Update from 19.07.2023 – 02:30 pm

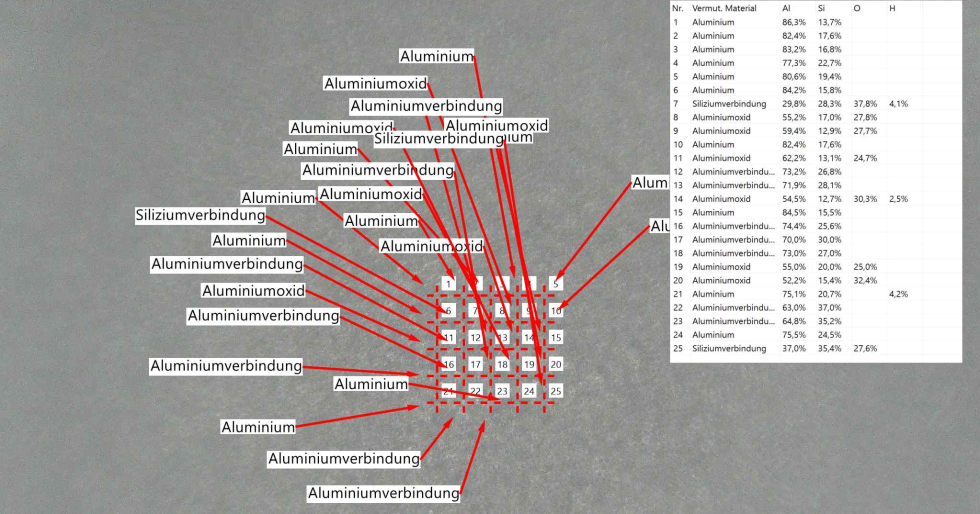

Since the Cryo Fuze is supposed to be mainly composed of aluminium (I will, of course, not disclose the actual recipe for certain reasons), the absence of any aluminium traces over so many measurement points is indeed interesting and an important finding for Cooler Master. In consultation with the manufacturer, I will soon test other batches (including from abroad), as it could also be a major mishap of the filler. Such a thing, of course, must not happen, and a clarification is in the interest of Cooler Master to protect the product. But we will naturally stay on top of this.

Original article

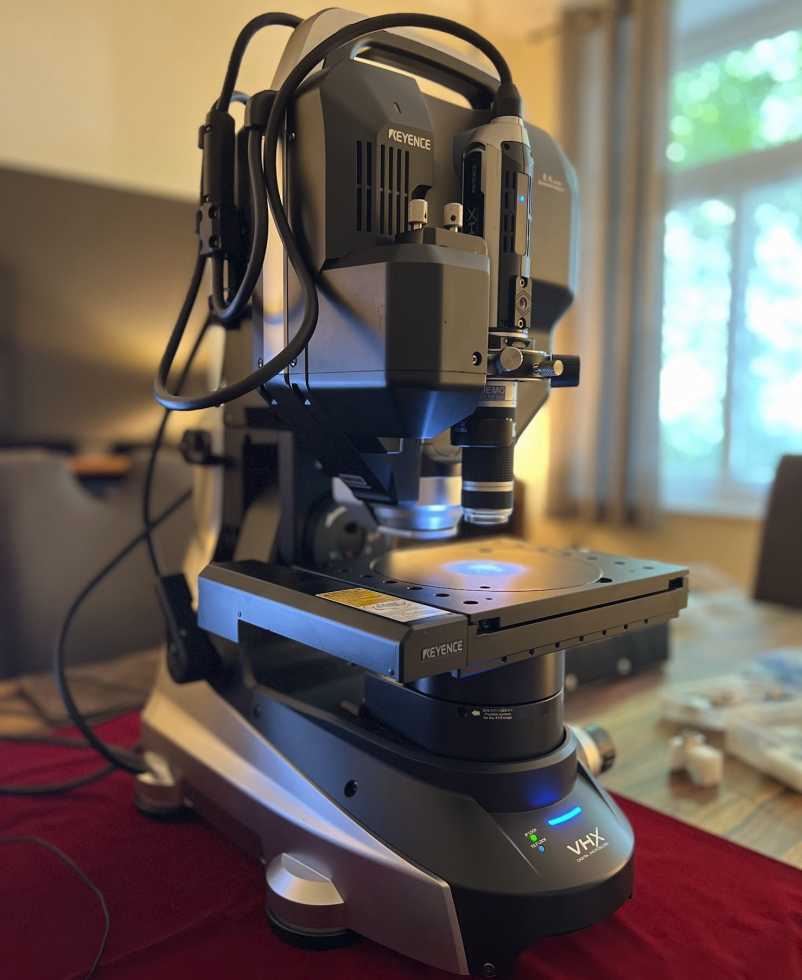

I recently had a visit from KEYENCE in the lab and it was interesting to see how the technology is developing. Instead of time-consuming analyses by SEM (scanning electron microscope) and material analysis with EDX in vacuum, where we always have to remove all liquid components first, the whole thing can now be done quite simply and without any preliminary work! And since I was extremely curious about how it all works, I simply examined three thermal pastes. This is on the one hand the Alphacool Apex, which I like to use, and on the other hand in direct comparison the MasterGel Maker V2 and CryoFuze Violet from Cooler Master. Especially with the fancy colored CryoFuze I was curious where the stated 12.6 W/mK should come from. So it will be exciting!

We measure with LIBS

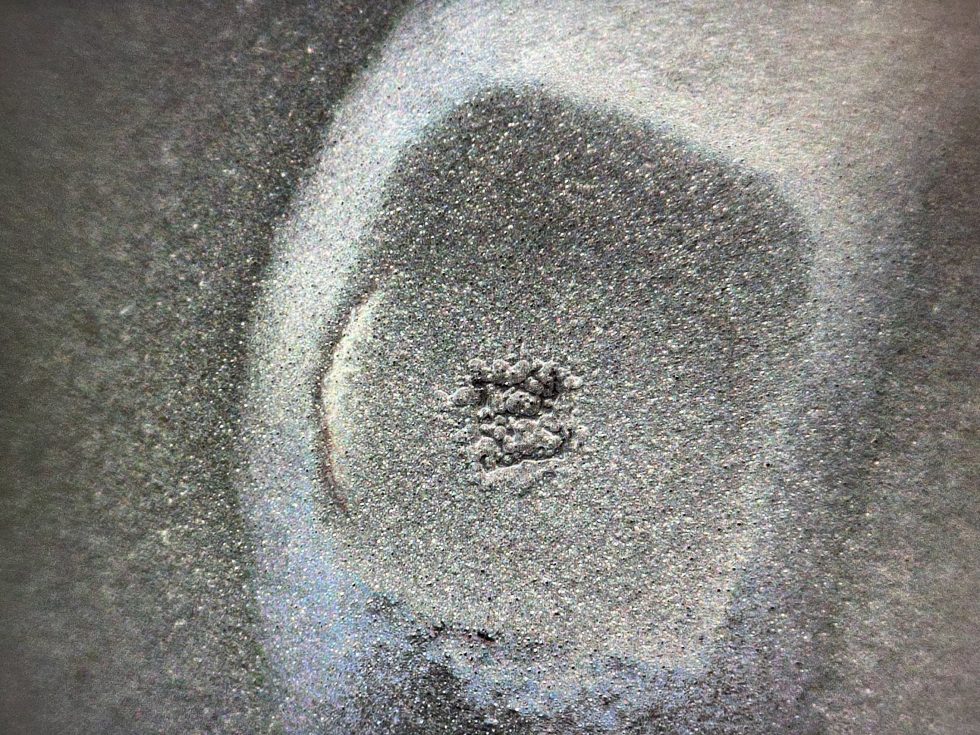

Before we measure anything, I want to briefly explain the term and the method behind it, because it doesn’t work completely without background. LIBS is an acronym for Laser Induced Breakdown Spectroscopy. The KEYENCE unit (EA300) visible in the picture for the analysis of materials uses exactly this method, which relies on the use of a highly safe class 1 laser. In this process, the laser used converts the surface of the object to be analyzed into a plasma state. In the process, atoms and molecules of the material are ionized, causing them to emit light.

To measure and evaluate this emission, a high-resolution broadband spectrometer is used. This instrument is capable of detecting and analyzing a broad spectrum of light colors, ranging from the deep ultraviolet to the near-infrared. This broadband capability allows for a comprehensive analysis of the various elements contained within the material, as each element emits a specific color or frequency of light. The design of the system used here is such that the microscope’s objectives are positioned on the same axis. This special arrangement optimizes the detection of elements in the measurement area. This concentrated and precise analysis allows the material analysis unit to provide accurate and reliable data on the composition of the material under study.

So much for the theory, but what happens to the data? The device used is equipped with an extensive internal database containing thousands of material structures. This resource allows the system to quickly make a prediction of the most likely material name based on the identified elements. To increase usability, the material data is organized in a hierarchical structure. This simplifies access to specific information such as the specific material name, the generic name, and the description of the material. So a kind of EDX for dummies and in really fast. Well, and you don’t have to clean anything afterwards either.

In addition to the material structures at hand, the database also has the ability to store previous internal analysis results and retrieve them as needed. So if similar foreign particles are detected in later analyses, these earlier results can serve as a reference. This feature not only makes work easier for experienced users, but also allows inexperienced users to identify materials in a simple and efficient manner. The combination of a comprehensive database, intuitive structuring, and reference capabilities helps optimize material identification for users of all experience levels.

The compact and removable unit houses specialized triple optics for viewing, laser and spectroscopy. It is designed to provide a central laser transmission path with SLR optics close to the lens, enabling high-performance focusing of plasma emission. Thanks to the combination of KEYENCE technologies, components have been significantly reduced in size while still achieving high performance. The unit offers an innovative function to link the field of view and focus.

This allows the microscope objective and laser objective to share the same field of view by simply moving them. This eliminates the need for alignment and focus adjustment during analysis. Changing and attaching the most appropriate objective is simply convenient, regardless of the magnification level. The measurement is not entirely non-destructive, but it also allows one to remove layer by layer and re-measure the underlying areas. Advantage vs. disadvantage – you can weigh it.

But enough of the theory, because in the end we want to know what is really in the pastes. After all, I don’t want to sell you such a device, but only show you what is possible with it. That’s exactly what you’ll get after turning the page!

Danke für die Spende

Du fandest, der Beitrag war interessant und möchtest uns unterstützen? Klasse!

Hier erfährst Du, wie: Hier spenden.

Hier kannst Du per PayPal spenden.

105 Antworten

Kommentar

Lade neue Kommentare

Urgestein

Mitglied

Urgestein

Mitglied

1

Urgestein

Urgestein

Veteran

Urgestein

1

Urgestein

1

Veteran

Urgestein

Mitglied

Urgestein

Veteran

1

Urgestein

Alle Kommentare lesen unter igor´sLAB Community →