Thermal paste instead of solder

One of the reasons for the whole cooling problem is Intel’s use of inappropriate (but probably much cheaper) thermal paste instead of a sensible indium-based solder. The durability of such thermal transitions, including theoretically hairline cracks that might occur in long-term use, can be discussed and profiled, but other chip sizes have been operated stably and flawlessly with solder for years.

In addition, there is the fact that the pastes used, in contrast to a good solder, are also anything but stable over the long term. Every paste has a tendency to so-called oiling out, in which the binder actually escapes from the paste and creeps away. This curing and creeping effect occurs to varying degrees in all pastes, but it can never be completely prevented.

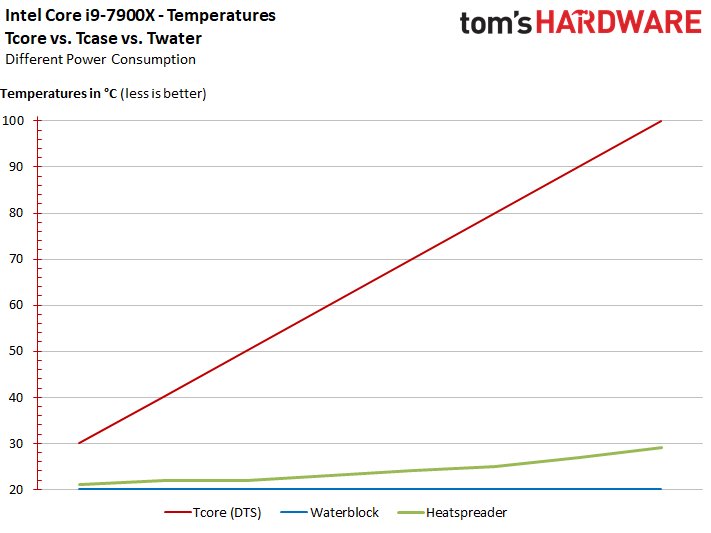

But why do we insist so stubbornly on this fact? The following curve from our launch article on the Intel Core i9-7900X, which we determined with a potent chiller (!), shows extremely clearly that the waste heat can only be dissipated poorly and insufficiently! What just about worked with a thermal 100-watt saver, like the Core i7-7700K, now leads the paste strategy to absurdity. Those who are interested can read more about the exact method of our survey in the launch article linked above.

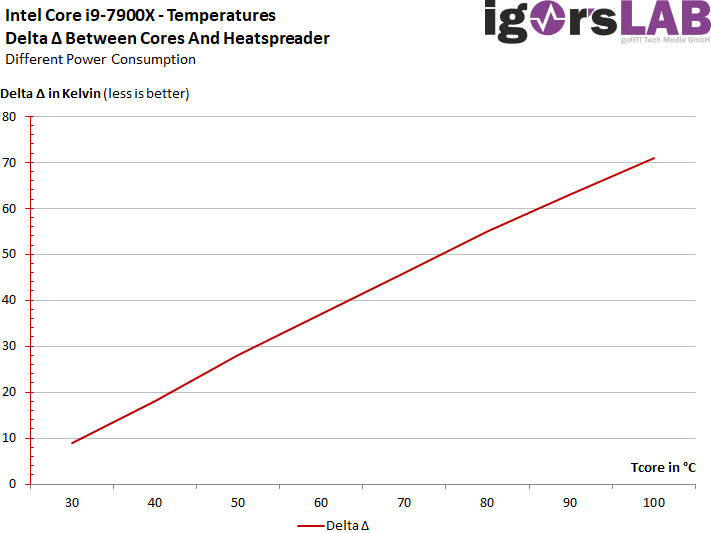

In the end, the following curve represents the blatant temperature differences between the heatspreader’s upper side and the cores. The results shocked us back then and still do:

Although we used pretty much the best and most expensive on the market with our chiller, the Alphacool XPX water block and the Thermal Grizzly Kryonaut thermal paste, we ended up with a whopping 71 Kelvin as the temperature difference between the temperature of the cores and the top of the heatspreader on the bill! This is especially annoying in that it makes normal cooling solutions look quite silly under full load and factory clock. AMD has impressively demonstrated how such power consumption values can be better dissipated with the Ryzen 7, even though the game with the artificially offset output values of the X models pissed us off.

Malicious tongues also claim that Intel has deliberately chosen the inner structure in such an inexpedient way in order to just about make it possible to use the CPU in delivery condition and with standard BIOS settings, but to elegantly exclude extreme overclocking. We cannot judge or even claim that, but the conclusion as such has a certain charm.

Leaflet #2

The dissipation of the waste heat based on the CPU’s power dissipation is severely limited or made more difficult by the CPU’s special construction and the use of counterproductive thermal paste (TIM) between the heatspreader and the die. No matter how great the contact pressure and how low the temperature of the cooling heatsink, the CPU’s full potential can definitely not be exploited this way.Intel has deliberately or unintentionally installed a thermal brake that could not be more unnecessary.

Heads as a way out? Yep.

Of course, you could be tempted to simply remove the heatspreader including the thermal paste and thus dispose of the cooling problem for good. However, such an action isn’t really suitable for everyday use for every bona fide user. If you want to do it yourself, you first need a suitable tool, a lot of skill and also a lot of experience. Of course, you also lose any manufacturer’s warranty.

Various business models are now based on this (and on the convenience or fear) of the buyers, which start exactly there and offer the suitable tool or sometimes even ready-made CPUs with and without warranty. Easily digestible fast food for Kevin Normal overclockers? Not at all, because such a bare die is more sensitive and also more difficult to handle than the advertising icons of the relevant freeloader industry would like to tell you.

Symbolic image: one of the frequently used head aids (source: Aqua Computer)

Symbolic image: one of the frequently used head aids (source: Aqua Computer)

Of course, you can minimize or eliminate possible mechanical damage caused by an uneven and/or too high pressure load by counting the number of turns of the screws when tightening the cooler, as well as by using a good torque screwdriver, but it is and remains a risk. In addition, the resale value drops enormously and any warranty claims may be forgotten immediately.

Once again, without polemics, but with the necessary respect for the expensive product and its buyer: if you know and can calculate what you’re getting into, you can solve any number of thermal problems in one fell swoop. Can, mind you.

But for the large mass of prosumers and perhaps gamers who want to use such a system for many other tasks besides gaming, beheading is nothing. Because long-term experiences with the Skylake-X do not exist yet and the price that normal buyers have to pay for these products themselves in the form of their own money is extremely high.

Leaflet #3

Beheading is a solution to the cooling bottleneck, but nothing for the masses. The beheading itself, or the (subsequent) use of CPUs with exposed die should be reserved exclusively for those who can accurately assess the risk, or make a living from such things. Such a procedure is never suitable for the masses, especially since you also lose the manufacturer’s warranty.

The integrated voltage converters of the Skylake-X

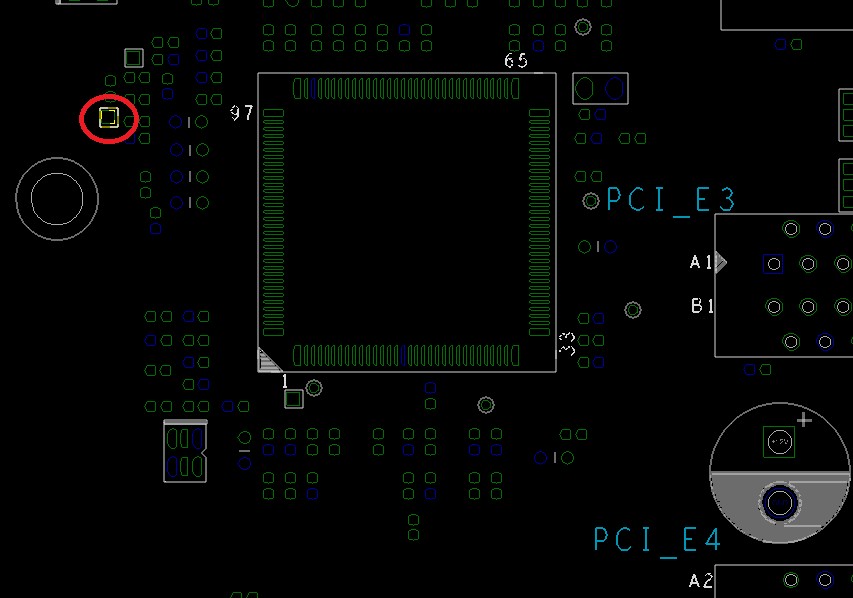

Abolished after Haswell, the integrated voltage regulators FIVR (Fully Integrated Voltage Regulators) in the Skylake-X now celebrate their not entirely unproblematic rebirth as IVR (Integrated Voltage Regulators). But what is actually behind this? The external voltage converters of the motherboard don’t only supply the Vcore at the measuring point (picture below) like in Kaby Lake-X, but first a kind of intermediate voltage Vccin as input for the IVR. This voltage can be between 1.6 volts and a maximum of 2.55 volts.

Incidentally, it was exactly this hermaphroditic status that led to many a CPU death in the run-up to the launch, when the BIOS was not reset properly when switching from Syklake-X with its minimum 1.8 volts to Kaby Lake-X and the then present, much too high Vcore, but simply played CPU out, CPU in. That’s just an anecdote on the side.

Based on this already very strongly lowered voltage, for whose generation the main load of the voltage conversion in the total sum lies on the external converters, internally in the CPU the voltage for the processor cores Vcore, as well as the partial voltages for the Lowest Level Caches, Ring Interface, PLL, Vccio (IO), Vccsa (System Agents) and Vcc33 (PIROM) are generated. As already mentioned, this output voltage Vccin of the MBVR (voltage converter of the mainboard) is controlled by the CPU via SVID bus (Serial Voltage ID). We already wrote that the used PWM controller IR35201 supports VR13.0. This VID-based voltage can best be compared with the load line of the Vcc of older CPUs.

Maximum values of the Skylake-X and extreme overclockings

Although Intel specifies the CPU’s TDP with only 140 watts, the maximum currentfor Vccin Icc_max has been quantified to a whopping 190 amps (2ms maximum) and the maximum permissible limit for Pmax Package has been set to an insane 297 watts. Own tests with much higher values already led to an emergency shutdown of the motherboard at 365 watts.

Leaflet #4

Power consumption for Vccin of more than 300 watts has nothing to do with a sensible overclocking, because the CPU is already loaded beyond its specifications. For stable overclocking in long-term use, we would rather consider permanent maximum values of up to 250 watts to be more realistic, which is still a lot.However, if you want to be fair, you would also have to subtract the loss of the IVR again for a direct comparison of the power consumption values of different CPUs with Skylake-X. These can also be in the double-digit range when the Pmax package is fully utilized.

Interim conclusion

In order to be able to fairly assess the CPU and motherboard, as well as the resulting temperatures in the next chapters, we should assume a permanent maximum power at the package of up to approx. 250 watts (the peaks can also be a bit higher for a short time). Values of more than 300 watts are out of the specifications and thus not the subject of our considerations from now on. If you want to boost your expensive CPU, please do so. Everyone is free to do so. But he will at least know the reasons from now on, because it will definitely catch up with him – sooner or later.

1 Antwort

Kommentar

Lade neue Kommentare

Urgestein

Alle Kommentare lesen unter igor´sLAB Community →