Body and loudspeaker

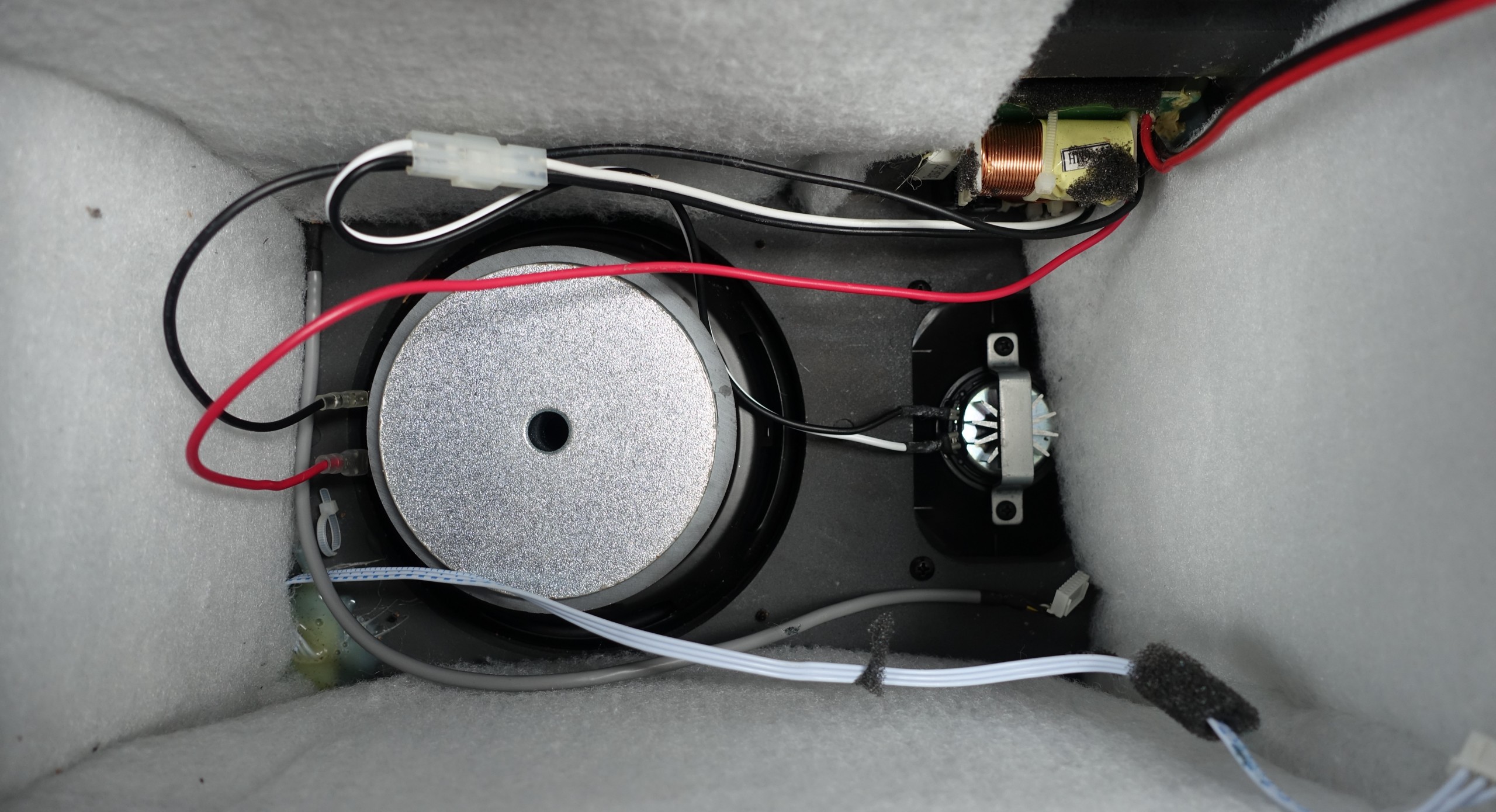

The very well stiffened body made of MDF is completely glued with simple foam mats on the inside of the sides, which is completely sufficient. A loose internal damping is not found, for reasons of cooling, on the other hand. The wiring is useful, the soldering points are cleanly worked and covered with hose.

The low-tone chassis of the 16 cm class (6.5") used has sufficient stroke, the membrane consists of a special Kevlar composite material with embossing, which offers a fairly good torsional stiffness with low weight. The beading is common in class.

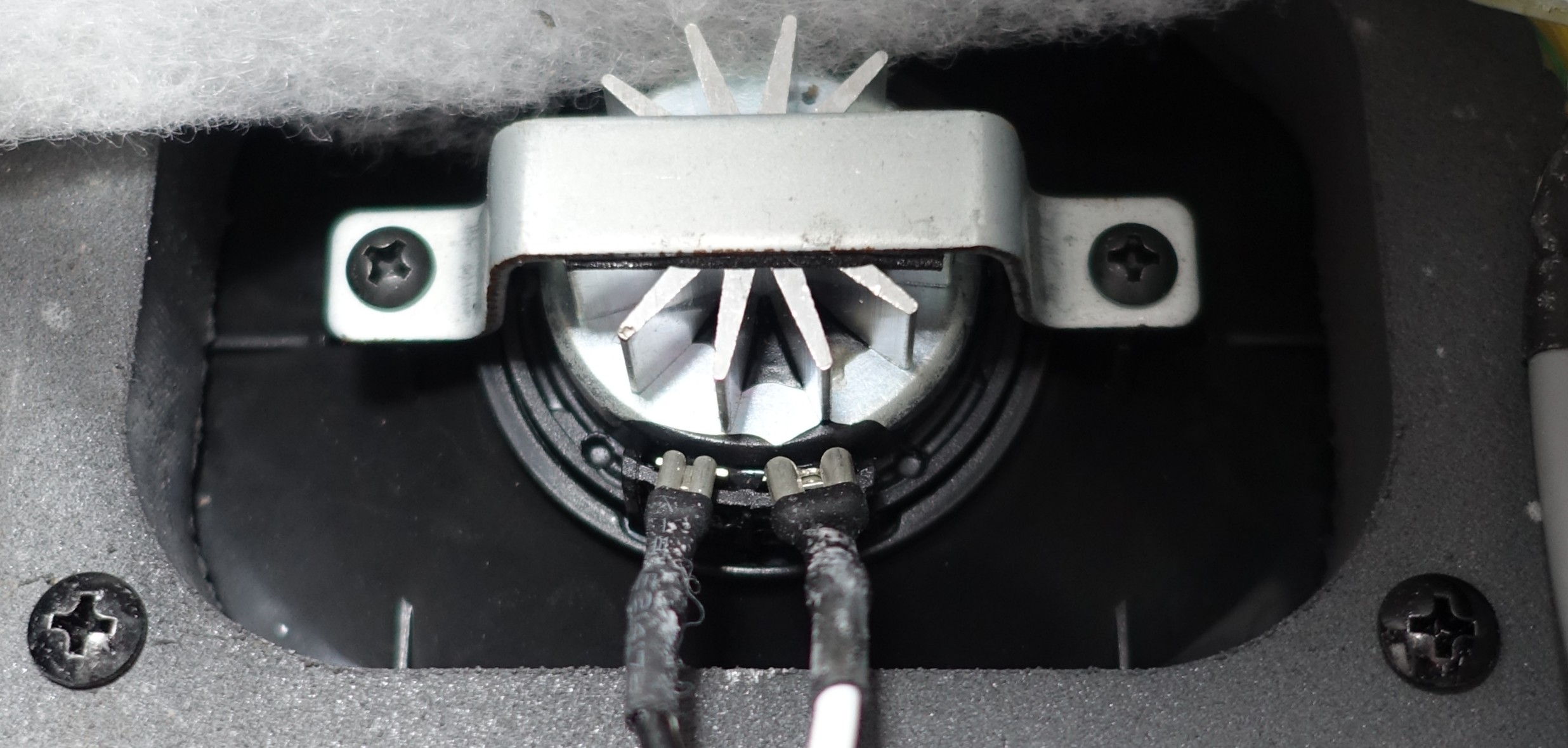

The 2.8 cm high-pitched carer is a neat silk calotte with fan heater above the magnet for better heat dissipation under high loads. Here, the manufacturer relies on cable lugs and hoseinstead instead of soldering points.

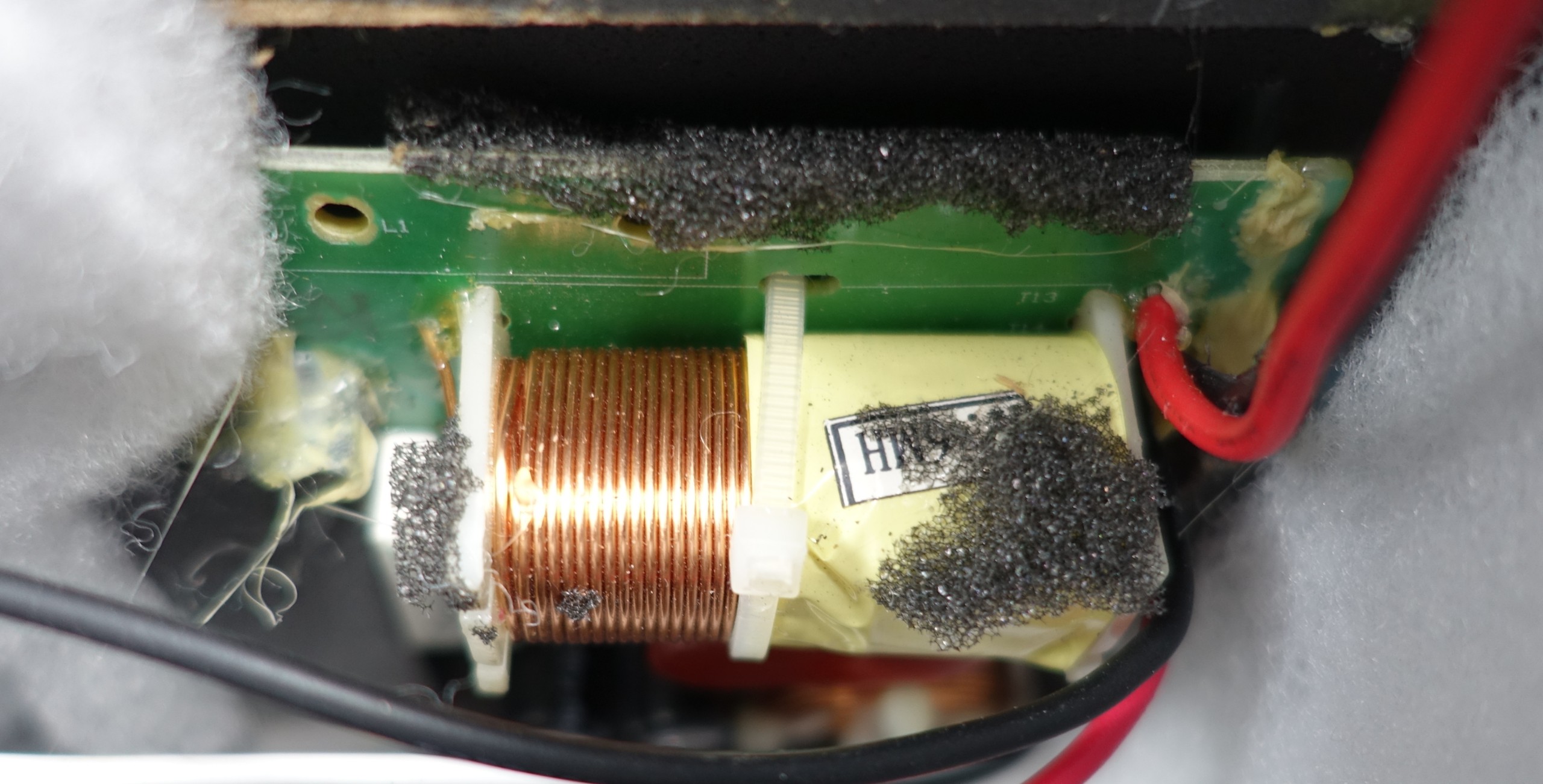

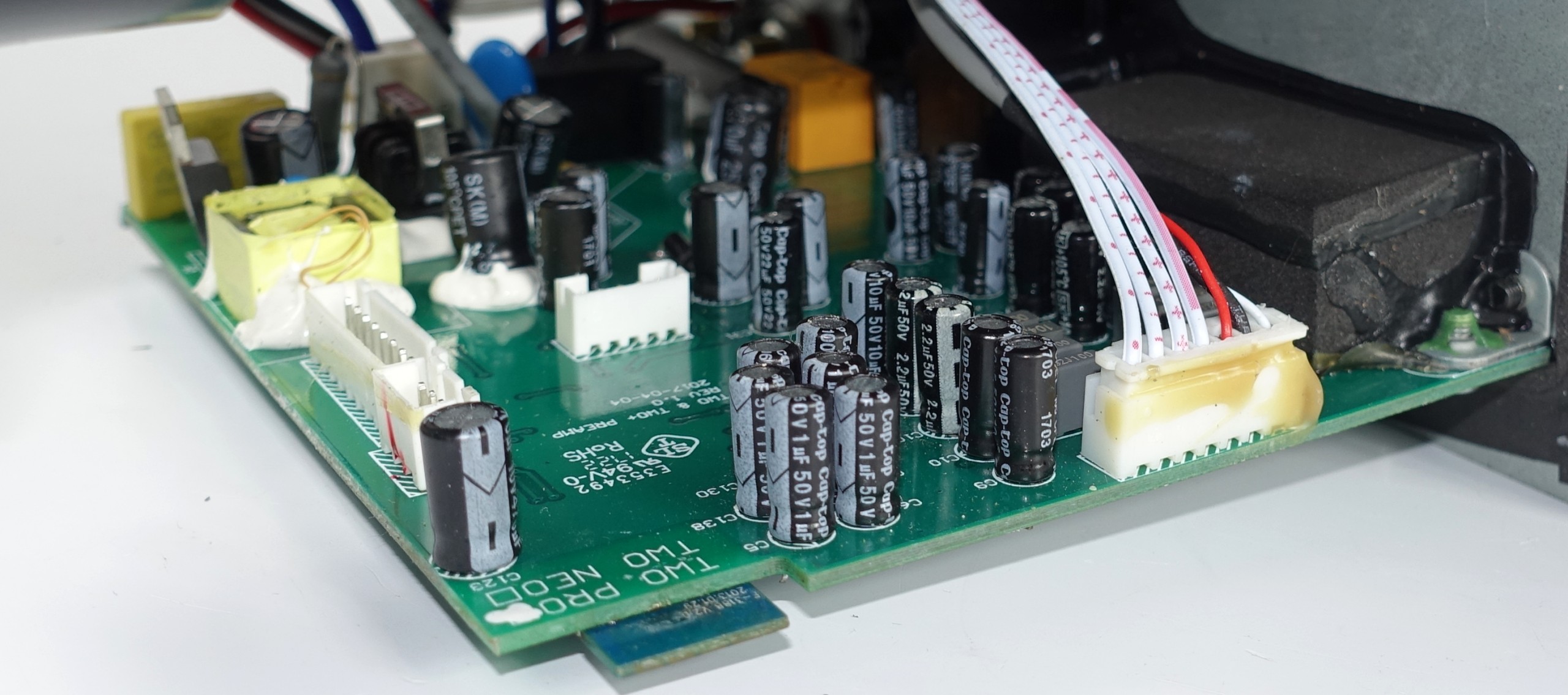

Both boxes have a passive second-order 2-way crossover, resulting in a flank slope of 12 decibels per octave. This board is not a mass-produced product, but has been specially manufactured for the Wavemaster Two Pro according to its own specifications in order to guarantee the most ideal adaptation to the installed chassis and body. This time, however, you don't rely on a tricky bending circuit, but on a normal LC filter.

However, for the super high tone on the turnout, a little trick was applied. Parallel to the level adjustment resistance for the tweeter, a small capacitor has been installed, which has the very high frequencies (from approx. 11-12 KHz), with decreasing resistance at increasing frequencies. We will see that this works quite well.

Power supply and amplifier

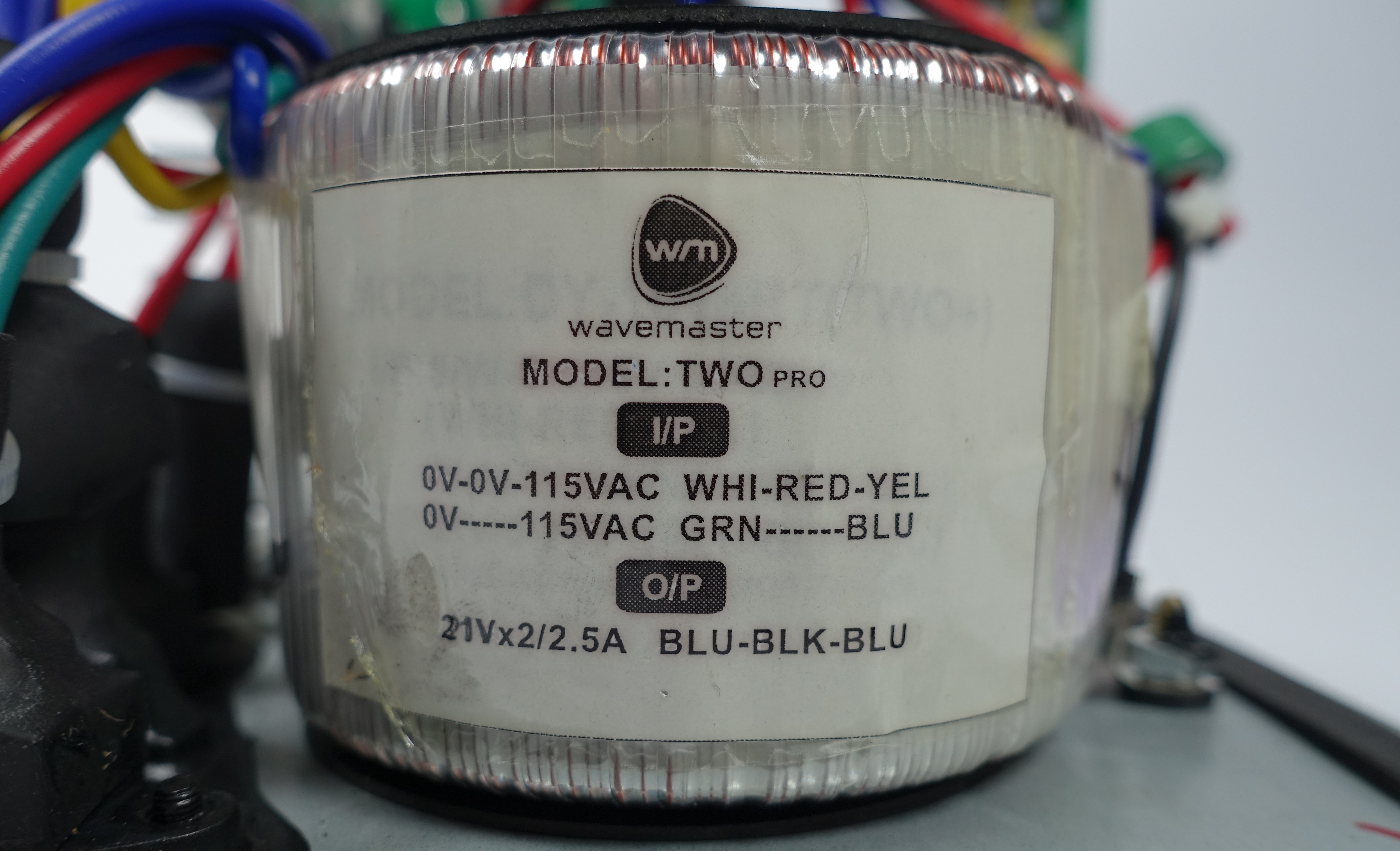

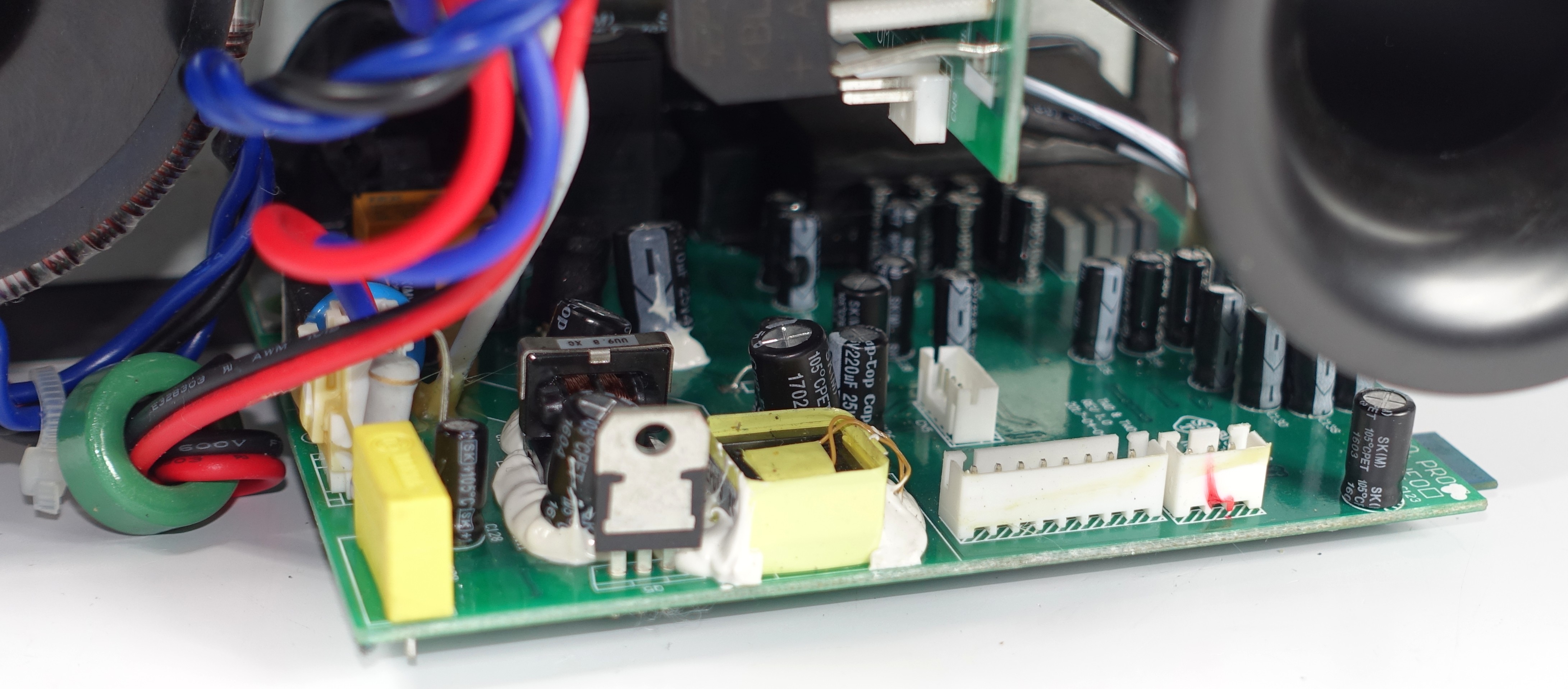

We also do not find a simple switching power supply for everything inside, but a real toroidal transformer, which is still used today in good amplifier solutions. This increases the weight of the active box and also reduces the net internal volume a little, but you can live with it well. In addition, there are various circuit knobs to comply with the required values in standby mode (ErP Lot 6). Well solved is so e.g. the automatic shutdown of the power amplifiers in the loadless state, if there is no signal for a long time, and the automatic switch-on when incoming levels are detected.

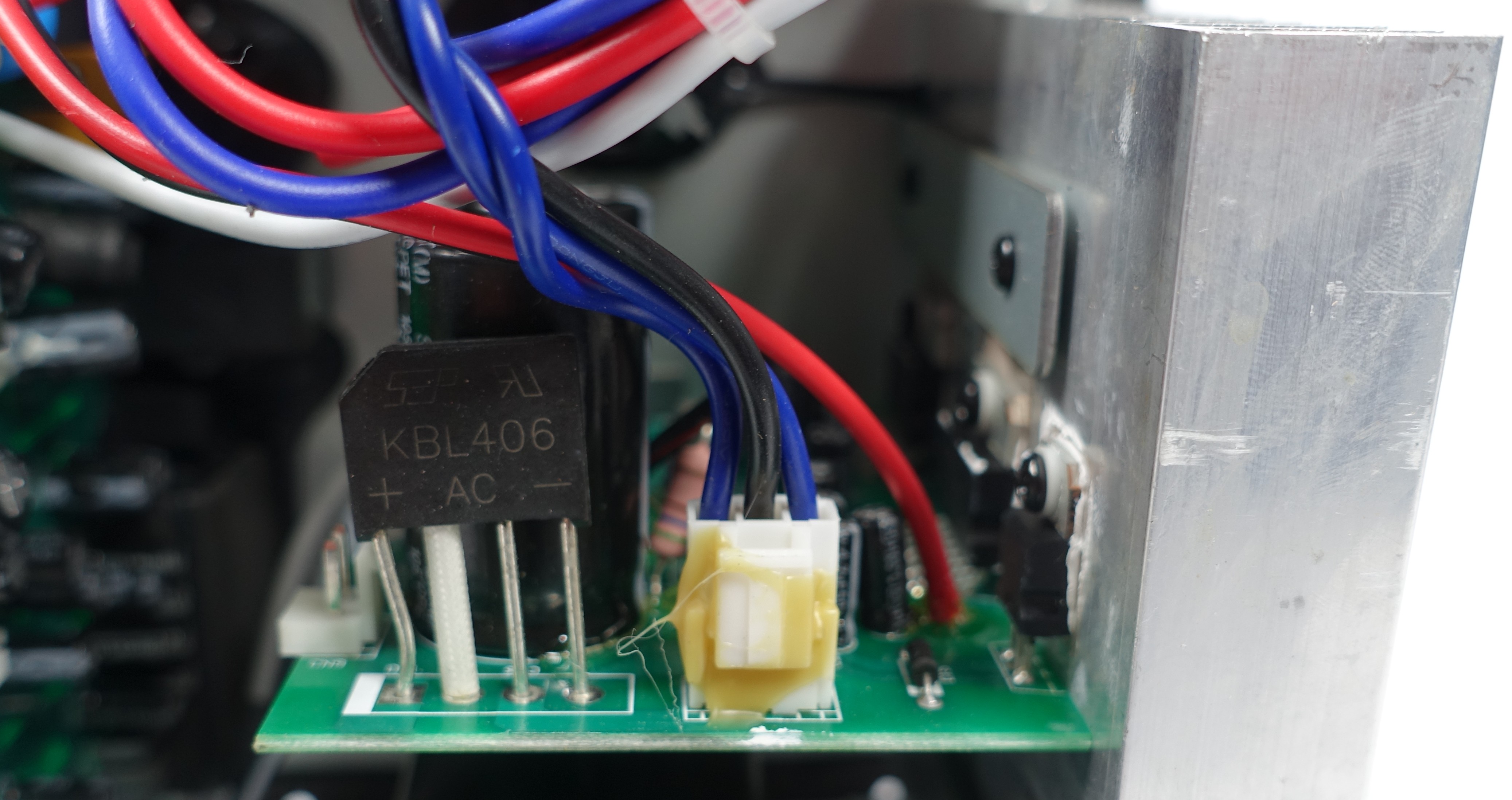

The rectictiincter circuit and power supply for the power amplifier divides the circuit board with the power amplifier. Wavemaster uses a KBL 405 as a bridge rectiveror. It is oversized, but does not require cooling.

The very "soft" power supply comes with short load pulses (e.g. so-called kick bass, i.e. the large drum). As with the Wavemaster Two BT, all boards are from Shenhzen Jin Shi Yu Eletronic Co.Ltd. and have an acceptable quality of assembly and soldering.

Wavemaster relies on a lot of OPV in the analog part (e.g. JM 4556) and the PT2314, which takes over the switching of the inputs as well as the sound and volume control. Bluetooth is implemented via a standardized additional circuit. This also shows that the interconnection has not changed fundamentally compared to the previous model. Since it is a pure stereo solution, there are no licensing costs for Dolby & Co.

The power amplifier has also increased considerably, in which, as in the Wavemaster Two BT, two TDA 7294 (one per channel) are used in the multiwatt 15V housing, which are actually good (depending on the transmission) even for up to 100 watts per IC. However, since such ICs are not used in the limit range, this time it is up to 50 watts per channel that can be called up. We wrote something about the power supply earlier.

With the Wavemaster Two Pro, as with the older models, HMC has thermally separated the solid rib-heatsink made of aluminium continuous casting from the back plate, so that in the end no one can burn the fingers on the back of the box. The higher the called output power, the higher the internal air movement in the box (basses), which can then actively cool these heat sinks.

Consequently, the bass reflex tube also serves as an outlet. If you are forced to dampen it a little with a foam rubber plug, you should take care not to drive the system at full load for hours, especially in the summer. The thermal reserves are actually sufficient even then, but you never know.

Kommentieren