No, I’m not going to test the cooling performance of radiators for PC cooling today, but I am going to take a closer look at the first six manufacturers and their current models to see whether they really do contain exactly what the marketing advertises and the customer buys in good faith in some cases. In the first part, I obtained radiators from six well-known manufacturers from the retail trade, completely dismantled them and analyzed them in detail. The reasons for today’s test are no secret, as I am often contacted when it comes to clogged water cooling components or unexplained corrosion. Something like this triggers me just as much as my beloved 12VHPWR and ultimately provokes the necessary curiosity to go to such time and financial expense.

Today we start (in alphabetical order) with frequently purchased products from Alphacool, Aqua Computer, Bykski, EK Water Blocks, Hardware Labs and Watercool, whereby I have already purchased further products anonymously from Amazon and others for a follow-up. In addition to Corsair and the new radiators from Thermaltake, there will also be typical Chinese products for a small price, where often enough a single OEM is behind many brands, so that I can even test these parts as examples. Regardless of whether these products are sold as Magicool at Caseking or Richer-R, Diyeeni or Tonysa at Amazon, AliExpress & Co, it’s always the same manufacturer, only the packaging and prices change from 8 to 30 euros. But that will come in the next parts.

Normally you have to believe what the supplier sells you and what their marketing advertises. And so today it’s not just about the details, but also the credibility of the specifications, whereby I can already spoil the fact that I didn’t just catch one manufacturer lying and another even wrote more in the specs than all the others. I also adapted part of the RoHS test by looking for lead in the solder. There will also be something to write about this, because unfortunately I found what I was looking for.

| Manufacturer | Model (size) |

| Alphacool | NexXxoS ST30 Full Copper X-Flow 120mm |

| Aqua Computer | airplex radical 2/120, aluminum fins |

| Bykski | CR-RD120RC-TN-V2, 120mm Radiator D30 V2 Full Copper |

| EKWB | Quantum Surface P120M – Black |

| Hardware Labs | Black Ice Nemesis GTS – 120 XFlow |

| Watercool | HEATKILLER RAD 120-S Black |

For reasons of handiness and also sustainability, because I have to separate the radiators and thus render them unusable, I test the smallest models that can be obtained quickly, i.e. the 120 models. This is not a problem, because it is not the length that is decisive, but the material itself. After all, today it’s not about the cooling capacity, but the components. I’m going to do this and other tests because no one has ever done it in this depth and published it. And perhaps it will also answer a few questions on its own as to why some things work differently than planned and hoped for in your own PC practice during continuous operation.

Test equipment for the material tests

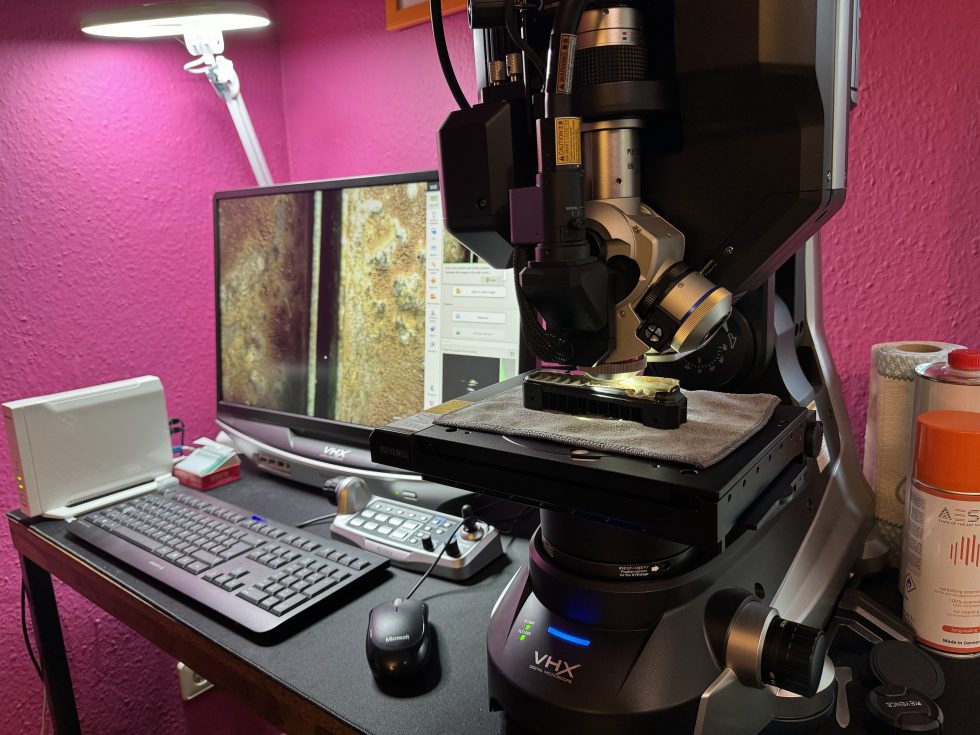

The material testing and measurement of the radiators is carried out by my Keyence VHX 7000 with EA-300, which has now been fully upgraded and enables both precise measurements and quite accurate mass determinations of the chemical elements. But how does it actually work? The laser-induced breakdown spectroscopy (LIBS) I used for this article is a type of atomic emission spectroscopy in which a pulsed laser is directed at a sample in order to vaporize a small part of it and thus generate a plasma.

The emitted radiation from this plasma is then analyzed to determine the elemental composition of the sample. LIBS has many advantages over other analytical techniques. Since only a tiny amount of the sample is needed for analysis, the damage to the sample is minimal. The real damage is caused in today’s article by my rather coarse cutting and separating tools. This still quite new laser technique generally requires no special preparation of the samples for material analysis. Even solids, liquids and gases can be analyzed directly.

LIBS can detect multiple elements simultaneously in a sample and can be used for a variety of samples, including biological, metallic, mineral and other materials. And you get true real-time analysis, which is a huge time saver. As LIBS generally requires no consumables or hazardous reagents, it is also a relatively safe technique that does not require a vacuum as with SEM EDX. As with any analytical technique, there are of course certain limitations and challenges with LIBS, but in many of my applications, especially where speed, versatility and minimally invasive sampling are an advantage, it offers distinct advantages.

Foreword on accuracy and proportions

I would first like to point out that the results of the percentages in the overviews and tables have been intentionally rounded to full percentages, as it happens often enough that production variations can occur even within the presumably same material. Investigations in the parts-per-thousand range are nice, but today they are not useful when it comes to reliable evaluation and not trace elements. I therefore only deliberately searched for lead in the percentage range, although the RoHS states that it may be less than 500 mg per kilogram of solder. However, I am not the testing institute and will only denounce those who really deliberately use lead and not those whose products only contain minimal traces of impurities. Although this is also unpleasant, it completely misses the point. Anything above one percent is no longer a coincidence, but really intentional. And I will find that.

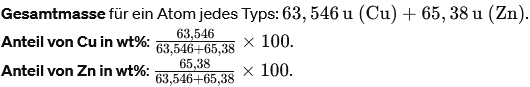

Furthermore, it is certainly debatable whether the percentage of an element in the sample is better expressed in at% or wt%, because it is almost negligible for our self-imposed accuracy range. For example, to illustrate the difference between zinc (Zn) and copper (Cu) in terms of weight percent (wt%) and atomic percent (at%), let us consider a hypothetical example in which an alloy (brass) consists of zinc and copper.

The atomic weight of copper (Cu) is about 63.546 u and that of zinc (Zn) is about 65.38 u. For ease of comparison, let’s take brass that consists of equal parts zinc and copper in terms of atomic number, so 50 at% Zn and 50 at% Cu (which is how I usually measure, since I’m not a metallurgist). To calculate the difference between at% and wt% for Zn and Cu, you determine the molar mass of the alloy and take the average atomic mass of both elements as the basis for the calculation. The weight percentage (wt%) of copper (Cu) is about 49.29% and that of zinc (Zn) about 50.71%.

Despite the assumption of equal atomic percentages (50 at% for both elements), the different atomic weights of zinc and copper lead to a slight difference in the weight percentages. Zinc, which has a slightly higher atomic weight than copper, takes up a slightly larger proportion of the total weight of the alloy (50.71% wt% compared to 49.29% wt% for copper). This example illustrates how at% and wt% can reflect different aspects of an alloy’s composition. Although the atomic percentages are the same, the different atomic weights result in different weight percentages. These differences are important to understand as they can affect the physical properties and processing of the alloy.

interestingly, some manufacturers refer to the atomic weight, while others use the weight percentages as a benchmark, but without making specific reference to them. However, as I deliberately do not compare absolute masses, this can almost be neglected in the case of copper and zinc. The difference between at% and wt% in the EA-300 result overviews for these two elements is always in the decimal range, so that I always use at% in the images (with a few exceptions where I wanted to calculate further). The proportional atomic weight at% is therefore completely sufficient and meaningful enough for a ratio, but the metallurgical weight ratio is still listed in the comparison tables. So please do not be confused if the figures in the graph and table differ in nuances! Normally you would also write 99.9% copper, because you always have to allow for tolerances, but by rounding up I simply use 100%, which is less confusing.

But it can also be much larger and coarser when it comes to dividing up more trivial things. This includes the tools for cutting and exposing the assemblies, from a Dremel to a pendulum action saw to a large chop saw for the very long cuts right through the radiators. I’d better spare you the details of these pictures from the workshop, because it really was a fine shaft festival. Where there is sawing and cutting, there are chips and in the case of the radiator from Aqua Computer with the polyacetal (Delrin) it was a real mess, but all in good time. Nevertheless, it was worth it, I can spoil that in advance. And I also had to clean up afterwards.

The big Radiator Material Test: Even more lead, a popular hiding place and 2.5 bright spots | Part 2

Alphacool NexXxoS ST30 Full Copper X-Flow 120mm (14228)

| vorbestellbar | 39,58 €*Stand: 27.07.24 03:16 |

Aqua Computer airplex radical 2/120, Aluminium-Lamellen (33701)

| Lagernd im Außenlager, Lieferung 2-3 WerktageStand: 27.07.24 03:24 | 69,45 €*Stand: 27.07.24 03:26 |

| lagernd: 1 | 69,46 €*Stand: 27.07.24 03:16 |

| Lagernd | 79,90 €*Stand: 27.07.24 02:47 |

Bykski RC Series Thin Radiator 120 (CR-RD120RC-TN-V2)

EK Water Blocks Quantum Line EK-Quantum Surface P P120M Black (3831109838334)

| Lager Lieferant: vorrätig, 3-5 Werktage | 59,39 €*Stand: 27.07.24 03:05 |

| Lagernd | 62,90 €*Stand: 27.07.24 02:47 |

| Alsdorf: bei Vorbestellung in ca. 24h - 48h lagerndVersandlager: bei Vorbestellung in ca. 24h - 48h lagerndStand: 26.07.24 23:45 | 64,90 €*Stand: 26.07.24 23:47 |

Hardware Labs Black Ice GT Stealth 120 XFlow

Watercool Heatkiller RAD 120-S Black (24100)

| Lagernd | 44,90 €*Stand: 27.07.24 02:47 |

| siehe Shop | 49,95 €*Stand: 27.07.24 00:00 |

| 4-6 Werktage | 52,43 €*Stand: 27.07.24 03:05 |

- 1 - Intro, Samples and Equipment

- 2 - Alphacool NexXxoS ST30 Full Copper X-Flow 120mm

- 3 - Aqua Computer airplex radical 2/120, Alu-Lamellen

- 4 - Bykski CR-RD120RC-TN-V2, D30 V2 Full Copper

- 5 - EKWB Quantum Surface P120M - Black

- 6 - Hardware Labs Black Ice Nemesis GTS - 120 XFlow

- 7 - Watercool HEATKILLER RAD 120-S Black

- 8 - Summary and Conclusion

411 Antworten

Kommentar

Lade neue Kommentare

Moderator

Urgestein

Urgestein

1

Veteran

1

Urgestein

Urgestein

Urgestein

Mitglied

1

Urgestein

Urgestein

Urgestein

Urgestein

Veteran

1

Veteran

1

Alle Kommentare lesen unter igor´sLAB Community →