I recently had an article where I successfully used Thermal Putty on a graphics card. It is ultimately a highly viscous thermal paste (often referred to as thermal adhesive). Thermal Putty is a highly interesting (and often misunderstood in DIY) material used between electronic components and heat sinks to improve heat transfer. Traditional thermal pads, on the other hand, are prefabricated, solid materials that are also used to improve heat transfer. Thermal Putty also generally retains its heat conduction properties longer, while thermal pads can dry out and lose efficiency over time. So far, so familiar.

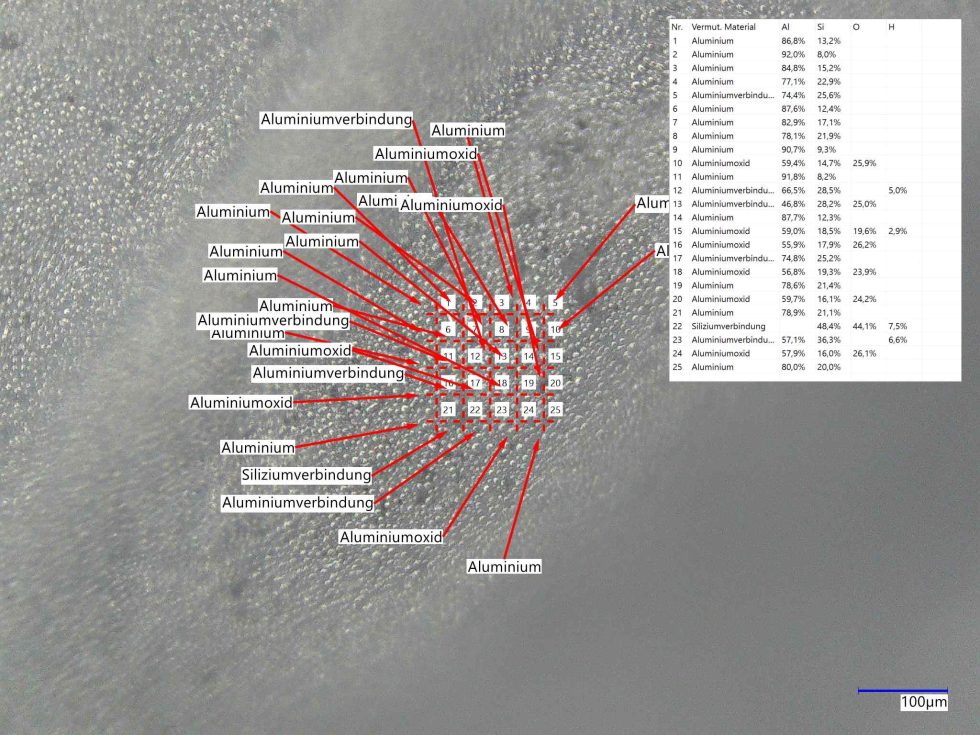

After all, I already published a LIBS analysis of three thermal conductive pastes this week, and I figured why not analyze the three samples of Thermal Putty I have? LIBS stands for Laser Induced Breakdown Spectroscopy. The unit used by KEYENCE (EA300) for the analysis of materials employs exactly this method, which relies on the use of a highly safe class 1 laser. In this process, the laser used converts the surface of the object to be analyzed into a plasma state. In the process, atoms and molecules of the material are ionized, causing them to emit light. If you want to know more about this, feel free to read the initial article again, it’s really interesting.

So much for the theory,but what about the samples now? I have three samples from Halnziye, the HY234 (4 W/mK), HY236 (6 W/mK) and HY883 (6.5 W/mK). In my test with the real graphics card, I had intuitively gone for the HY236 and the analysis will show why I was absolutely right. The HY883 is actually a rather viscous thermal paste and is often sold as such. Some sell it as Thermal Putty, which is actually completely wrong. We’ll see why in a moment.

Preliminary test: Bleeding of the samples

It is fascinating how well such a trivial test works again and again. We already realized that yesterday. And no, this is really not absorbent kitchen paper, but a normal white 80 g sheet from the copier. You can already see after 10 to 15 minutes that, especially with HY883 as a paste, a lot of binder bleeds out. With the Thermal Putty, everything is within the green range, whereby the HY234 is even supposedly somewhat less susceptible than the more clearly colored HY236. But that can also be deceptive.

Why HY833 is not a thermal putty

I had just shown that the HY883 is really a thermal paste and not a Thermal Putty. Still, of course, I’m looking to see what can be found in it. Aluminum(oxide), silicone and also hydrogen again. I write but on the next page at the Thermal Putty still something to the production and where the water could come from. As a thermal paste, the Hy883 is thus nothing special, but it at least sticks nicely. At least something. The ample 6 W/mK are quite honest and real, and if you look at the price, then it fits.

Let’s surprise ourselves and see on the next page where the journey of Thermal Putty goes and what is in the two remaining relevant samples!

Thermal paste comparison with laser-induced plasma spectroscopy: We discover a violet surprise!

49 Antworten

Kommentar

Lade neue Kommentare

Urgestein

1

Veteran

1

Urgestein

Urgestein

Mitglied

Urgestein

Veteran

1

Mitglied

Veteran

Mitglied

Veteran

Mitglied

Mitglied

Urgestein

Mitglied

1

Alle Kommentare lesen unter igor´sLAB Community →