But technical consulting and external quality control aren’t the only things on the daily schedule; media relations will certainly benefit enormously from the device. To maintain and expand reach, you can either hire people and produce more content, or use the existing equipment in a targeted way to stand out from the competition. Niche instead of news? Why not? The part also doesn’t come with annoying non-wage costs and doesn’t lock in expensive overtime. Joking aside, you can use what’s there and be happy not to have to have expensive external appraisals done if you ever want to know more details.

The classic running gag: NVIDIA’s 12V socket on the graphics cards

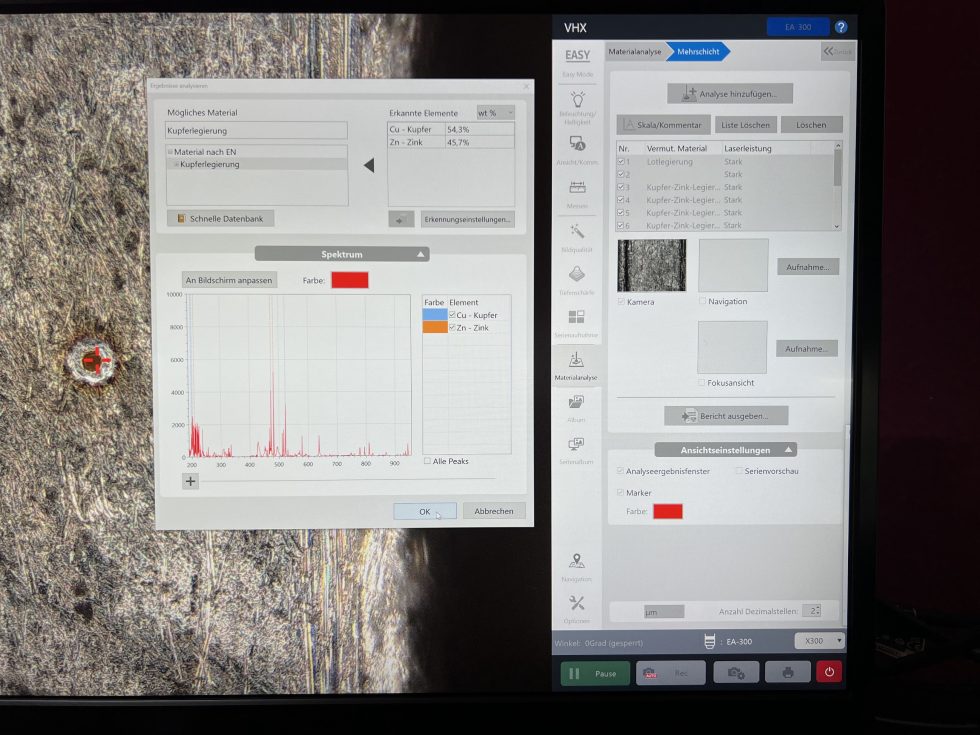

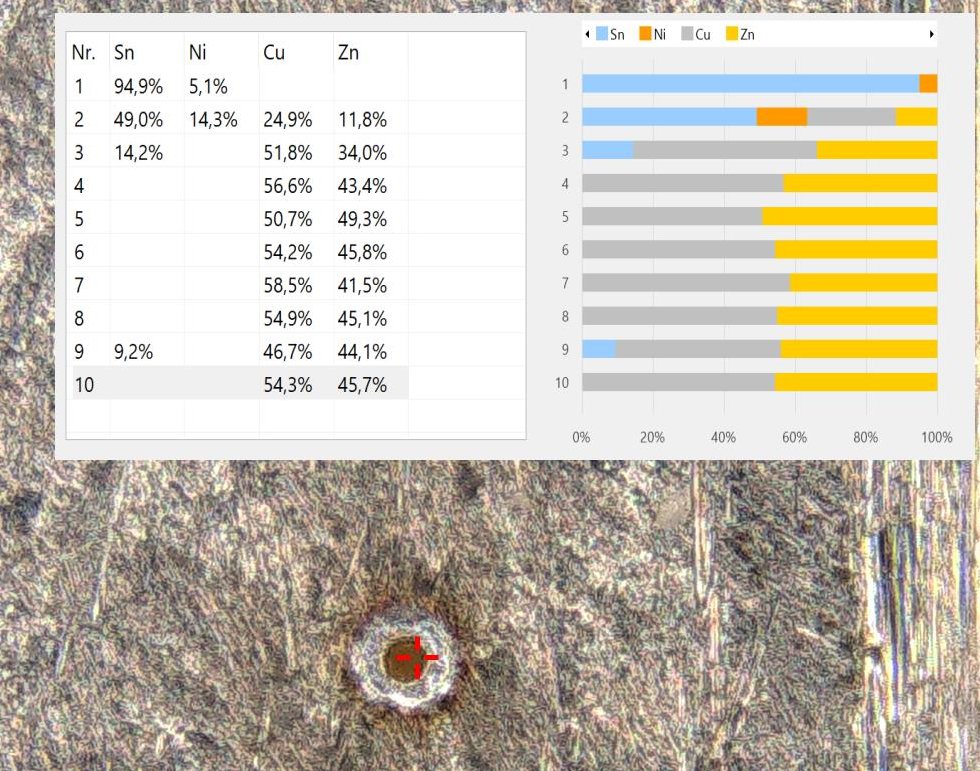

At this point, I don’t want to anticipate an article that is currently in progress, so I’ll take a GeForce RTX 3080 as a representative, which is lying disassembled on the shelf of good deeds anyway. I’m curious what the pins of the sockets are made of, for example, on which the ominous spring contacts are then pushed. Well, that alone is of course not an article, but a good piece of the puzzle for a proper insight. Because this material is not really put together in the same way on all cards.

By composite, I mean the alloy used, of course, because it cannot and must not be pure copper, that would be much too soft. Again, I shimmied through the layers and what did I find? Brass! Ok, that was actually clear.

In the back we have the tinned connectors, but this layer is quite thin on this older Astron connector and it ends at the end of the third shot. However, the table always shows a very large amount of zinc from shot 4 on, which is not necessarily advantageous.

Indeed, the conductivity of brass is strongly dependent on its zinc content. Brass is an alloy consisting mainly of copper (Cu) and zinc (Zn). While pure copper has a very high electrical conductivity, adding zinc reduces this conductivity. In general, of course, the higher the zinc content in the brass, the lower the electrical conductivity of the alloy. The common yellow brass (70% Cu, 30% Zn) is very often used for technical applications and has a noticeably lower conductivity than medium brass, but the measurement of the pins still tends towards the slightly worse white brass (<50% Cu, >50% Zn).

With a very high zinc content, this alloy has much lower electrical conductivity, but is more stable. It is important to note that other factors such as temperature, contamination, impurities, or processing can also affect the conductivity of brass. I repeated this measurement several times and at different locations as well as pins, and also used different laser power. However, the average remained about the same.

The socket housing is made of nylon and this is exactly where I can stop. Since I know what chemical elements are found in nylon (polyamide 6 and 6.6), I can rule out at least some other materials. Nylon is made exclusively from inorganic substances such as carbon, water and oxygen. If you find these, you can de facto stop. That’s all you get measured.

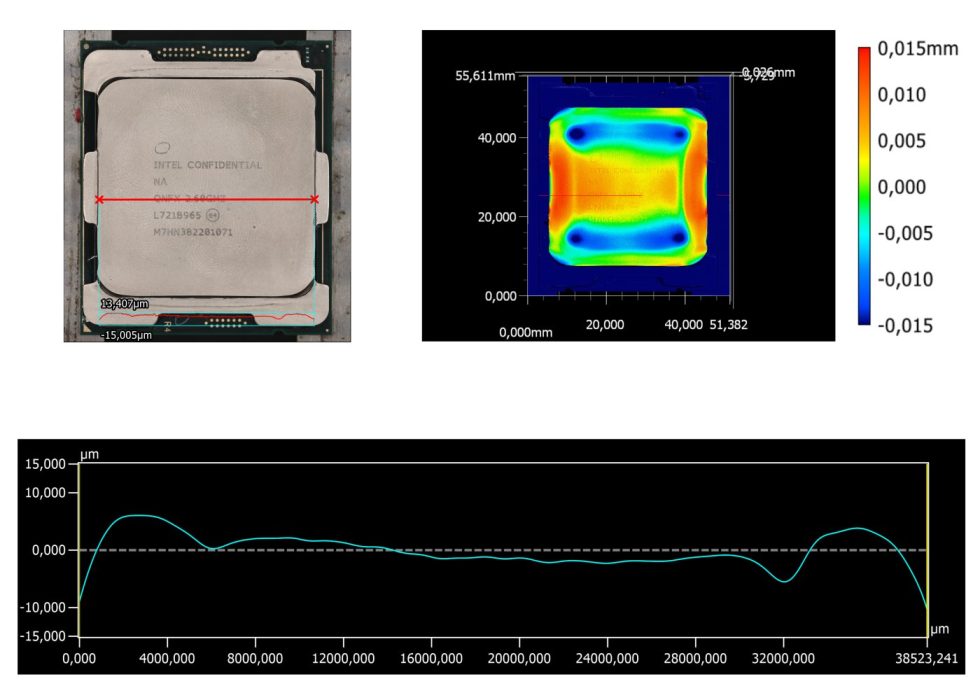

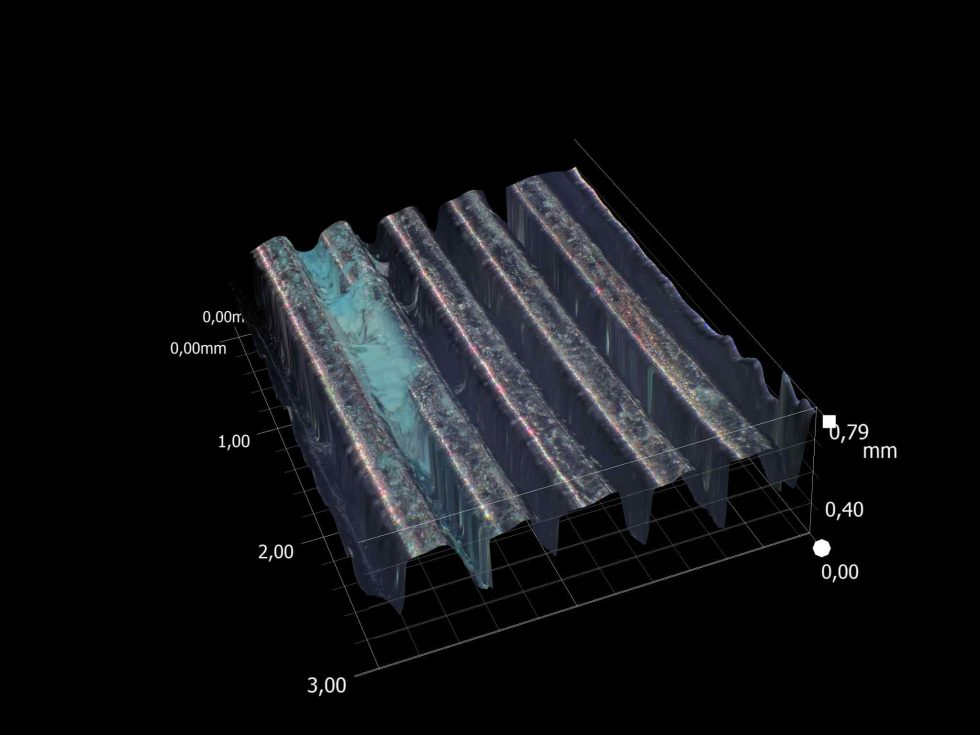

I will write something about the 3D profilometer in due course, I am currently lacking practical examples and in this context I would like to remind you of the study on IHS, which I published some time ago:

Here come yes in the foreseeable future again new bolides and it will be a pleasure for me to test these accordingly. And also the radiators, AiO problems and other small brainteasers can be solved nicely here. Sure, you can’t analyze organic compounds, but often it’s enough to examine the accumulated residues for their chemical elements. Because that is then quite clear.

Although I have already done such investigations for some of the suppliers and can do more in the future, the media work will of course benefit equally. Then there is once again one news less and instead exciting investigative articles. Okay, I have one more, but I’ll save it for the last page. So please turn the page again!

34 Antworten

Kommentar

Lade neue Kommentare

Urgestein

Moderator

1

Veteran

Urgestein

1

Veteran

Urgestein

Veteran

Mitglied

Urgestein

Neuling

Mitglied

Urgestein

Urgestein

Mitglied

Mitglied

Urgestein

1

Alle Kommentare lesen unter igor´sLAB Community →