The second water block I tested was the Hydro Series XG7 RGB, a product from Corsair for NVIDIA’s large Ampere cards. Interestingly, the interest of most manufacturers in detailed tests is now rather restrained, because especially the comparison series of the GeForce RTX 2080 Ti has shown very clearly that RGB and bling-bling do not help with cooling and instead many a supposed top dog has unexpected cooling deficits. Then the supposedly free PR through such a test quickly turns into a small slap.

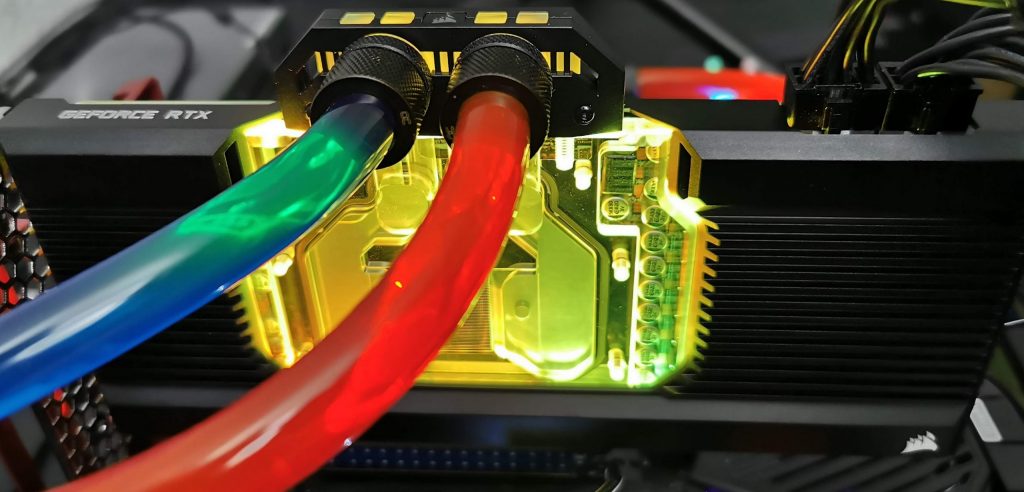

But back to the Hydro Series XG7 RGB. After the terminal problem with the RTX 2080 Ti, Corsair has at least recognized this problem and also elegantly solved it, so much in advance, because the water splashing out is all no longer an issue, even at over 200 l/h. Visually, the familiar design has been retained, which is not a bad thing. What else? Let’s get this thing unpacked first! By the way, in the picture we see the block for the reference design and the one for the Founders Edition, which are fundamentally different. Here you really have to be careful what exactly you order.

Scope of delivery and unboxing

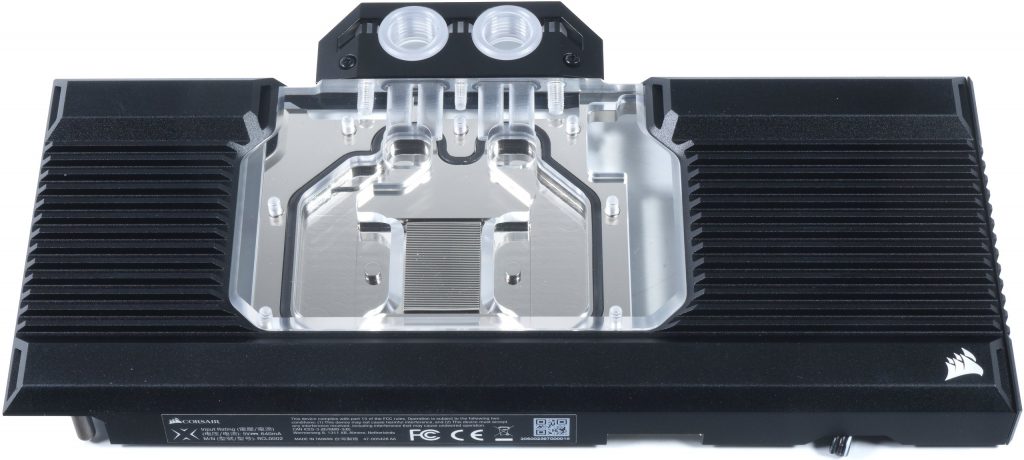

Compared to its predecessors, the manufacturer has fundamentally revised the cooler’s interior. This can also be seen in the accessories, because besides the completely pre-assembled block with the firmly screwed terminal, the already applied thermal paste, the applied 1 mm thermal pads and the backplate, you also get a few screws, 2 plugs, a small tool to tighten these plugs, an aRGB adapter and the small manual. That’s all you need.

Which brings us finally to the water block. We already know the blackened aluminum cover with the familiar groove design and the PMMA insert above the cooling block. The terminal is completely new, made of acrylic and this time finally fixed with three screws. The missing screw in the middle had caused big problems with the block of the RTX 2080 Ti at the time. It’s finally history. But also here Corsair has let the memory bars flow into the design visually, and adapted the look to the Dominator products.

The aRGB stripes are embedded in the floor underneath the acrylic, the rest of the illumination is done by the plastic up to the terminal.

The threads are relatively cleanly cut and the first impression of a thoroughly accurate implementation is reinforced here as well. Accurate fit and clean edges, a neat surface and hardly visible tool marks are definitely no reason for any criticism, on the contrary. You can even praise that for once. But I have to write a few words about the copper block itself.

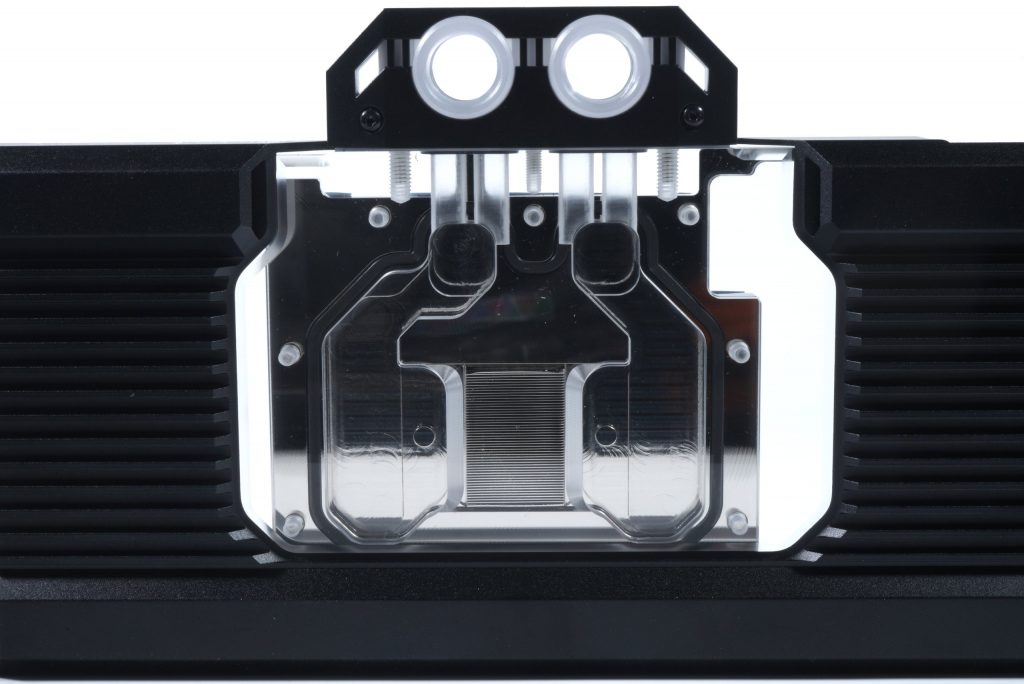

Let’s take a look at the cooling block from the front to follow the water circuit. In principle, one uses only one, even relatively small chamber here, which only actively covers the GPU and memory with the water flow. On the left is the intake, on the right is the exhaust, and both sides are connected in the middle with the recessed GPU block, whose cut fins also have cross channels. I swapped the inlet and outlet once out of sheer curiosity and the cooling result was the same. It’s almost symmetrical. The cooler doesn’t have as extreme a mitigating effect on flow as the Alphacool cooler we’ve already tested, but this (supposed) advantage is also based on a decent disadvantage, as we’ll see.

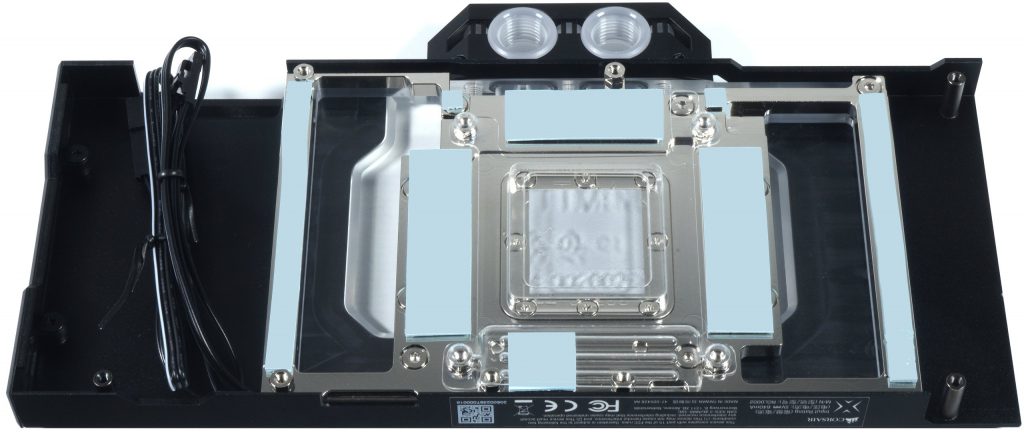

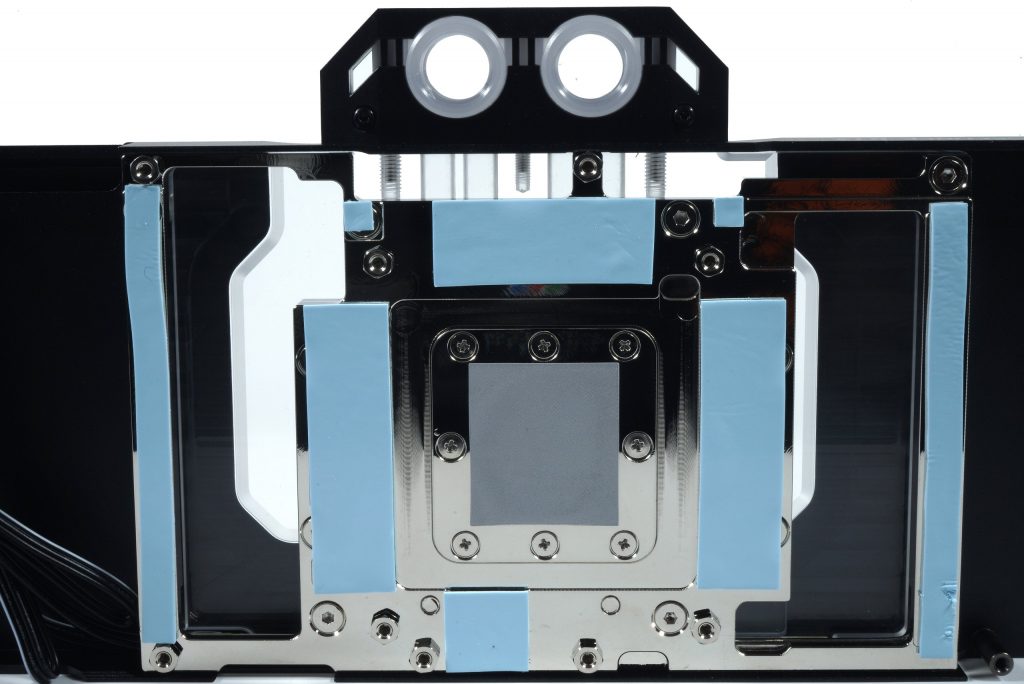

If we look at the cooling block from the rear, the trained eye will immediately see the deficiencies in the cooling of the voltage converters, which are located further out. Here the cut out copper is the only heat conductor up to the actively water cooled part of the block! You don’t have to be a prophet to estimate the temperatures of the voltage converters that Corsair so neglects. Because that’s more of a cooling frame than an actual cooling block. The reason is to be found in the so-called reference design, which leaves it up to the manufacturers to use flat SMD or tall cup capacitors. Now you can divide the block (like Alphacool) or take thicker copper or, like Corsair, simply make a cutout. This is unsightly, but it also works.

The reasons are relatively clear to see, because you simply save on the copper. In order not to have to work with split copper blocks or even with a thicker base material like Alphacool does, all so-called leave-out areas are simply cut out of the copper completely. Hence the large cutouts for the areas above the coils. This also simplifies production and shortens the production time enormously if material does not have to be removed precisely and over a large area in several layers.

In the middle we also see the block with the cooling fins as a separately inserted part. Since one needs clearly more height, the block this however by the small thickness hardly gives, one simply pieces the whole. This is simple and very effective, but also brings disadvantages. But more on that in a moment. The backplate is quite thin, but fits well into the overall picture. The already applied pads on the back are meant for double-sided assembly of the GeForce RTX 3090, but they are absolutely ineffective on an RTX 3080 due to lack of thickness, because they don’t allow contact to the PCB.

The cooling effect goes to zero with an RTX 3080, so I didn’t have to consider it in the measurements either. Who would like to improve here and should do this also in the area of the voltage transformers, ultra-soft 3 mm pads are needed. A word about the adapter, because you can use it to control the aRGB of any suitable motherboard that doesn’t have special Corsair headers.

Selection of the test card and general problems when using the GA102

The requirements are similar to Turing, although this time I settled on a 340-watt setup and a very specific GeForce RTX 3080 because it was nearly impossible to find a reference-design RTX 3090 specifically for these cooler tests, and you also need a card that’s right in the middle of the tolerance range for package heights. There will have to be an extra review on this in due course, though to be fair I’d like to wait for NVIDIA’s response first.

If you have cleaned the PCB as usual, you should first test it with the thermal pads applied to the cooler, but WITHOUT thermal paste, by putting it on and seeing if anything tilts or if there is not too much air between the PCB and the spacers. If the distance is larger than approx. 0.2 mm, then one gets a problem with the screwing, because it could bend the board excessively. For such a case I recommend spacers of about 0.1 to 0.2 mm thickness made of acrylic or impregnated hardboard.

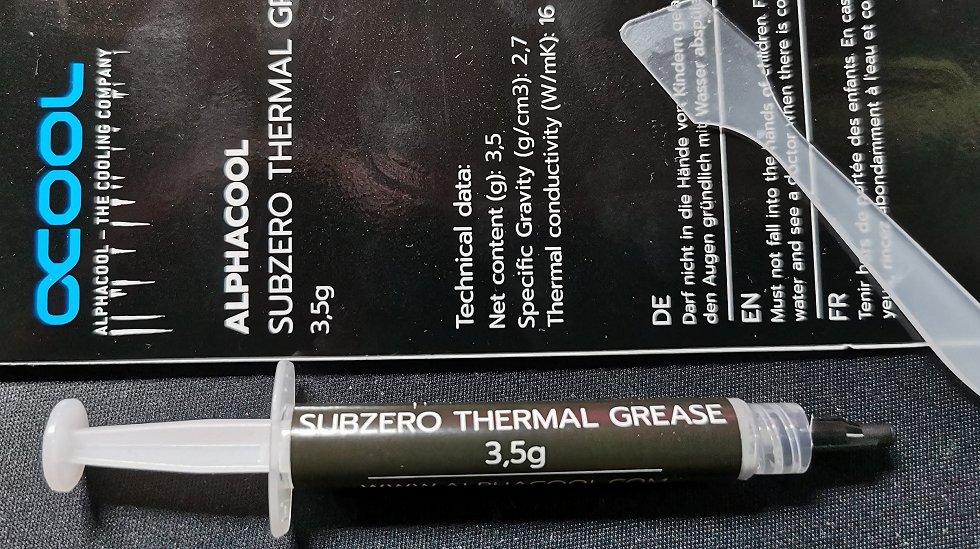

I also have to say something important about the thermal paste, because it is not that simple this time. Either you use a popular, very thin paste and risk a slow leakage of the paste due to the curvature of chip and package, or you better use an at least equivalent, but more viscous paste, which then stays where it is applied. For this reason I used Alphacool’s Subzero in my counter test, which also gave me another Kelvin less in the delta between water and GPU sensor.

Then you finally screw the whole thing together, connect the hoses and you’re done. The assembly of the already mouth-ready presented block is truly no witchcraft, so I will dispense with further details here. But the whole thing is beautifully colorful, that must be admitted without envy.

Kommentieren