Attention allergy sufferers, the following text may contain traces of lead and sarcasm! Once upon a time, in a country called China, engineers and economists asked the eternal question, “Should our solder be leaded or lead-free?” You might say that this was a question of almost Shakespearean proportions: “To solder or not to solder, that is the question here.” So the lead thing… That wonderful heavy metal celebrated for its melting properties and for giving us so many terrific water poisonings in the past. And now that we live in an age where we are being asked to be more environmentally friendly and health conscious for a reason, one may ask, “Why the hell are Chinese companies still secretly using lead-based solder?” We’ll see in a moment that they do so in isolated instances.

And if we look back: First, there was traditional leaded solder. People loved it because of its smooth melting properties and how it felt, almost like spreading soft butter on freshly baked bread. But as with anything that seems too good to be true, leaded solder had its downsides. Basically, it wasn’t so good for Mother Earth. Nor for the health of people, animals, and basically everything that breathes. So that includes you and me.

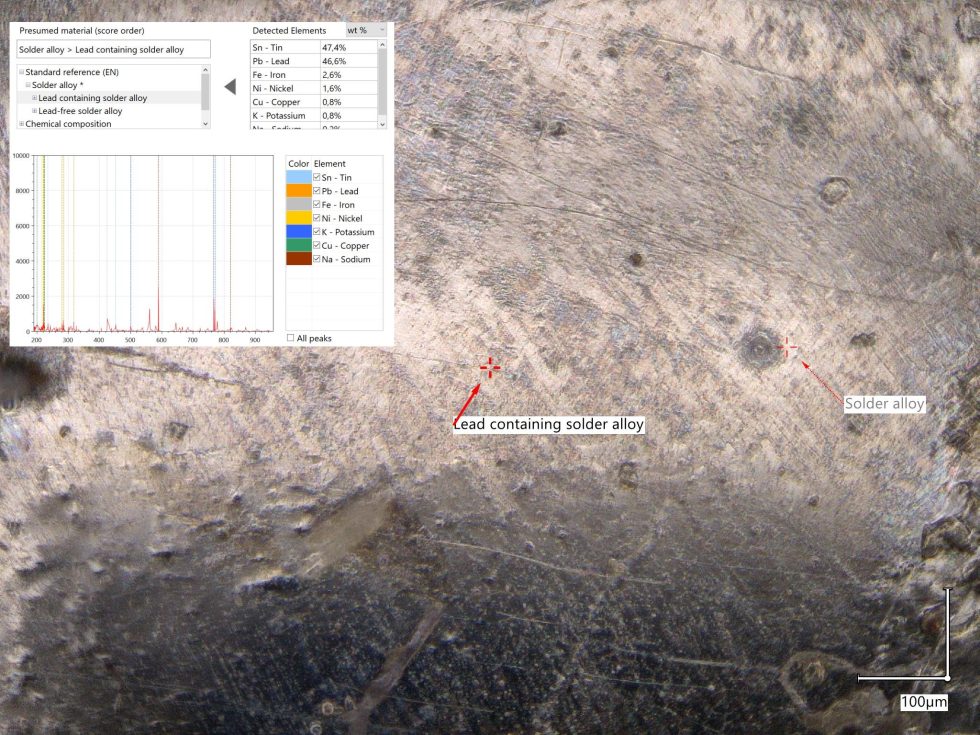

And anyway, why bother with this new fancy lead-free solder that requires more effort when you can just stick to good old lead solder and earn more that way, too? It’s like switching from an old Nokia phone to a smartphone. Expensive and (almost) no one needs it. And the ROHS (Restriction of Hazardous Substances) directive? This little environmental standard that tells us not to use toxic substances? Oh, that’s only for countries that can afford such expensive “environmental regulations”. Lead may be toxic, but it’s also cheap, effective and so shiny! And to hide this solder of doom from the evil inspectors, the good Lord invented glue and the devil immediately made cheap plug-in power supplies out of it (see above). The included solder joints then look like the one below:

And why all the fuss now? Working with lead-free solder requires a higher temperature and more precision. And who has time for that much perfection when you can just use the tried and true method? It’s like trying to eat with chopsticks when you could just use a spoon. There’s a bit of a catch, though: the lead-free solder is a little bitchy. It doesn’t always want to melt the way you wanted it to, and sometimes it felt like trying to get a rebellious teenager to clean up his room.

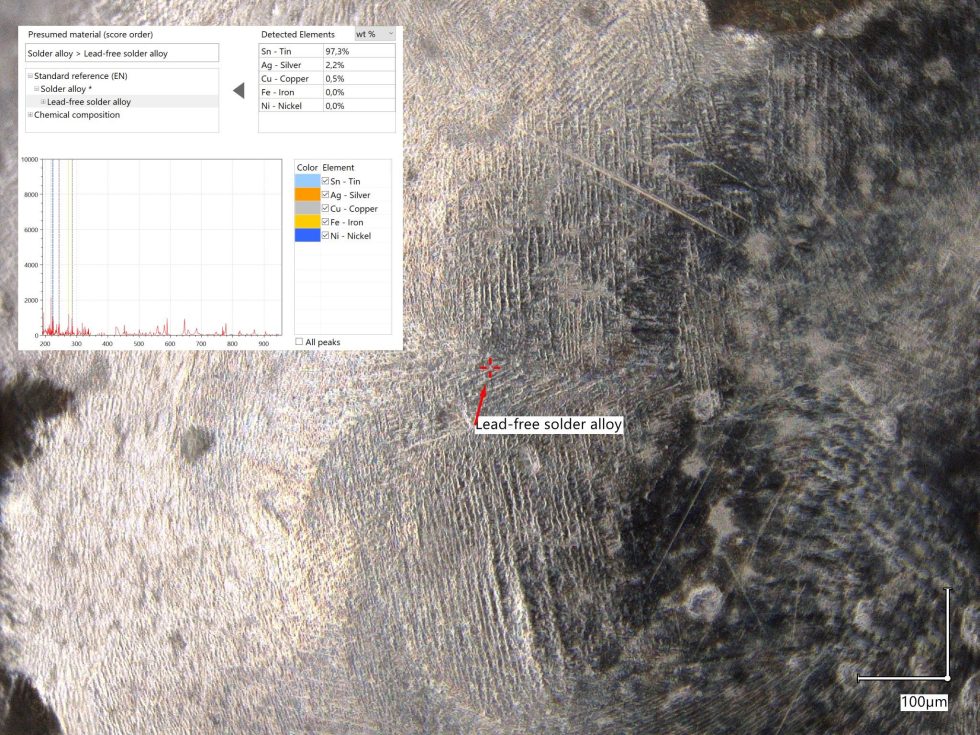

Or do you still remember the notebooks that spit out their GeForce graphics chips one after the other? Malicious tongues still claim that it was a normal rejection reaction of a battered computing device. But if you know solder and temperature, a durable solder joint is no longer witchcraft. It’s just more time-consuming and more expensive. How something like this looks in lickable and vegan, you can see here:

And what have we learned? Where there is no plaintiff, there is no judge. In this sense I wish you a healthy, lead-free weekend. Because Confucius already said quite right: “Don’t lick plug-in power supplies!”

186 Antworten

Kommentar

Lade neue Kommentare

Urgestein

Urgestein

Urgestein

Urgestein

Urgestein

1

1

Urgestein

Urgestein

Urgestein

Urgestein

Urgestein

1

Urgestein

Urgestein

Veteran

Urgestein

Urgestein

1

Alle Kommentare lesen unter igor´sLAB Community →