In many basic articles I have already conveyed the theoretical basics and some background information on the correct use of infrared technology for years, without, however, going into more detail about the concrete application in my measurements. Five years ago, I then presented the current technology, although this article is still valid today.

Original article from 2016

However, we feel that it is quite necessary to explain the difference between methodical and pre-planned work and simply “keeping at it”. All too often, the results of infrared measurements are sold as incontrovertible facts that unfortunately have nothing to do with reality. It doesn’t matter whether you measure graphics cards, processors, mainboards or entire devices such as notebooks – the basics are always the same.

In the end, you can measure anything without knowing the most important theoretical basics – just not what you really need and actually want to measure. Therefore, after the presentation of our technique on the following pages, we also want to describe what can go wrong and what you as a reader should always pay attention to when classifying infrared measurement results from different sources when it comes to trust and plausibility.

Incidentally, we will later explain why we have dispensed with the use of convenient “handhelds” and instead use a camera that has been fixed in a stationary position and that can be optimally adapted to the respective measurement setups (distance, area to be covered) with real and high-quality interchangeable lenses. However, this type of use also requires more work and time to set up and calibrate accurately. Only this also benefits the readers – and that’s what it’s all about in the end.

But before we go into our concrete measurement methods and setups, we would first like to briefly introduce our Optris PI640 IR camera, which is probably less well known in this form (quite unjustifiably), although it is possible to make really reliable measurements if handled correctly. From a purely price point of view, it is actually a cheaper alternative compared to certain handhelds, with significantly more possibilities and ultimately also higher accuracy, even if it is mostly at home permanently installed in the industrial sector.

However, such devices not only involve extensive development and production processes, but also complex calibration and maintenance. Without regular calibration, even the best technology is of no use, because many things can change and age over the course of daily use. In addition, of course, everything should be on the technical Höchtstand, so that always new devices must be developed. This is the reason for our change from the previously used Optris PI450 to the Optris PI640, which gives us even more possibilities.

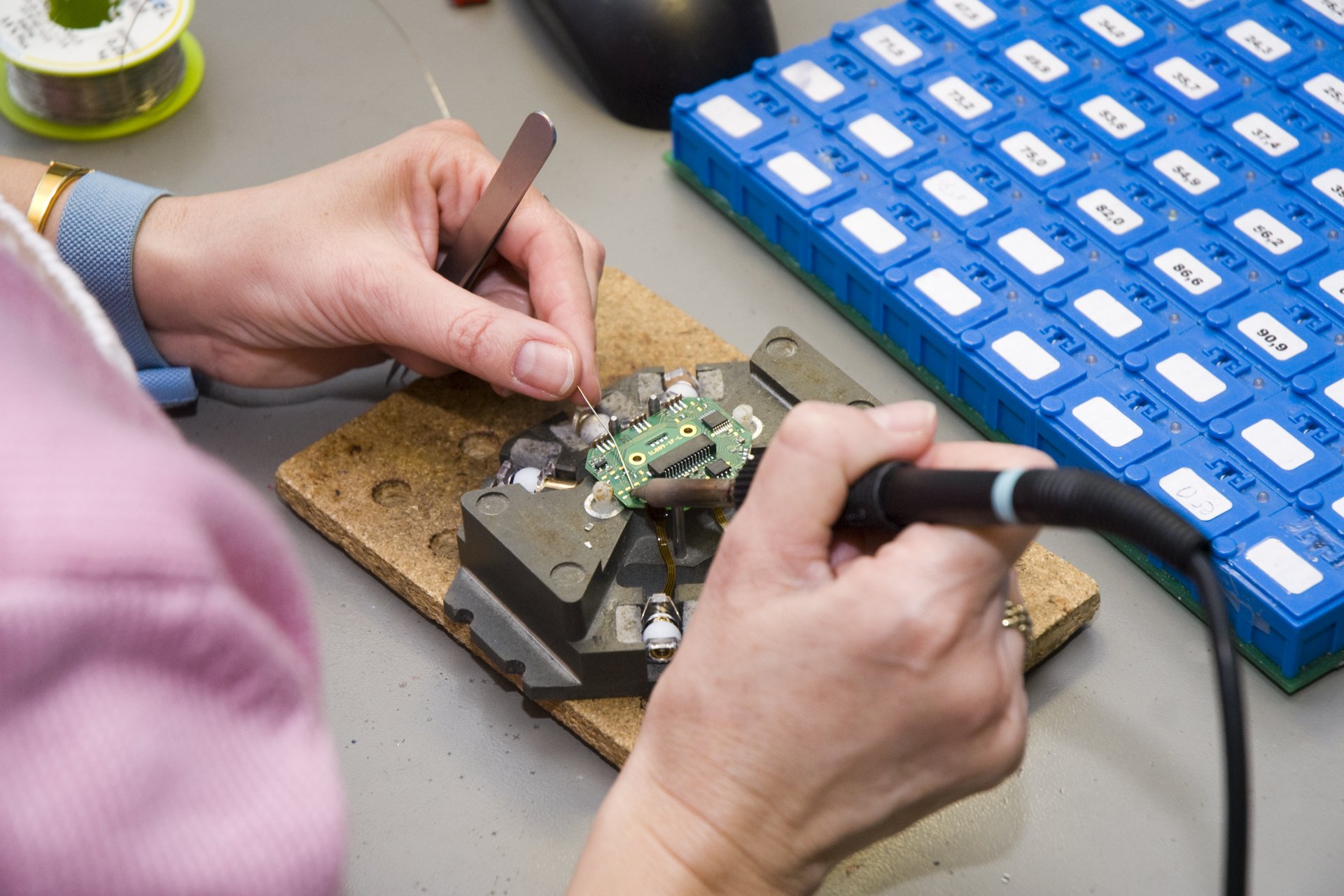

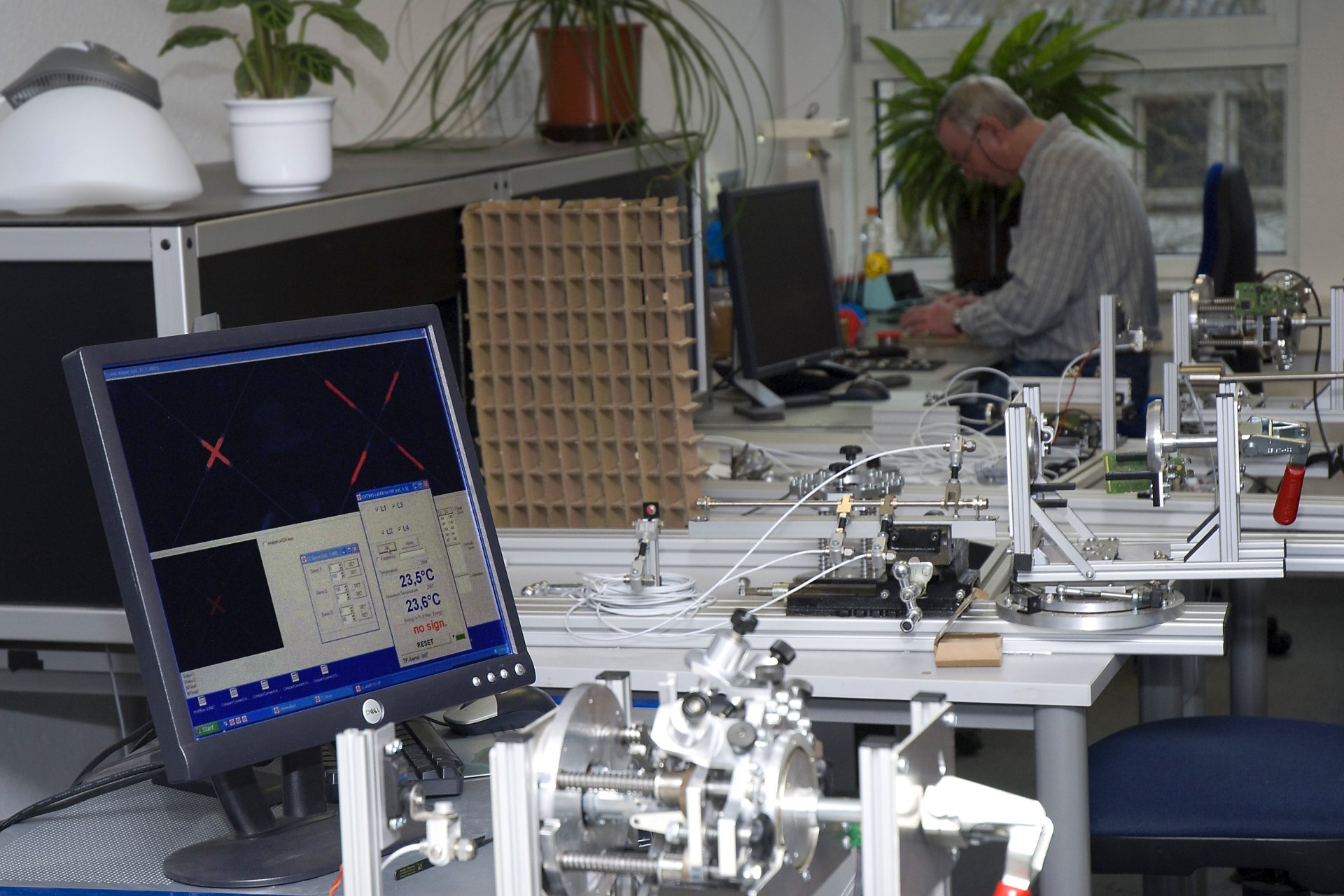

As an example, we have taken some photos of Optris’ development, production and service for the interested reader, but we ask for your understanding that we cannot publish certain internal and secret contents, no matter how interesting they may be.

|

Printed circuit board design |

Printed circuit board assembly (signal unit) |

|

Adjustment |

High temperature calibration |

Once again, a brief overview of the technical data before we go into more detail about our measurements:

| Technical data of the IR camera Optris PI 640 | |

|---|---|

| Detector: | FPA, uncooled (17 μm x 17 μm) |

| Optical resolution: | 640 x 480 Pixel |

| Spectral range: | 7.5 to 13 µm |

| Temperature ranges: |

-20°C to 100°C 0°C to 250°C 150°C to 900°C |

| Frame rate: | 32 Hz |

| Optics (FOV): | 33° x 25° FOV / f = 18.7 mm or 15° x 11° FOV / f = 41.5 mm or 60° x 45° FOV / f = 10.5 mm or 90° x 66° FOV / f = 7.3 mm |

| Thermal Sensitivity (NETD): | 75 mK |

| System Accuracy: | ± 2 °C or ± 2 |

| Interfaces: |

PC interface USB 2.0 Process interface (PIF): 0 to 10 volt input, digital input, 0 to 10 volt output |

| Housing (size / protection class / weight): |

4.6 x 5.6 x 9.0 cm IP 67 (NEMA4) 320 g incl. lens |

| Shock / Vibration: | 25G, IEC 68-2-29 / 2G, IEC 68-2-6 |

| Scope of delivery: |

USB camera with 1 lens |

The game is now on!

Kommentieren