This article is the premiere of the big topic 3D printing on IgorsLab, so I want to offer an easy start for beginners and interested people. I myself have been working with FDM printers since about the beginning of 2018 and own two different models with many tinkerings around them. What follows will be a mixture of generally important basic knowledge, tips and tricks (which I would have liked to have had myself at the beginning) and a bit of a field report.

The whole thing is planned as a multi-part, the following introductory article is revised and updated from time to time. But I don’t want to anticipate too much yet, so I’ll start straight away with the first question:

What is 3D printing and what can you do with it?

To explain this, one can also quote Wikipedia:

“3D printing, also known as additive manufacturing, additive manufacturing, generative manufacturing or rapid technologies, is a comprehensive term for all manufacturing processes in which material is applied layer by layer to create three-dimensional objects (workpieces). The layer-by-layer construction is computer-controlled and consists of one or more liquid or solid materials according to specified dimensions and shapes. Although these are often forming processes, no special tools are required for a specific product, which have stored the respective geometry of the workpiece (for example casting moulds). 3D printers are used in industry, model making and research to produce models, samples, prototypes, tools, end products and for personal use. In addition, there are applications in the home and entertainment sector, the construction industry and in art and medicine.”

– abridged Wikipedia definition

If you undo the very formal text and focus on the most important points for the private plastic melter, I will summarize it as follows:

3D printing is a technology where an object is produced layer by layer. Depending on the printer, there are different materials with different properties to choose from, the shape of the object to be printed can be “freely” selected and the whole thing is a computer-controlled process, similar to a CNC milling machine or laser cutter. Whereby I would like to note here that a computer is only needed for preparation, not permanently during printing itself. You can make a whole lot: from toys to useful little things to unsaleable spare parts.

Do I need a 3D printer?

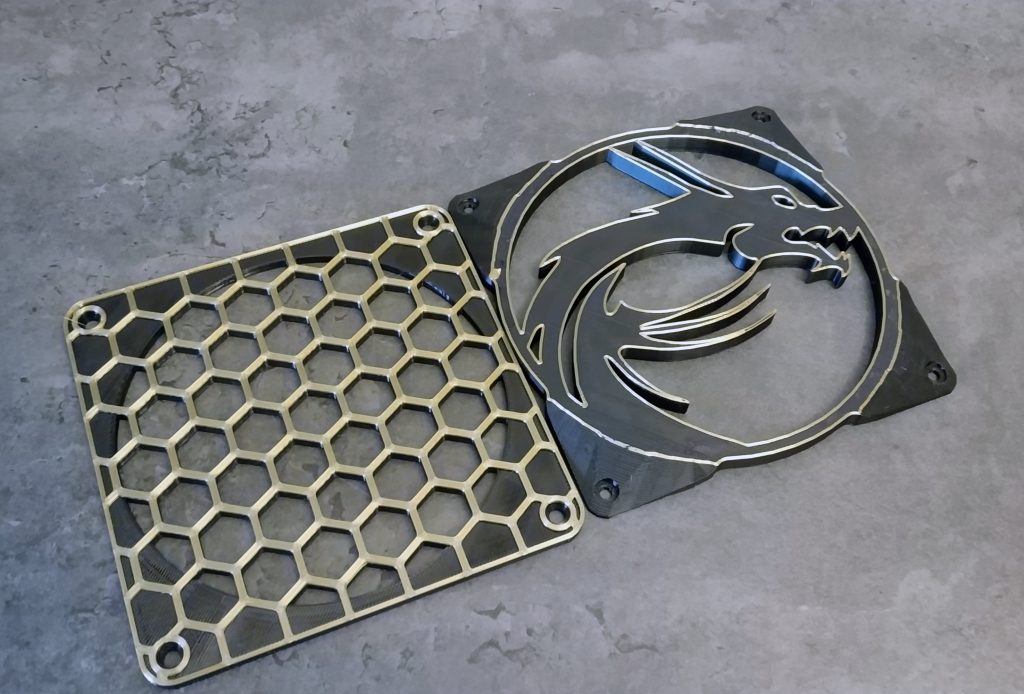

Of course everyone has to answer this question for himself, but at least I can give some food for thought. In my experience, buying a 3D printer goes very well with another hobby, whether it be model making, drones or Warhammer 40K figures. For my part, I have already printed graphic card holders for vertical mounting or a holder for fans to cool the VRMs, to show the relation to the hardware world. The possibilities are manifold, provided a little creativity.

I don’t think it makes much sense to first buy a printer and then to think about what you actually want to do with it. This usually ends with the fact that after a month you don’t know what to do with the thing. Of course, if you just want to start a new hobby and learn more about CAD, there is nothing wrong with that. Last but not least there are many enthusiasts on the road here … there is need and want to have something fundamentally different.

Kommentieren