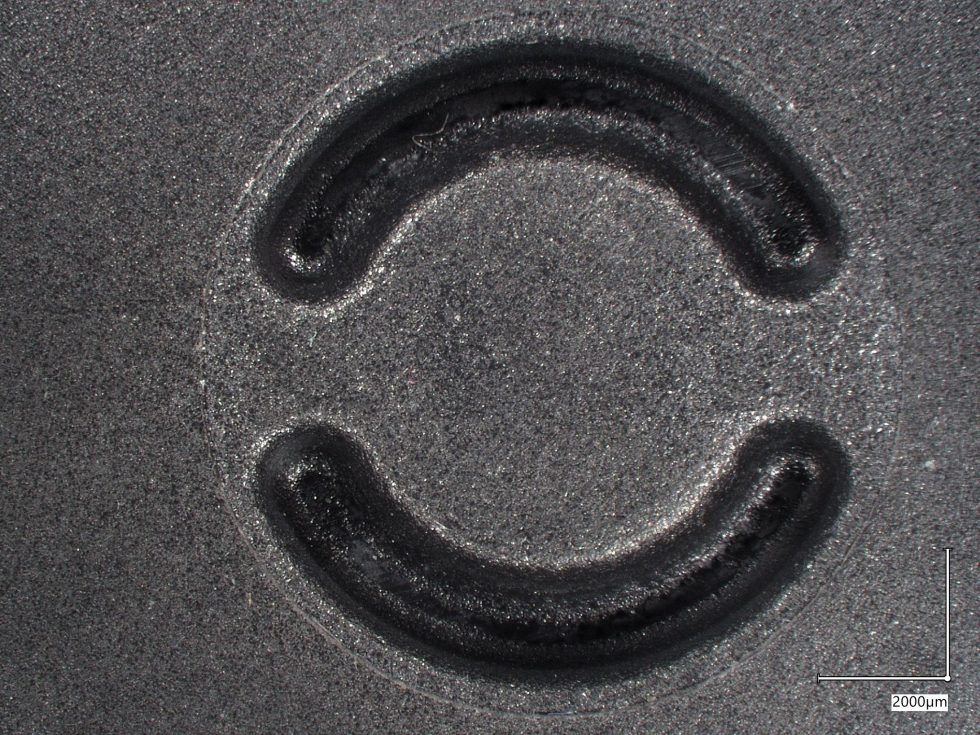

In the picture below, we see the structure of the new fan from the early prototype stage and the 4-pole motor. The final product even uses a 6-pole motor. Why is also evident from the following text. So I’ll summarize everything related to the drive that also produces audible vibrations and other noises. Back to the motor: Normally, the impeller, the actual rotor that also contains the permanent magnet and the motor axis, sits on the rigidly mounted bearing bush of the immovable stator, and the respective coils and circuit board are arranged around this axis. All of this is firmly mounted on the fan frame in conventional fans, which represents the stator as a whole and thus absorbs all vibrations (and happily passes them on).

But what motor noises are there in detail? The whole thing is a nasty mix! On the one hand, there are electromagnetic noises caused by the interaction of electrical and magnetic fields in the motor. Especially with PWM-controlled motors, these noises can be influenced by the pulsing of the current, and the electronic whine comes on top with a bit of bad luck. Then there are the mechanical noises resulting from the physical movement of the motor and irregularities in the motor winding or the general structure. Every motor also has one or more resonance frequencies at which it can become particularly loud. If the fan is operated at one of these frequencies, this can lead to increased noise levels. And because car comparisons are so popular: Six-cylinder engines run smoother and softer than four-cylinder engines.

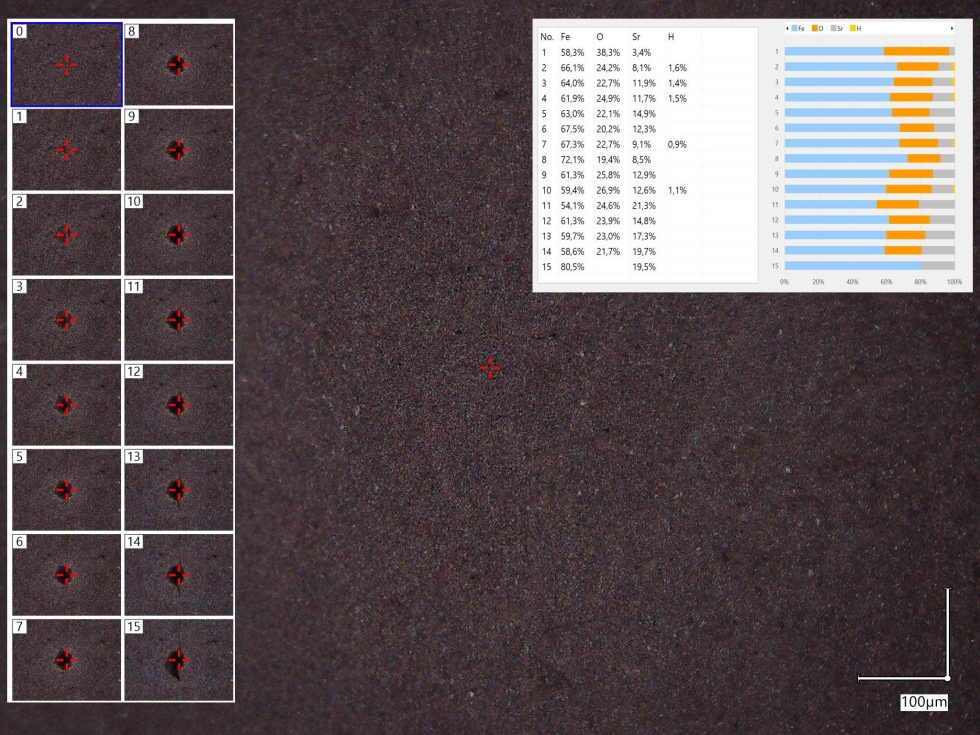

The fan uses strontium ferrite in the impeller’s circulating permanent magnet, also known as SrFe12O19. It belongs to the class of hard ferrites and is often used in permanent magnets because it has excellent magnetic properties. It offers high remanence and coercive field strength and a very high energy product, making it one of the strongest permanent magnets. Compared to other magnetic materials such as neodymium or samarium-cobalt, strontium ferrite is more cost-effective. Strontium ferrite magnets have good temperature stability, and they retain their magnetic properties even at high temperatures, making them suitable for applications like electric motors that generate heat. Compared to other magnetic materials, strontium ferrite has the advantage of containing fewer rare earths. This makes it more environmentally friendly and reduces dependence on rare earths, which often come from geopolitically insecure regions.

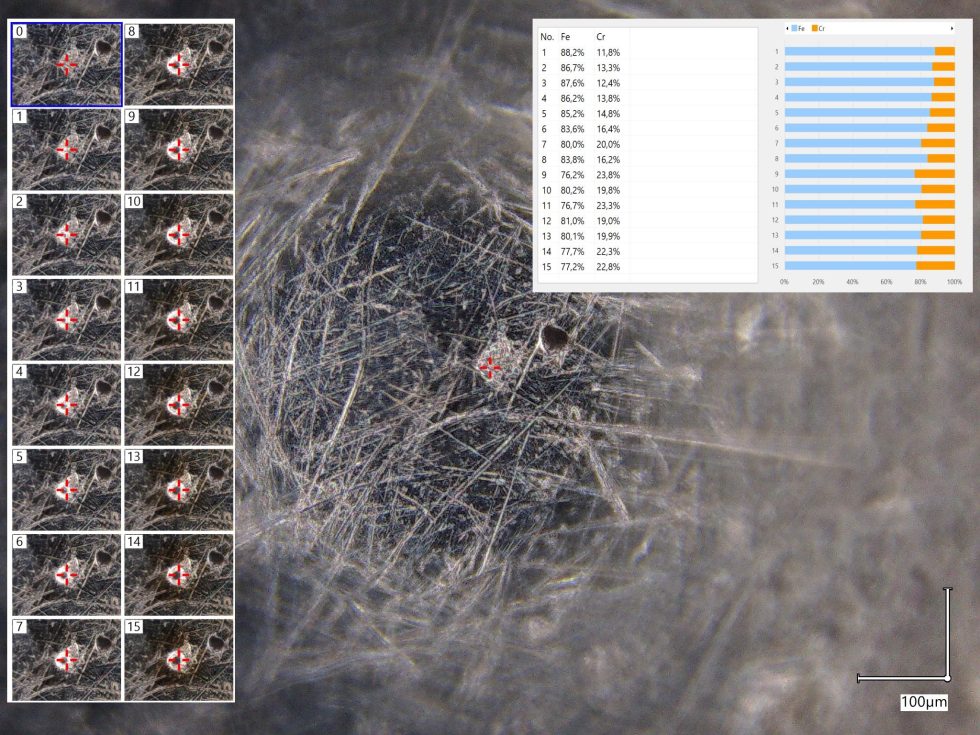

Of course, bearing noises also belong to mechanical noises. The fan’s bearing allows the fan blades to rotate with low friction, and unfortunately, a lot of marketing gimmicks are used in this area. What’s the use of the best bearing if the rest doesn’t fit? Practicality and durability are key, and the rest must also match the motor’s characteristics. Much is simply “overengineered,” and personally, I value longevity more than technical frills that only read well in datasheets. However, an axis made of chrome steel with a very high chrome content, as with the Apex Stealth, is always a safe bet.

Despite the use of lubricants, friction can occur in bearings, causing additional noises. But this can usually be neglected because there are much worse factors. Over time, bearings can wear out, leading to irregular rotation and annoying noises. An improperly aligned bearing can also lead to uneven loads and vibrations, which in turn produce additional noises (clicking, grinding, humming). Like the motor, bearings can also have resonance frequencies that lead to increased noise levels when excited. Even the best floating bearing doesn’t help here, as it also offers resonances. It is then more sensible to decouple the bearing itself somewhat. Then a good hydrodynamic bearing like the Apex Stealth will do just fine.

Interim Conclusion

As we can see, a little theoretical excursion doesn’t hurt to understand the complexity. Alphacool was smart and kept it relatively simple at this point: They identified the actual problem of current fans as the sum of all emerging vibrations and looked for a general solution. This measurable and audible mix of impeller vibrations, which are also transmitted to the axis through body sound, all the vibrations from the drive, and the interaction with the resonance frequencies of the impeller, motor, bearing, and stator (frame), is the starting point for trying to eliminate these vibrations as a bundle in one go. How this was achieved will be explained on the next page.

- 1 - Introduction and technical data

- 2 - Causes of noise development and vibrations

- 3 - The secret of decoupling and the used material

- 4 - Apex Stealth Metal Power Fan: Measurement results in detail.

- 5 - Comparison with the Noctua NF-A12x25 PWM (2023)

- 6 - Comparison with the Be Quiet! Silentwings Pro 4

- 7 - Comparison with the Cooler Master Mobius 120

- 8 - Summary and conlusion

977 Antworten

Kommentar

Lade neue Kommentare

Veteran

Veteran

Urgestein

Urgestein

Urgestein

Veteran

Urgestein

Veteran

1

Urgestein

Urgestein

1

Urgestein

Urgestein

Veteran

Urgestein

Veteran

Urgestein

1

Alle Kommentare lesen unter igor´sLAB Community →