Today I happened to come across another review of a thermal compound, which I was amazed to read and almost lost my eyes. Sure, whoever receives a test pattern in the social medium should find it nice if possible (at least that’s what the PR company hopes), but at least the tester shouldn’t get caught beautifying and find temperature differences that are theoretically never possible in life. You can easily calculate these differences. You don’t believe that? Yes, it is even relatively simple, once you know how…

Don’t worry, it’s not a boring school lesson, on the contrary. But I can’t spare you some math and physics. And that’s a good thing, because in the future everyone will be able to calculate for themselves what they need or think they need or where they still have to work on their own application skills. With this I would have elegantly spoiled the sequel, which of course will come as well. But back to the paste, because there is still a lot of need for clarification! Also with regard to graphics cards, because there are quite different laws.

What a heat conduction paste has to solve and what not

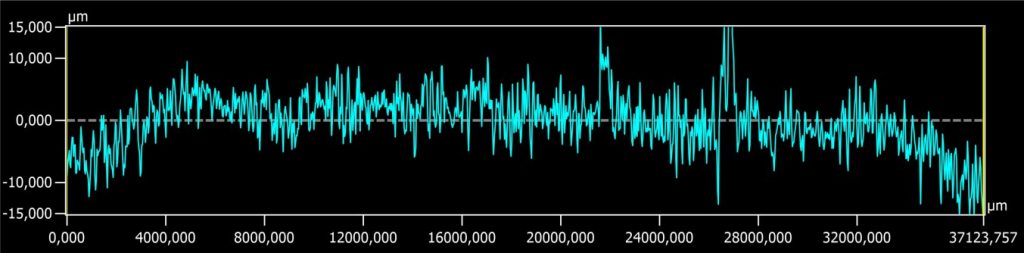

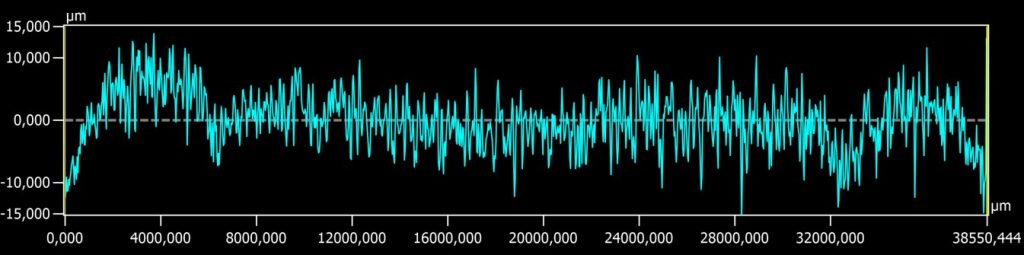

There are no really smooth surfaces, even if at first glance they might still look like them. Want to see a cool, unused CPU? I have something from AMD, so please be brave. Under the microscope I see something like that:

But also the Intel fanboys have no reason to laugh gloatingly now, because such a Core i9 doesn’t look any better under the microscope. Different heatspreader, same problem. But look for yourself:

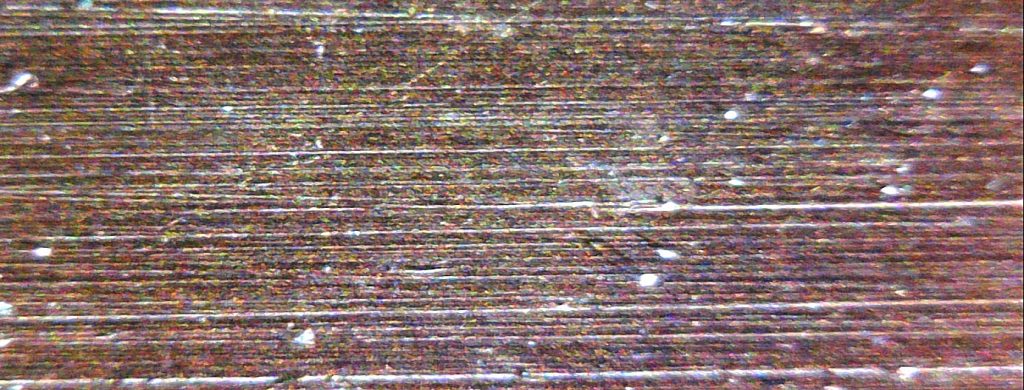

Well, and the coolers… The one on the next picture is the strongly magnified copper bottom of a supposedly smooth cold plate. Beside the tool traces, which were already created during grinding in the factory, we can see the light remains of the first thermal compound, which have crawled exactly where they cannot be easily removed with a normal cloth. That’s why suitable solvents are always the first citizens’ duty when it comes to cleaning. Isopropanol is a good champion against the residual paste collapse. What good is the best paste if the old paste sticks even more firmly in the cracks than many politicians on their chairs?

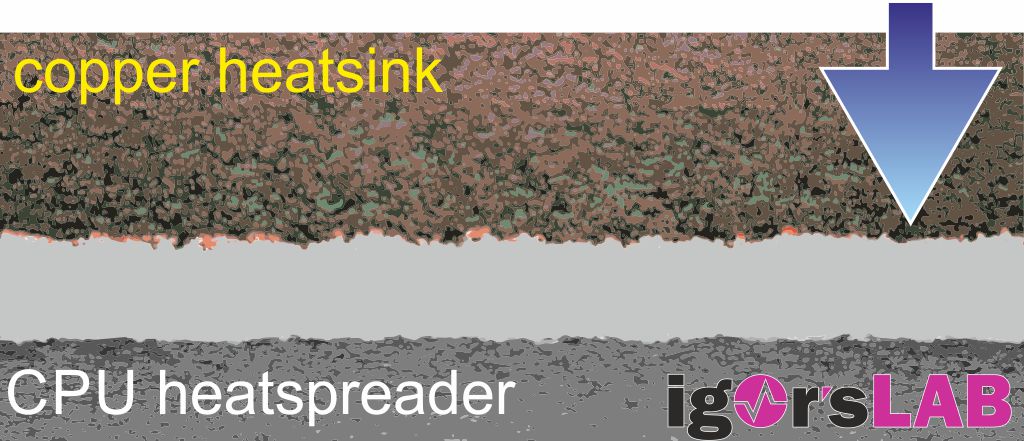

If you now bring two such surfaces together, i.e. the CPU heatsink and the cooler heatsink, then the thermal compound must fill in all unevenness and air gaps and thus also completely exclude the air, which is an almost perfect insulator. The result is a composite of a total of three materials, in which the thermal compound must now be of more interest to us. Because two things are of primary importance here: the thickness of the layer and its thermal conductivity or, conversely, its thermal resistance. The former air layer between the CPU heat spreader (dark grey) and the copper base (reddish) is completely filled by the paste (light grey):

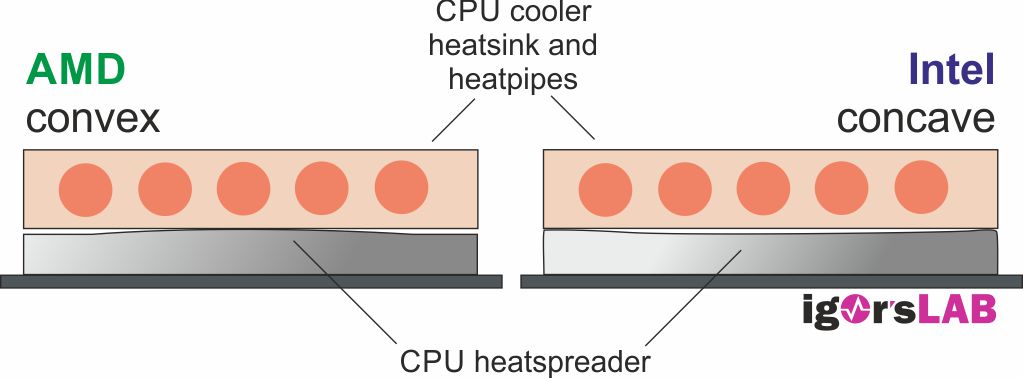

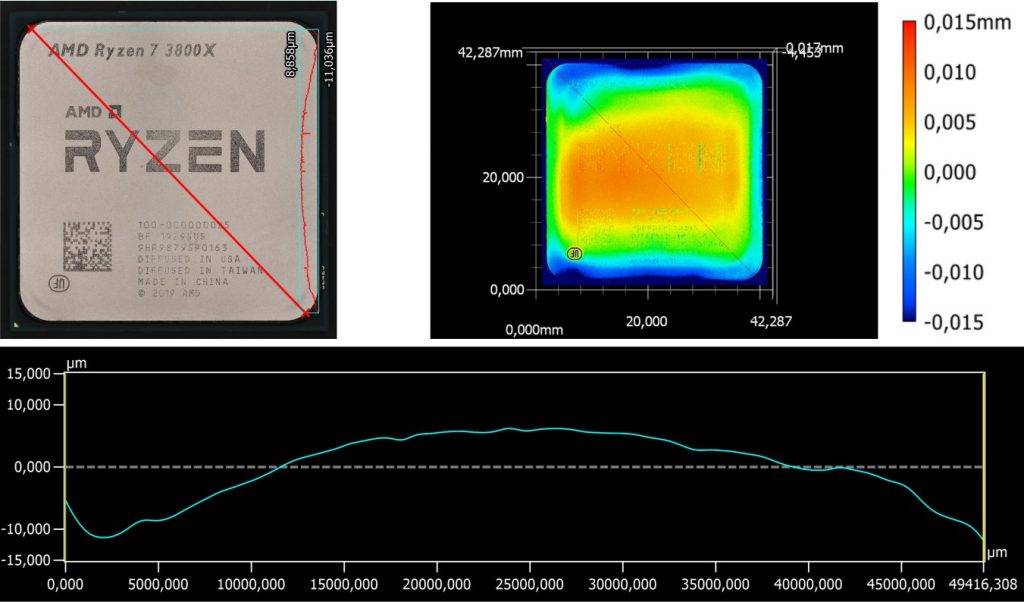

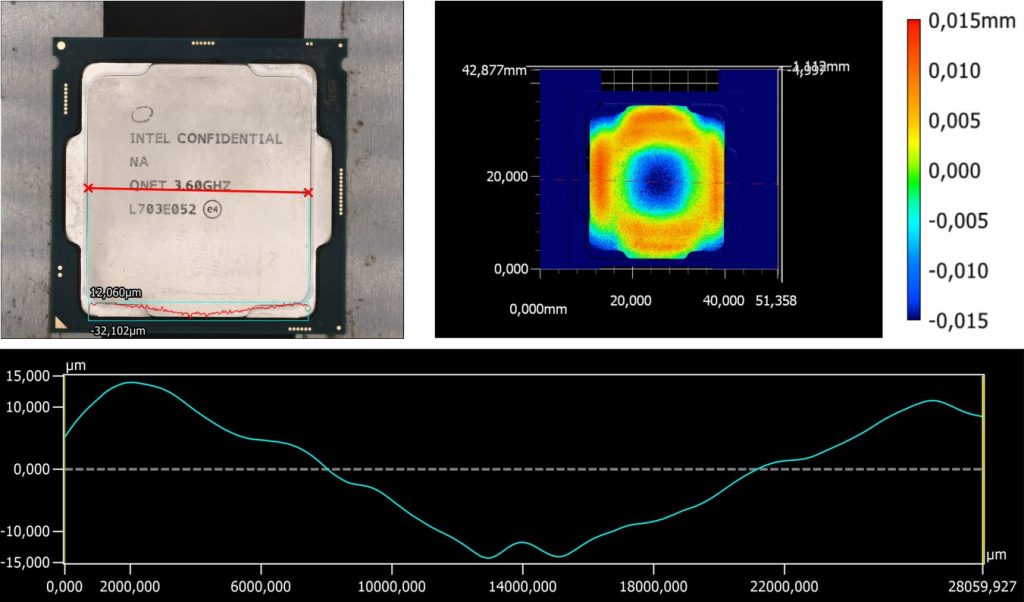

In addition to the grinding marks and unevenness of the material, the shape of the heatspreader also plays a role. The manufacturing processes are somewhat different, but so is the curvature. The scheme below shows (somewhat exaggerated) why it is not possible to do without thermal grease and why the processors of both manufacturers also require some thought when applying. Superfluous paste will be a bit easier to leak from the AMD processor than from the Intel processor, which leads to a thicker layer more quickly. And what that leads to, we’ll discuss in a moment.

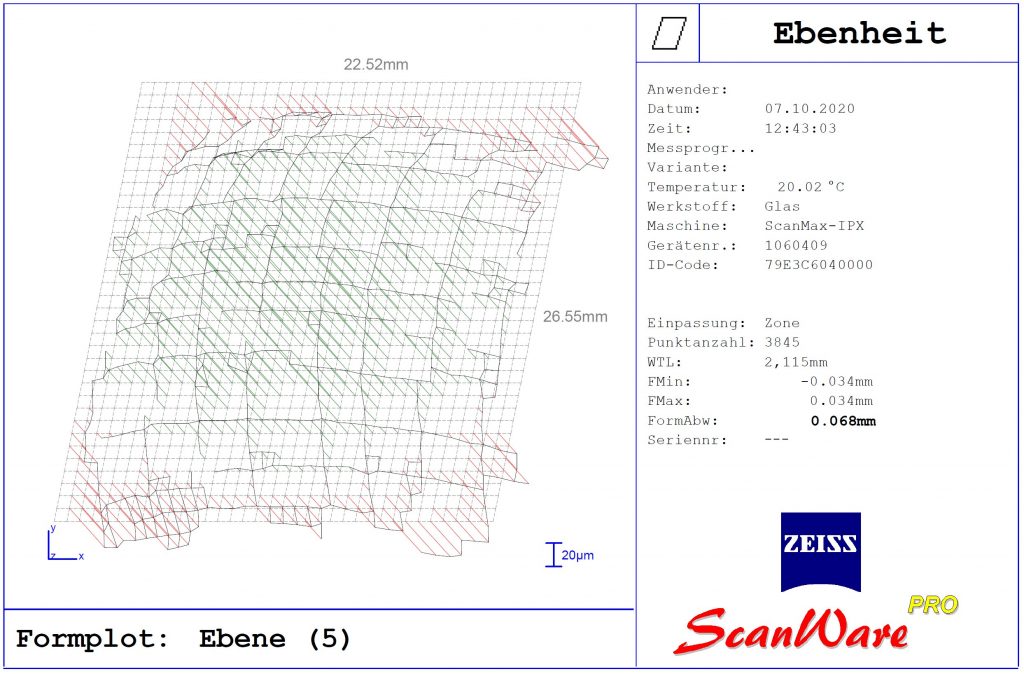

I can also give you a practical example here, whereby I even measured the somewhat flatter processors that have already been used once. Let’s start with AMD again, in this case it is a Ryzen 7 3800X (which could also be an example for a Ryzen 7 5800X, because the IHS remains the same):

And now all that again for a more up-to-date Intel CPU:

Also interesting: CPU-Heatspreader imCPU heatspreader examined in detail – do we now have to redesign the coolers for AMD and Intel?

Graphics cards deviate slightly here because the chip is exposed. The most important thing is to fill the possible gaps between the very straight and smooth die and the cooler base. Except for the known problems with curved bottoms of the vapor chambers, you can (and must!) work with significantly lower layer thicknesses here. Unless you have a current Ampere card, such as an RTX 3080 or RTX 3090, where even the chip is convex:

I will exclude the liquid metal fraction anyway, because the whole thing is subject to the same laws, but almost approaches the ideal due to the metallic compound. If you still want to calculate later, you can still do this (and then indicate with the result). And if I am honest, a good paste together with good skills of the user can still achieve results that are not bad. How to do it. But for that I have the follow-up already promised above.

Also interesting: GeForce RTX 3080 and RTX 3090 with bended package – why water and air coolers have such a hard time

Marketing and truth

No one can reinvent physics and launch groundbreaking products that promise extreme differences. Sure, a little better is always possible, but at the moment we have already reached the limits where conventional pastes can hardly do significantly better. The pastes are now almost all really good, if you do not just fall back on an absolute discontinued or budget product. Thermal pastes are typically characterized by their highest possible thermal conductivity in terms of watts per meter kelvin (W/(m*K)). Celsius and Kelvin are synonymous here, as it is solely a matter of the rate of increase in temperature and the rise or fall in temperature is indicated here. This indication and why this is composed in such a way, I will explain shortly.

It is precisely this “K” value of the thermal conductivity that marketing discovered for itself some time ago and drives the helpless, small K through the village as a compliant sow. The higher the value on the box, the more expensive the contents can be sold. Now, of course, it is not the case that the “K” value is completely irrelevant, but we want to calculate right away which difference is really noticeable and where the snake oil wellness begins. And the usability is also another factor that can influence the results achieved in practice more than the pure chemical composition.

Whereby it is not even sure that the printed values are correct at all. You can hardly check it anyway, especially since even the manufacturer sometimes does not know or cannot check what he has actually printed on it and what is really in it. Or he knows, but simply continues to use the certificates and values of the former bottler, although the content is fundamentally different. Well, units are not that important, the main thing is that the number pays off. The industry remains silent, mostly for good reason. Because the pastes are really manufactured by third parties and only then reach the tradesman in terms of thermal paste via the bottlers and processors. And often enough, you then actually get an identical paste under different names from different suppliers in the stores. The profit margins? Tempting!

Skills versus snake oil? Not quite, but we’ll see in a moment on the next page that math can actually be fun. So I’ll hold the formula stick out to you in a moment, only you’ll have to jump over it yourself. But that will be alright.

Kommentieren