Of course, you’ll be amazed if, for example, three supposedly identical cards from one manufacturer have completely different temperatures or fan speeds and this is then reflected very similarly in the reviews of colleagues, which are supposedly contradictory. No, it’s not that the editors don’t know what they are doing, it’s just that they don’t know why things are the way they are. But first of all, one has to get behind it, which also requires the necessary equipment for measuring, which cannot be taken for granted. And even the precise manufacture of cooling blocks can suddenly and unexpectedly take revenge if a manufacturer really takes the gap dimensions very seriously and is then amazed.

Important preliminary remark

Since especially the colleagues on YouTube and news aggregators like to overlook or shorten the contexts and important remarks in the hunt for the quick click, this time I’m going to introduce an extra explanation that really needs to be taken note of. All the values listed below were communicated to NVIDIA in advance and commented on as “within tolerance”. Please bear this in mind.

This is fine at first, but tolerance ranges are a very elastic term, because you never know when such a tolerance limit was defined. As a guideline for the parties involved in the production chain up to the finished package or only after the first experiences with a new production, where the large gap dimensions are then raised to the new standard and the production chain has to react to the package? That doesn’t really matter either, because it is the way it is. You just have to know and always plan for it. Also as a causal chain, when several factors come together.

Of course, I am not entitled to make a judgement here, as I am not a chip or graphics card manufacturer, but the counter-question from someone involved in the cooling chain must also be allowed, why of all things it is being approached so generously this time, when the general conditions of a lot of energy to be dissipated speak a different language. So today’s article contains what I personally noticed and where I also see problems for the cooler manufacturers and ultimately the end user. The problem is now also known to the board partners, cooler OEMs and water cooling producers and much of what I describe today has been verified or is even based on the initial reports of the industry involved.

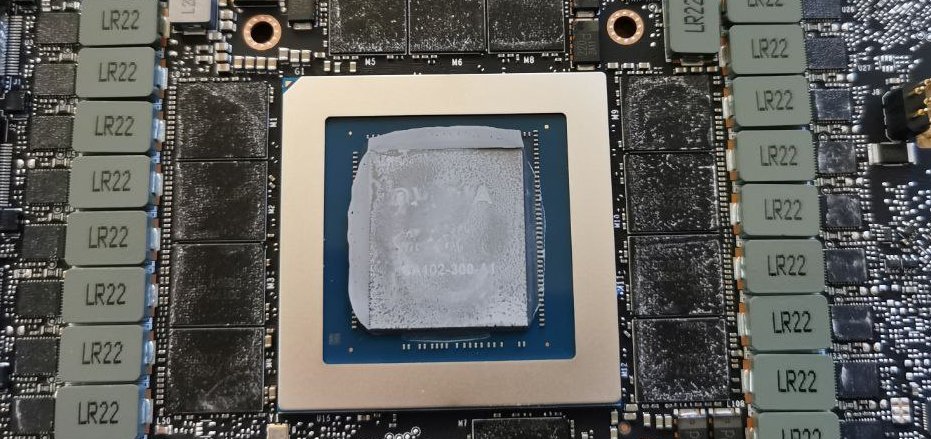

Problem zone 1 – the convex die

We see at the picture above (RTX 3090 FE) on the basis the distribution (and quantity) of the heat conductive paste, with which high contact pressure was worked. The center of the resulting and cured impression is highly compressed and you can even read the chip’s labeling while the corners are falling off sharply. If one assumes that such a layer is sometimes 0.1 mm or thicker, then a concave surface can already be seen here. But how does that actually work, because the die is completely flat (has been created)?

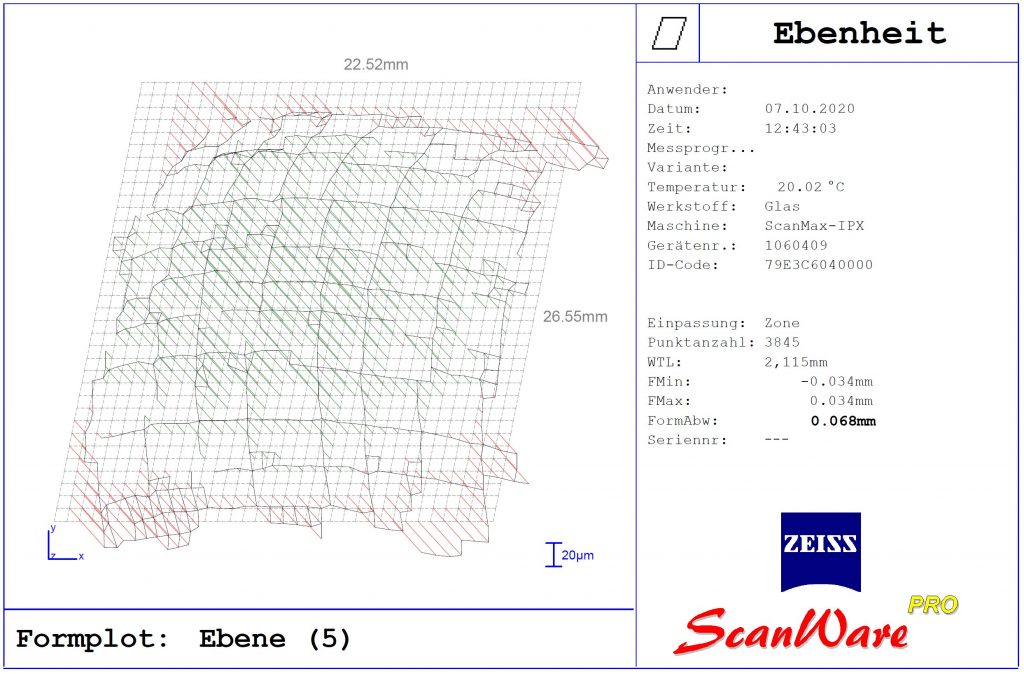

Here the cause is to be found in the packaging, but I will come back to that in a moment. The concave curvature already existed with Turing, but not so extreme and also the overall height of the package was much more uniform. In order to prove this now, we once measured a rather average graphic card at 20°C room temperature. The curvature of the die is with 0.068 mm (according to NVIDIA within the specifications) still in the tolerable range, but I also had a card with a little over 0.08 mm. This can be done quite well with heat-conductive paste, if it is not too liquid and in the end it differs only little from Turing. Here is the form plot for flatness:

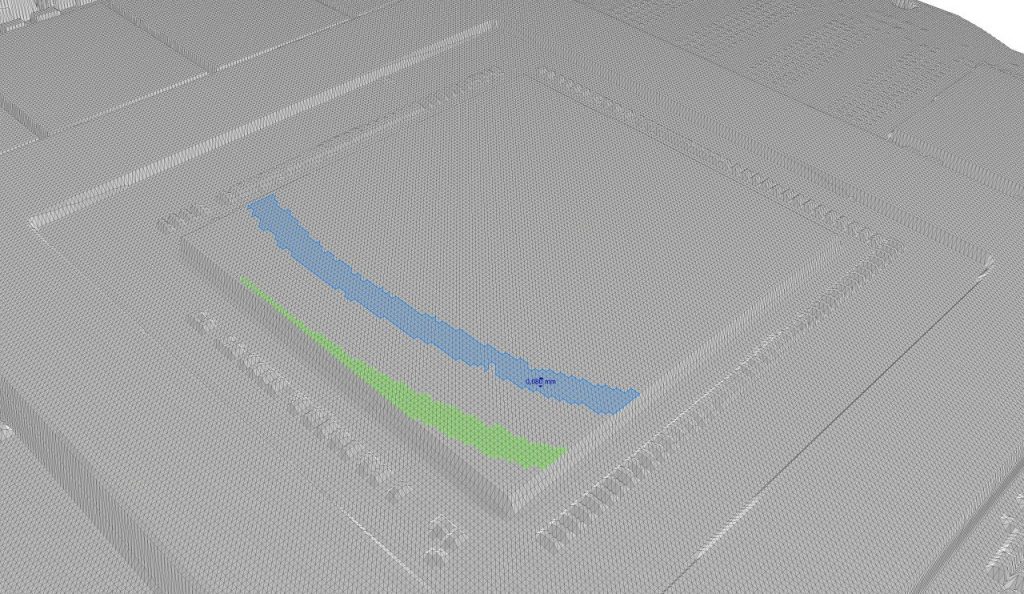

Parallel to this, I scanned an extreme case myself in high resolution 3D. Here, the curvature in the die is 0.08 mm and more in places, which raises questions about how such a thing can arise.

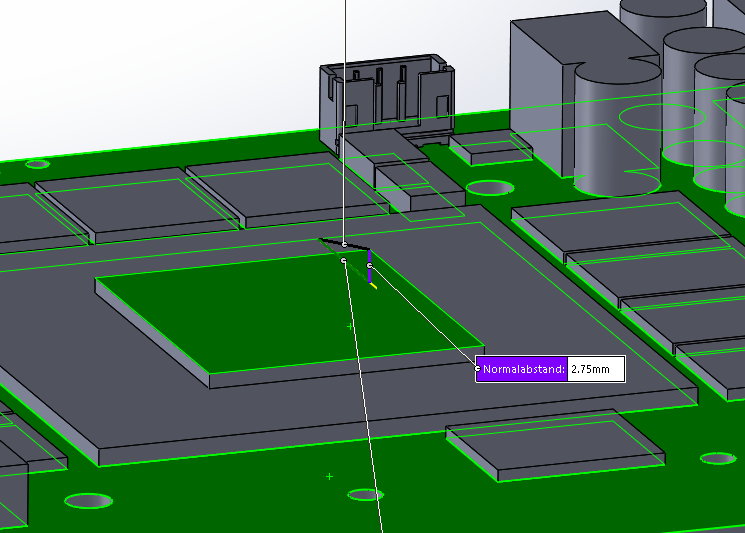

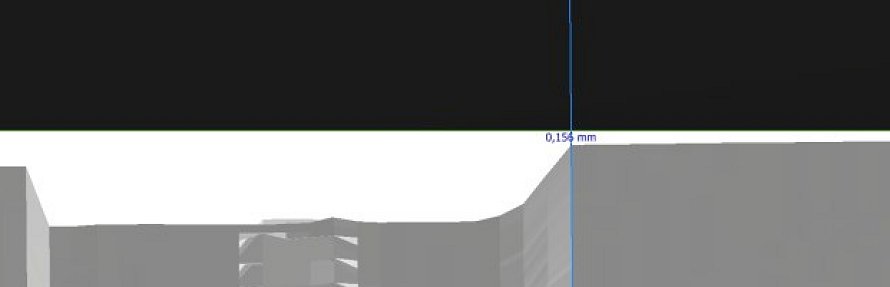

So far, so well known, even if the curvature is rather unattractive. But it’s still manageable because, according to NVIDIA, it’s still within specifications. Unless the whole board (including the package!) is already warped like on my scan of the GeForce RTX 3080 (the black one represents the bottom of the cooler and the plane), then it becomes a bit clearer.

In such a case it is also very difficult to get an exact centering and there is a gap of 0.156 mm on one side instead of the 0.08 mm of the die, which is very sporty even for viscous heat conducting paste. Liquid metal will run here before the BurnIn and the Kryonaut will not even find a hold. The appropriately selected heat-conducting paste must therefore play an important role and one is best served with a heat-conducting paste that is not too liquid and has a high thermal conductivity. Liquid metal should also reach to the corners, which naturally requires special care and does not always have to be target-oriented.

Kommentieren