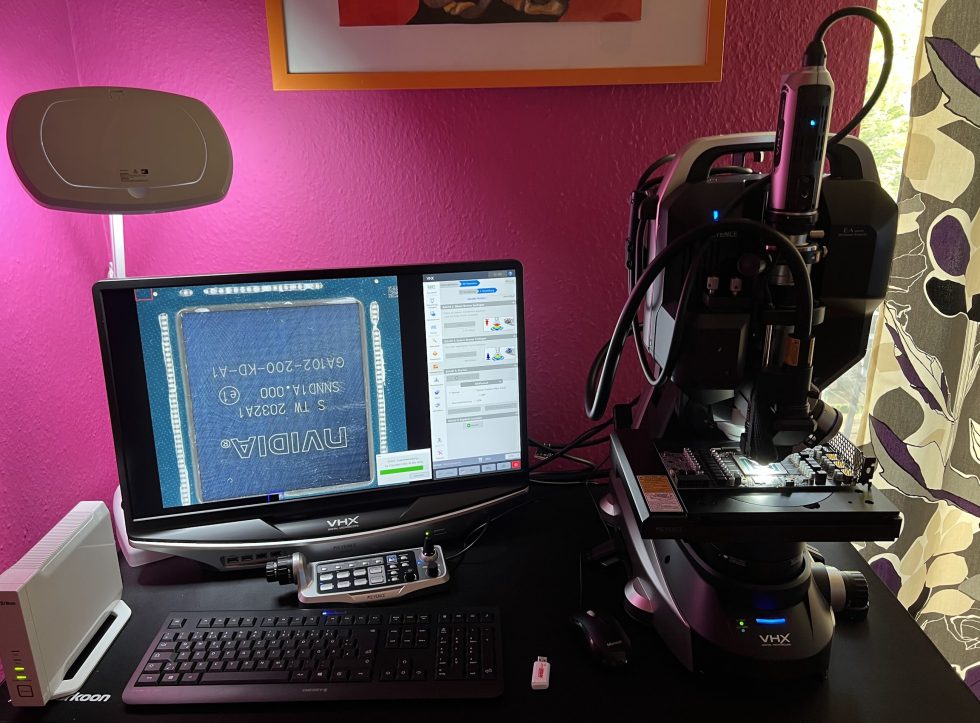

You can invest a lot of things for and in something. Time, energy and, of course, a lot of money. But if you take the latter in hand, on the one hand to save time and energy, and on the other hand to test or uncover things that your normal (media) competitors can’t, then something like this is well worth it. After all, I have two mainstays and one of them is the lab. Synergies with the website are quite intentional and so in the end there is also a nice win-win situation for my readers, the clients in the lab and in the end of course me.

Yes, I have long thought back and forth, whether I buy something like this myself (always keep an eye on the ROI!) and I admit, it was initially also associated with some stomach ache. It’s not quite that cheap, even if it doesn’t bankrupt me. But the monetary security for a comfortable pension gets there already slight scratches. Nevertheless: Close your eyes and go for it, and yes, I have not regretted it. I could also have written “no” at this point, and the message would have been the same.

And what do you do with such a device? The 3D profilometer and the powerful microscope (max. x2000) are of course interesting and are used with pleasure (I only remember Ampere and the bending of the GPU), but I was primarily interested in the material analysis for which I do not have to use a SEM EDX. Vacuum? I don’t need it anymore and it saves a lot of time. As long as you know what you’re getting into and where the limits of the method you’re using are, it works really well. And that’s exactly why I want to show you a few examples today of what happens outside the website and what else you could (and can) use such a nice machine for.

Some theory in advance and the first case: Toxic adapter cables and a real shock

Laser-induced breakdown spectroscopy (LIBS), which I am now using, is a type of atomic emission spectroscopy in which a pulsed laser is directed at a sample to vaporize a small portion of it, creating a plasma. The emitted radiation from this plasma is then analyzed to determine the elemental composition of the sample. LIBS has many advantages over other analytical techniques. Because only a tiny amount of the sample is needed for analysis, damage to the sample is minimal. This technique generally requires no special sample preparation. Even solids, liquids and gases can be analyzed directly. This is exactly what I could not do with the SEM EDX. I had to wash out all liquids before (vacuum!).

LIBS can detect multiple elements simultaneously in a sample and can be used for a wide range of samples, including biological, metallic, mineral and other materials. And you get true real-time analysis, which saves tremendous time. Because LIBS generally does not require consumables or hazardous reagents, it is a naturally relatively safe technique that also does not require a vacuum. As with any analytical technique, there are limitations and challenges with LIBS, but in many of my applications, especially when speed, versatility, and minimally invasive sampling are advantages, it offers distinct advantages. And that’s exactly why we’re going to make a cut and get to the first really, really serious example.

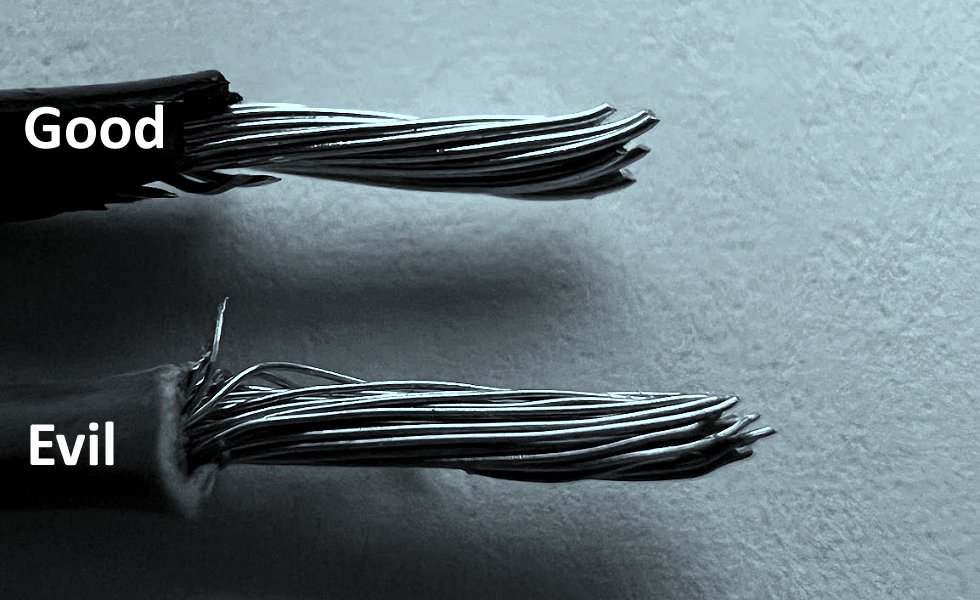

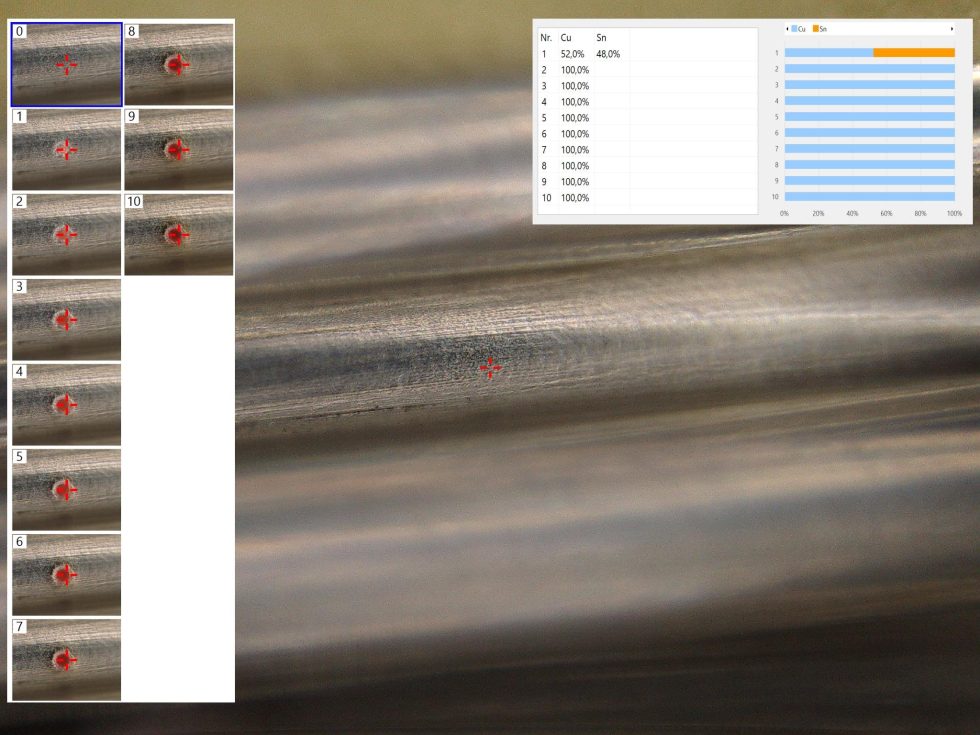

Cables for computer power supplies often don’t get a closer look unless you at least check the cross-section. And one assumes that it is pure copper anyway. But copper is expensive, and many of the mining methods and copper ore sources are neither safe nor clean. We’ll see in a moment how little, and understand why such controls are immensely important, including for the health of customers. I’ve been digging through some power supplies here on assignment and testing the cables there. Ideally, and here I have to praise the manufacturers or suppliers in general, it all looks nice and safe. Exemplary an adapter cable from Cablemods: Outside the thin layer of tin and then comes in the depth nothing more than pure copper. On the left, I have documented how the laser eats further into the depth with each shot.

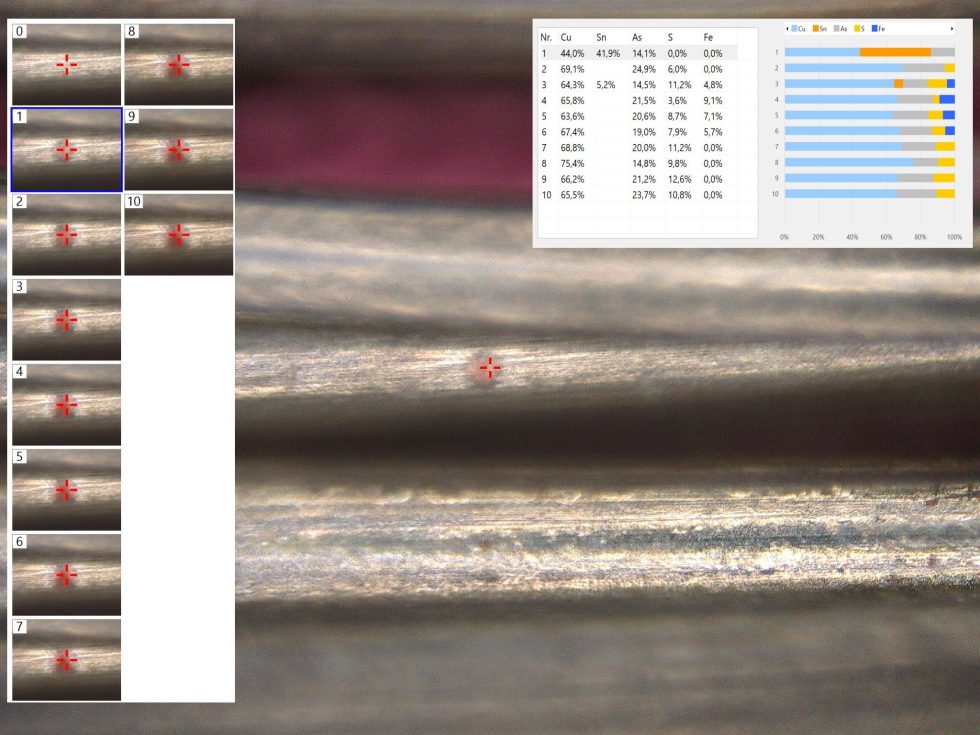

And now we come to the technical full burn. I thought about where I could get a counter example. I found it at the end with an old and super-cheap eBay “gaming” power supply. With great 750 watt print and highly labeled Linkworld board (5 volts and 3.3 volts as focus). The PSU was a potential fire starter in itself, so I suspected no decent cables either. And bull’s eye! Now look at this, it’s even highly toxic! Apart from the sulfur and iron contamination, the arsenic content is downright criminal! And the individual wires were extremely brittle and fragile, feat.

Arsenic is an element that occurs naturally in many copper ores. However, arsenic is highly toxic and long-term exposure can lead to a variety of health problems, including skin problems, cancer and negative effects on the nervous system. When copper is contaminated with arsenic, it can affect its electrical properties, which is particularly problematic. In addition, arsenic contamination in copper alloys can lead to reduced mechanical strength. Therefore, it is often necessary to test copper products for arsenic to ensure they meet specified standards.

To overcome these problems, refiners must use methods to remove arsenic as completely as possible from copper such as oxidative processes or the Toowong process. This in turn, of course, results in higher costs. And this closes the loop, because it can already happen that particularly inexpensive products rely on contaminated copper. But this must not be the case, and I also feel challenged to a certain extent to help ensure that something like this is detected before the products reach the customer.

34 Antworten

Kommentar

Lade neue Kommentare

Urgestein

Moderator

1

Veteran

Urgestein

1

Veteran

Urgestein

Veteran

Mitglied

Urgestein

Mitglied

Mitglied

Urgestein

Urgestein

Mitglied

Mitglied

Urgestein

1

Alle Kommentare lesen unter igor´sLAB Community →