The test setup: tricky but functional

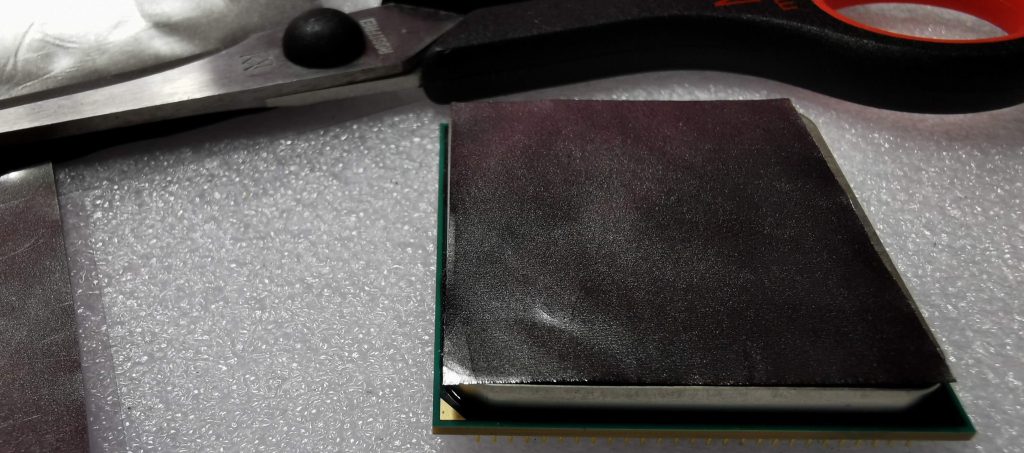

In order to create an imprint at the highest points that stand upwards, I have therefore blackened a thin metal foil with soot. Normal carbon paper is unfortunately too thinly coated and therefore excretes. I put this slide with the clean back down on the heatspreader of the CPU. Then comes the edition in the form of a thin piece of paper. Here I used normal, white 80 g paper, which I had slightly roughened on the support sides with 1000 fine-grained paper.

Then follows the simulated radiator floor, from which I had the CNC mill several very thick plexiglass floors, which then also fit on each base at the end. These plexiglass floors are absolutely flat, and due to their thickness of 12 mm, they are absolutely torsion-stiff and therefore lie perfectly on. I always fixed the whole thing nicely diagonally over cross in small increments with a good torque screwdriver, which I had set to 0.45 Nm. We are talking about the results obtained in this way in the form of the heatspreader impressions.

The slightly rough paper surface absorbs the pressed soot particles better and, above all, holds them tightly, otherwise you could easily smear or blow away everything. Especially when screwing on and on the plate there is always the risk of (if only slight) slipping. Unfortunately, this is a little handmade with the soot and thus also fluffy, which explains the slightly coarser sprinkles in the pictures. But you can still see very well where the Casus Knacktus lies with the respective CPU.

The Truth: Heatspreader Impressions of the 3 CPUs

So, now it's getting serious. Let's start with Intel and the big Core i9-9980XE. We see very nicely that all four corners are facing upwards, while the long itineraries are more flat except for one (left). But also in the middle, where the Die sits, there is still a slight curvature, the height of which is not quite as clear as that of the corners. I wouldn't have expected that, but I could also reproduce with a Core i7-7920X. Learned something again.

The Core i9-9900K shows similar symptoms at two corners, but is rather flat on the opposite side, which explains the large footprint. If these two high corners did not disturb, the radiator floor would really lie flat and the entire surface would be dark, where it is bright, the pressure is significantly lower. The few black crumbs we can neglect in the picture, here had certainly replaced soot.

The AMD Ryzen 9 3900X would need a different therapy, because this with the convex curvature is pretty much exactly consistent with what I had already shown on the scheme of the previous page. However, since the chiplets (in this case on the right) are on the side, the cooling with not optimally filling thermal paste would be rather bad. It is striking, however, that corners and edges do not matter here. But what is really better, we have to clarify right away.

Let's consider a Ryzen 9 3900X after the BurnIn with a phase change material, which is first applied as an elastic pad and then above approx. 55° plastically cured. The fragmented areas were created during weight loss, i.e. negligible. The layer thickness of approx. 0.2 mm before the BurnIn and from less than 0.1 mm after the BurnIn, the unevennesss compensate well. But what you can see perfectly is the heat distribution. We can see that both chiplets are on the right and that the upper chiplet has left more traces of heat than the lower chiplet (but only 4 cores were active).

Own experiments with extremely thin thin graphite films have also shown that these multi-use films can perform reasonably well on Intel CPUs, but especially on the third-generation Ryzens must leave distinct feathers, because the cavities have to be clearly springed up, because the cavities have to be cannot be filled in perfectly.

Conclusion for the application and the amount of thermal paste

Even if the area of the Ryzen CPUs is roughly the area of a CPU for the socket 2066 from Intel, one would actually have to proceed differently with the paste. If you use a very liquid paste ("flood chinaut"), then you would be able to handle the blob safely with both CPUs. However, this is such a problem with the quantity. Too little would lead to a very uneven layer, too much to a partially far too thick layer. I always have to smile internally at those who buy high-priced thermal paste with more than 10 W/mK, but who then put on it so thickly that a thin layer would have an industrial paste with only 3 W/mK at the end even the lower thermal resistance. I explained and even calculated why this is the case in the article that has already been linked.

As a conclusion, I use only relatively liquid paste and a very elastic spatula with a clean edge for all Ryzen CPUs. Then pull the blob from the middle with the spatula still outside to the edges and it is best to avoid then swiping from edge to edge over the middle. In the middle you can even keep the paste so thin that it is almost translucent, it will still be loose.

The large Core i9 can tolerate both, blob and spatula method. The spatula also gets you there quite well, if you stroke from side to side throughout. The Die sits in the middle and cavities at the edges are rather less important. But here too: less is often more! The CPUs for the socket 1151 are the most uncritical, especially since the area is also much smaller. Blobs and be happy. If you like the viscous paste, you should warm it up (approx. 50 + 60 degrees) and then pass with the spatula.

And what is better? This cannot even be answered unambiguously, as the unevennesscanevenly deviate from CPU to CPU and can be very different. The easiest way to handle is the small heatspreader of the Socket 1151 CPUs, which is also the smallest. Otherwise, it's more of a draw with slight benefits for Intel. The rest sinks anyway in the almost always too thickapplied thermal paste of the Kleckser fraction.

Kommentieren