Due to a given occasion, I now even have to add a third part to my water cooling investigations. It will unfortunately show what happens when you combine (without knowing it) an aluminum cooler with copper components and I will specifically question why the result turns out so extreme, as in this case. Of course, you also have to differentiate the whole thing, which I will do in the course of this test. However, the fact that this card seems to have been taken off the market in secret does not make things any easier. The product page is still online, but the product no longer appears in the listing.

By the way, the two preceding articles are really important reading recommendations for a better (technical) understanding. So if you haven’t read it yet, you should definitely do so!

|

|

|

Important preliminary remark

I’m not a fan of any bashing or click-baiting at the expense of individual manufacturers, but this exact card is a perfect lesson in what can happen when you have a waterblock produced as cheaply as possible. If there are obvious quality defects in production and quality management fails spectacularly, marketing suggests a copper block to the customer in advance via the media, and the customer designs his cooling system accordingly, then total failure is only a matter of time.

Even serious websites unfortunately only quote the marketing text here and you read amazing things like: The GIGABYTE RTX 3080 Gaming OC WaterForce WB uses nickel-plated copper as its primary material for the water-block, capped by an acrylic top that’s mostly covered by a plastic+metal shroud.

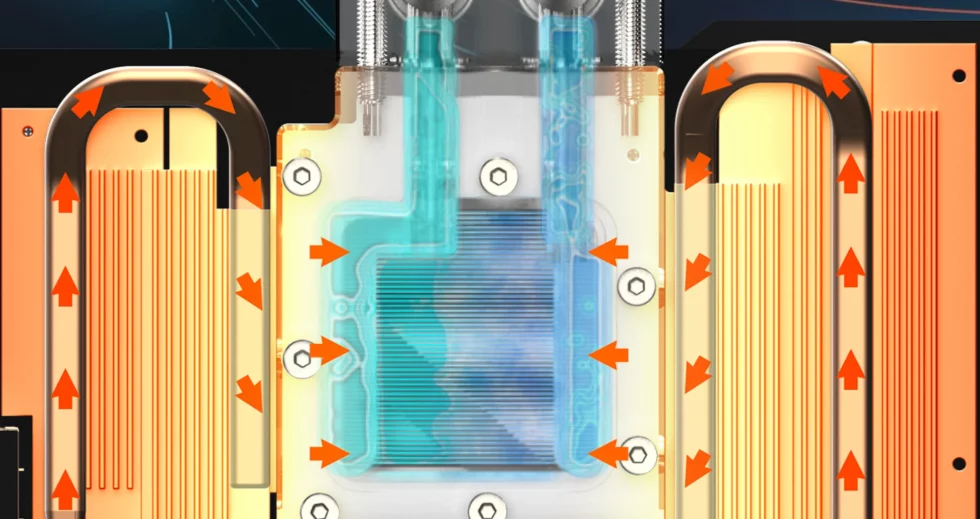

In addition, there are the company’s own render images, which also suggest copper and which have been spread on many websites. But what is the customer to believe when the manufacturer’s website does not even provide any information about the material?

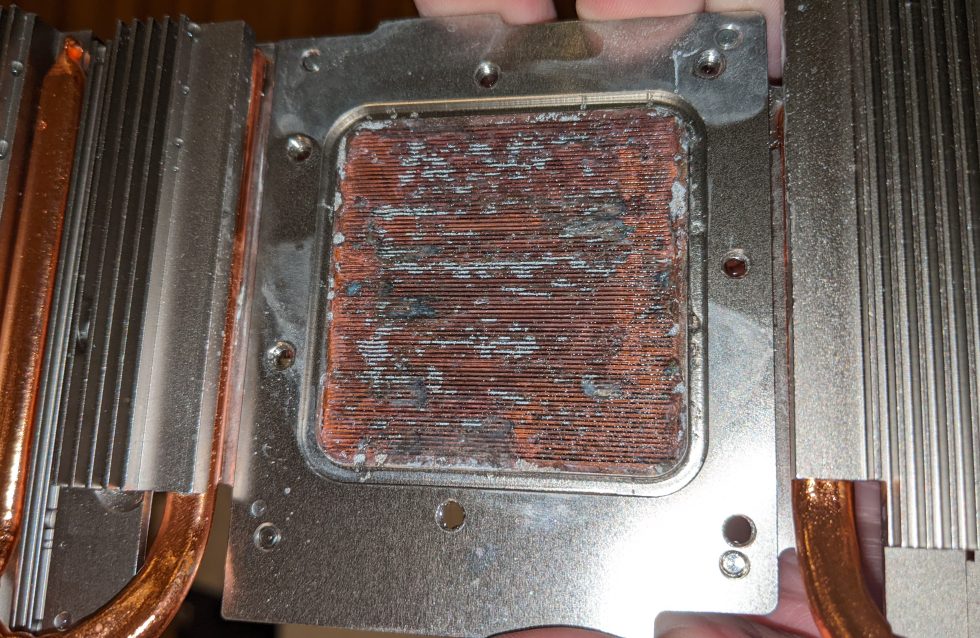

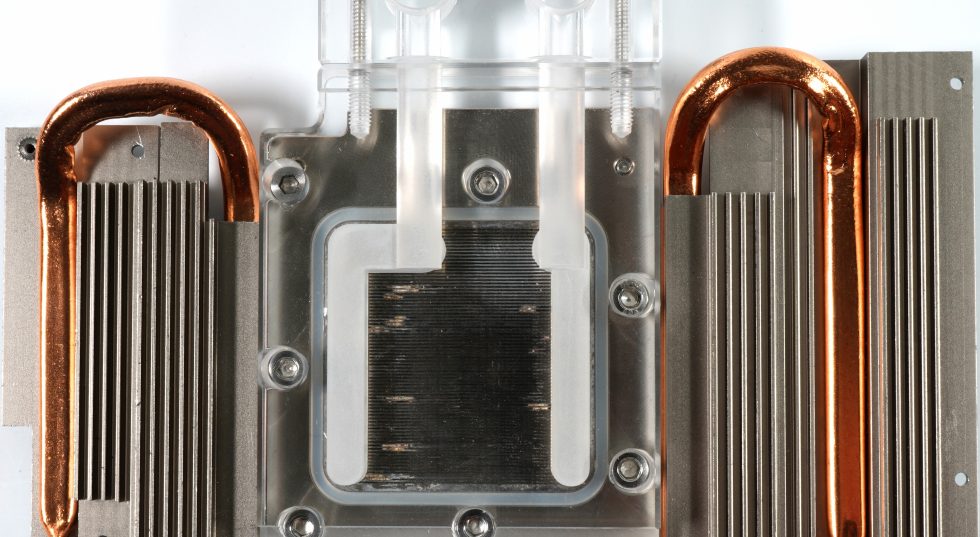

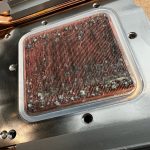

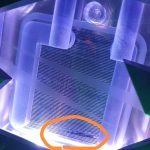

Unfortunately, the reality is different, because it is NOT copper, but the cooling block is completely made of simple aluminum. They at least anodized the part above the GPU, however, I’ll have to comment on that later as well because I’ll also be questioning the anodizing and production process. The two brazed heatsinks for the voltage converter rows, on the other hand, are untreated and the two heatpipes are rather decoration. The double thermal transfer resistance of the contact layers alone suggests that a solid monoblock made of aluminum would actually have made much more sense.

But optics and marketing meet low-cost manufacturing here, because machining a thicker aluminum block would also mean that costs would rise significantly. Such a patchwork is cheaper to manufacture and you can also use it for an AiO compact water cooling and thus save tooling costs. Or it was the other way around and the custom loop variant uses the remains of the AiO manufacturing.

The consequences of this planned misunderstanding are unfortunately serious. My article today is based on a total of 7 (!) different cards from different users, of which one cooling block was tested very thoroughly by myself. The data and pictures of the other 6 cards were provided to me by the buyers (there are also countless Reddit threads on the subject) with kind support and a written permission to publish. All cards or systems presented here were affected by a total cooling failure and had to be converted to alternative cooling blocks at great expense. RMA? Either the warranty had expired, or the users helped themselves right away.

Overview of 6 of 7 failed cards

Before I start with the examination of the seventh card, I would like to introduce the images of the other 6 cards. By the way, the last of the systems was even leaking at the end, because the corrosion had eaten through completely. The image quality of the documentation provided varies greatly, but you can always tell what really happened. That alone would not have been worth a longer article, but what I was able to find out from the other card is a real lesson that I do not want to withhold from you. Of course, there is also the obligatory additional information about the manufacturing details.

All systems were filled only with distilled or DEMI water (e.g., reverse osmosis water), as well as with the appropriate additives including anti-corrosives, according to the statements of the users concerned. Incidentally, one of the reasons for a more detailed surface analysis was the different coloration of the clogging layer or crystals from card to card, which ranged from the expected turquoise-colored tone to yellow-brownish. We like to remember my last article on aluminum brazing (see above for the link to the flux). But more on that in a moment.

70 Antworten

Kommentar

Lade neue Kommentare

Mitglied

Moderator

Veteran

Mitglied

Veteran

Urgestein

1

Veteran

Urgestein

Veteran

Urgestein

Urgestein

Urgestein

Urgestein

Mitglied

Mitglied

Urgestein

Mitglied

Alle Kommentare lesen unter igor´sLAB Community →