Capacitor question

Now, after so many appearances, let us move into the interior and consider the Gretchen question: Which condesators should or should be and where are many misunderstandings and errors? And with that we would have got the curve from the GPU, over the PCB, the connections and the supply lines to the capacitors quite well.

Intermediate question: What are the effects of polymer capacitors?

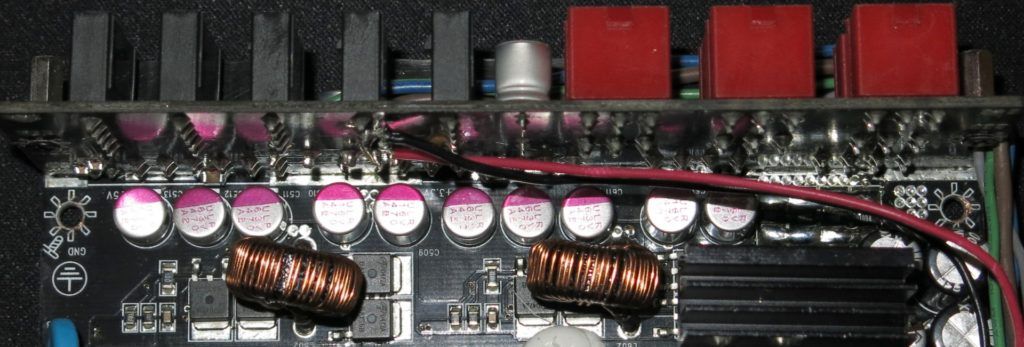

In a rather on a whim, two simpler power supplies with and without cable management, which were actually quite identical except for the KM board, as well as a rather nasty HIS R9 290X IceQ, which generates a lot of spikes, ( Power consumption see graphic on page 3), we came to a surprising result: I could see that the additional polymer capacitors used in the modular power supply were able to cushion the tips quite neatly on the input side, if they are really well placed. On the one hand, the solids are much more nimble than the electrolytic capacitors and on the other hand, the required capacity can be much lower due to the short duration of the extreme peaks to still have an effect.

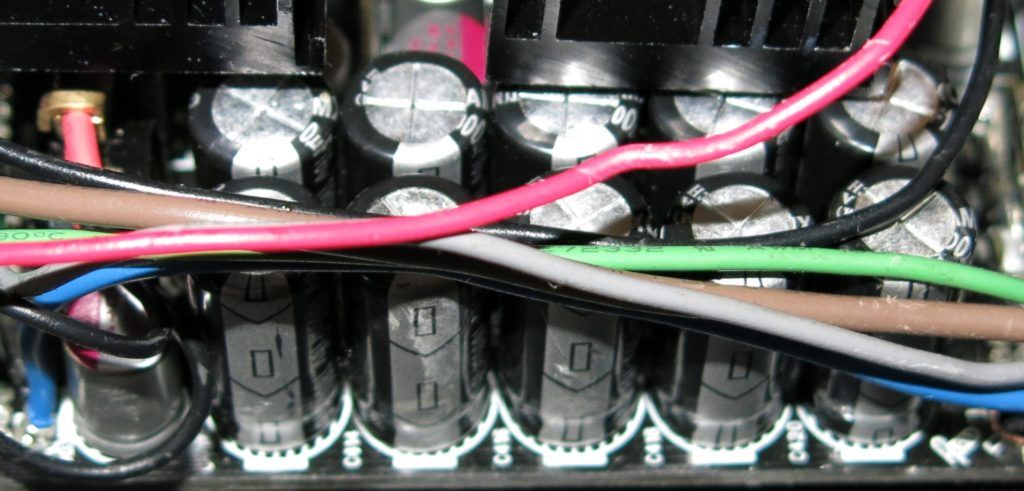

This should certainly have a positive effect on the durability of the actual secondary capacitors (pictured below), even if it is usually only an indirect consequence. For many power supplies, these polymer capacitors are primarily used to prevent, for example, the interactions between the main transformer and the vertically standing board occurring during the separation of the main and cable management boards.

However, this side effect, which we observe and which are very useful, is always welcome, even if it was certainly not considered in every power supply. You can also see one of the typical mixed calculations when it comes to optimizing costs: medium-sized SamXon on the secondary side.

Which would also make the arc to the actual electrolytic capacitor quite elegantly, about which there is still far too much ambiguity.

Low ESR, Low Impedance and Ripple

First of all, let us take stock. So what does a good secondary condesator have to be able to do at least? It is intended to ensure that the power supply can continuously deliver high currents and also guarantee that load fluctuations can be intercepted. So far, so theoretically. But Elko (electrolytic capacitor) is not the same as Elko. And it is precisely at this point that it becomes interesting when we talk about the quality of the data sheet and the usefulness of the choice of capacitor, which do not necessarily have to be covered!

Let's go one step further and ask ourselves what such an Elko – also in terms of our wild graphics cards – should be able to do most well now? For reasons of durability, it must first have as little internal loss resistance as possible (ESR = Equivalent Series Resistance). This is why these so-called low-ESR versions are often found on the output side in power supplies or on motherboards in the area of VRM.

However, our measurements of power consumption, where the intervals of the load changes sporadically follow each other even faster than the switching power supply can recharge the capacitors, let us think a little bit here. Many manufacturers are now switching – certainly not without good reason – to very special low-impedance capacitors, where low internal resistance at high frequencies is at stake, which standard elcos do not offer in such perfection. So much for expediency. But a little more later on.

We reckon a little and wonder

As we know, capacitors do not flow direct currents, but so-called rippel currents. ripple current), which in the end is nothing more than the pulsating direct current that we have already mentioned. Now let's take a data sheet from Teapo and compare which capacitor might be the most convenient. In order to guarantee a sufficiently low residual ripple even with a very slow switching power supply, at currents up to 20A (in relation to the mentioned R9 290X) easily 3300 F per rail, at 30A it should then be 4700 F and everything above it is parallel connection of the Elkos.

The now popular Teapo SY (Low Impedance) with 3300 F as a 16V model has an impedance of 0.02 ohms at 100 KHz. At 20 amps, inkusive self-discharge swells approx. 0.25 volts, which corresponds to a ripple of about 2.1 percent and results in a power dissipation of about eight watts. According to the data sheet, 2.88 amps (rms) are planned at 5000 hours. So this fits perfectly, because you will not reach such maximum values in life.

A Ky-series Nippon Chemi-Con has exactly the same data, but promises double the durability of 10,000 hours at the maximum ripple currents. At first this reads like a double good Elko, but since this load is not even reached in the beginning with good models, the hour indication is also rather theoretical – because before that usually the fan or something else breaks.

Even the CapXon, demonized as a cheap home and "bad cap", can still achieve good results – if you are willing to pay for execution and quality class. For example, a CapXon GF (Low Impedance) with 3300 F as a 16V model even has an impedance of only 0.018 ohms at 100 KHz and creates a very decent 3.49 amps at 5,000 hours. Of course, it also goes in the direction of the cheapest rail. The Jun Fu WX with 3300 F 16V still manages 0.022 ohms, but falls back to 2.1 amps for the ripple current. And then there are the really bad models, about which we better write nothing more.

Where are or/or were the possible quality problems?

The electrolytes used must be very conductive, especially for low-ESR and low-impedance Elkos, so that the ripple currents do not cause any damage. In order to increase the conductivity, various solvents and additives are used, one of which is mostly water. The mixed water automatically increases the number of free ions, which naturally leads to a much better conductivity of the electrolyte. Without wanting to bore the poor reader with too much chemistry: even water contaminated in traces attacks aluminium. In an exothermic reaction, the aluminium then corrodes and a hydroxide (AL(OH)3) and a gas are produced, which then leads to an increase in pressure in the capacitor housing.

In the picture we can see the bumps in the cup and the set break points in the cap, which should open when too much pressure is applied. If they do, after a hissing one has a fine sourness on the board, which also likes to lead to shortenings. Or it doesn't open, then it pops and the sow is more bubbly.

Manufacturers should now have full control of the aggressiveness of the water towards aluminium. However, especially in the early days, many manufacturers had problems in production and technology, so that not a few Elkos became a ticking time bomb. Many prejudices also stem from this period, which are no longer justified, at least in large parts, today. The so-called bad caps list is now completely outdated in terms of content, as the finishers often still produce the same model series, but the products are no longer the same.

What should I buy now?

The question is not so easy to answer because details matter.

A suitably selected secondary elco of a Taiwanese or Chinese manufacturer may be quite equivalent or even better if the power supply manufacturer uses a correspondingly high quality class which also excludes greater manufacturing tolerances, than a simpler Nippon product, which has poorer technical specifications but is supposed to score points over the name of the manufacturer in return.

So you now get exactly the thing you're willing to pay for from almost every manufacturer. No more, but almost always no less. This does not make the assessment any easier and once again the network distributors are called upon not only to celebrate company labels with more distance and objectivity, but also to take a look at the installed quality classes. As a graphics card tester, you like to say: Not my construction site, although you shouldn't let the interactions out of sight.

- 1 - Einführung und Projektvorhaben

- 2 - Grafikkarten und die Tricks mit der Leistungsaufnahme

- 3 - Leistungsaufnahme-Messung: Benötigte Technik

- 4 - Leistungsaufnahme-Messung: Praktische Umsetzung

- 5 - Radeon R9 295X als Netzteil-Killer? Myth busted!

- 6 - AWG was? Kabelsalat und Gegrilltes vom Chefkoch

- 7 - Schalten und Walten - Wir schauen ins Netzteil

- 8 - Bad caps, good caps? Die Mär vom japanischen Drachen.

- 9 - Zusammenfassung und Fazit

Kommentieren