Problem zone 2 – the curved package with strongly scattering height

Also a package always has tensions and certain height tolerances, so that is still completely normal. However, NVIDIA specifies up to 0.3 mm as a tolerance range here, which is also very high in comparison to Turing. We remember: there were water blocks of German premium manufacturers, who instead of the heat conduction pads only worked with heat conduction paste between the RAM modules and the cooler bottom. The excellent results are well known and have also been proven by my tests.

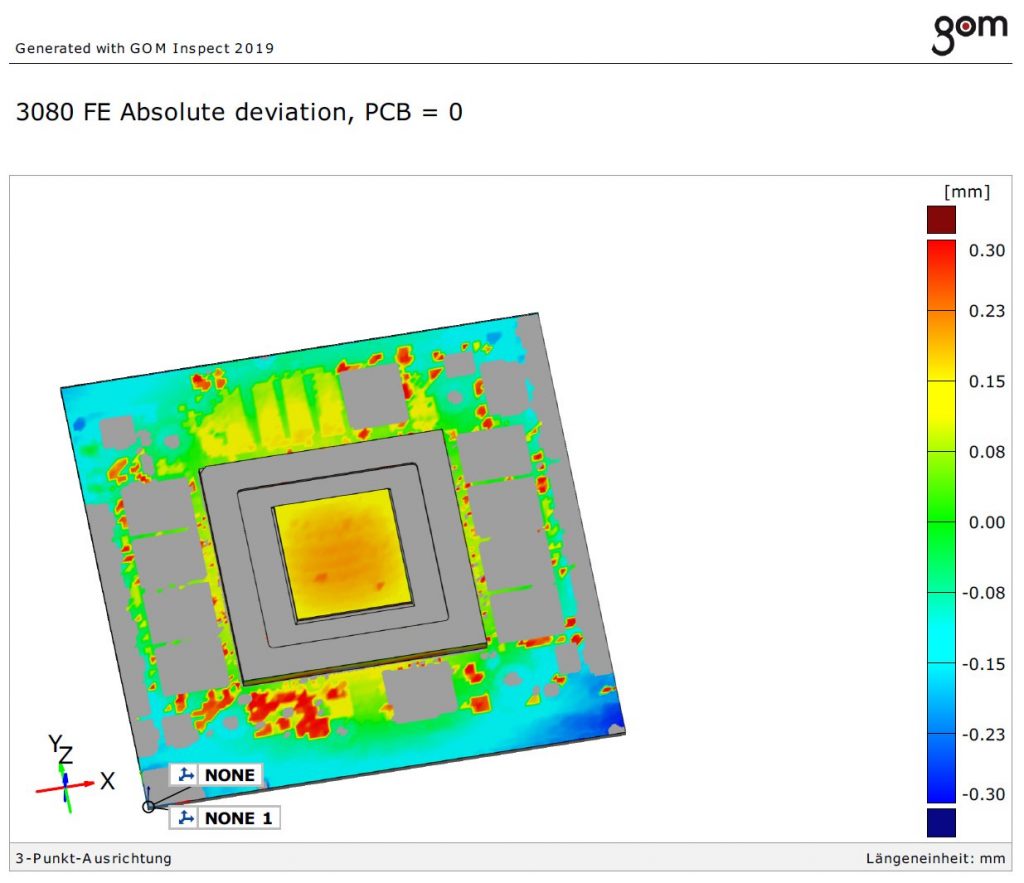

The following evaluation of the height differences shows a curvature and a simultaneous deviation of the actually measured heights from the 3D construction file, which is available as a standard specification and which I have put underneath as a direct comparison. You can also see very well the bending of the package and the underlying board of the graphic card. In this case, we see that even the board had to bend considerably due to the screwing in order to make contact at all. By the way, this is already irreversible after cooling down after a BurnIn.

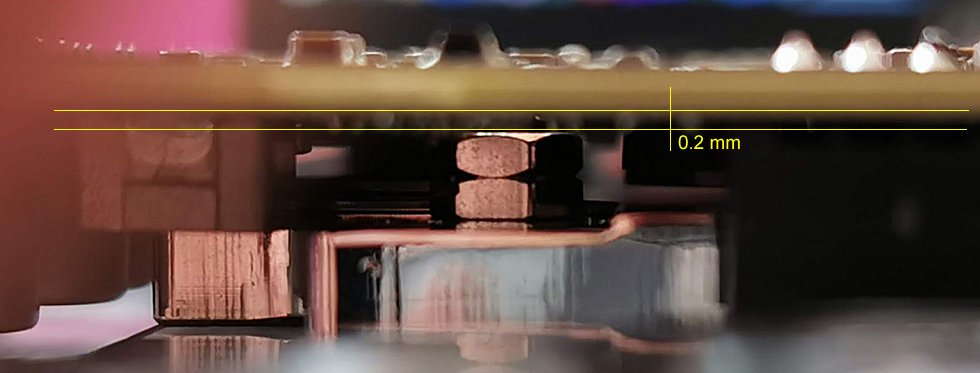

So I see a deviation of about 0.3 mm from the standard, which NVIDIA considers to be a tolerance limit, but still practical. These 0.3 mm don’t sound like much at first, but in practice you get a problem, because there are spacers between the cooler bottom (heatsink) and the board. The cooler manufacturer will of course first of all adhere to the official specifications for the package height. However, if the package is higher (within NVIDIA’s specs), the chip will hit the cooler too erly and the result is a gap between the board and the spacer:

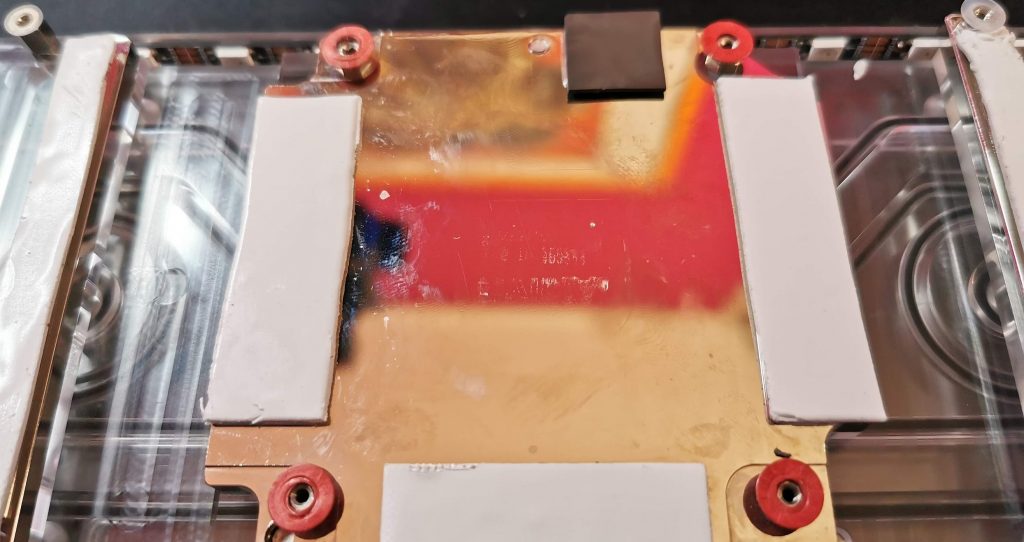

Now you could of course bend down the board with force by screwing it tight, but that’s not really smart. Everything will become all the more distorted and the surfaces will no longer be able to lie flat on top of each other (memory, MOSFETS etc.). That’s why I resorted to spacers in this case. How thick they had to be in this case is shown in the next figure, which however still reveals a problem. While the imprint of the die including the engraving can be seen as permanent traces in the copper base, the enclosed heat conducting pads did not have any contact at all.

Here one must now definitely switch to the next higher strength! And so the 0.5 mm pads suddenly become a 1 mm pad with twice the thermal resistance and the well-known consequences for cooling. But what is the cooler manufacturer supposed to do, because the next package may already look completely different? He would either have to add several thicknesses or switch to my beloved crumble pads in a solid thermal paste consistency. You can squeeze everything loose and without any nasty pressure on the components. By the way, NVIDIA also uses such pads itself, because you’ll know why.

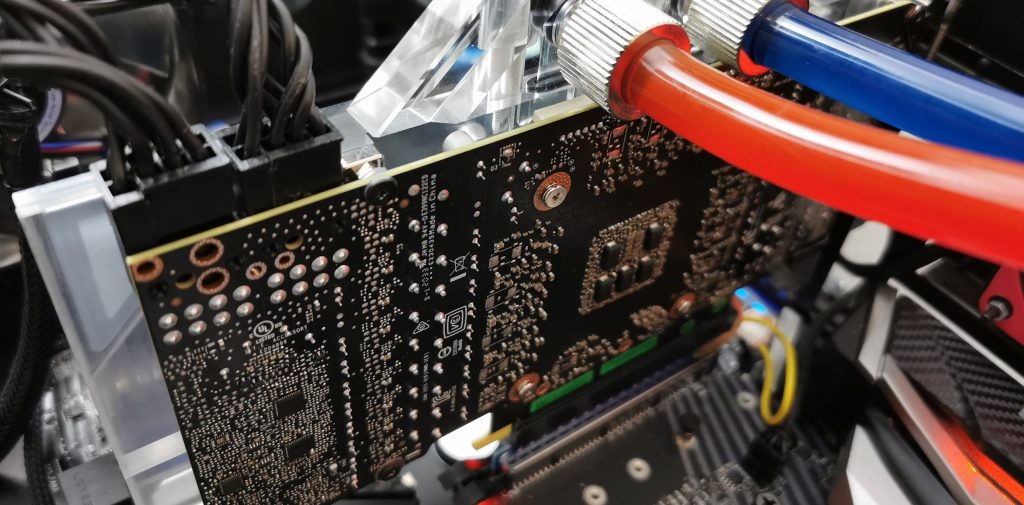

Once you have corrected and adjusted everything cleanly, the custom loop will also work. And no, this time it is not the supplier with the best gap dimensions who wins, but the one with the lowest standard deviation. So it becomes the GPU package lotto, where the cooler suppliers almost mutate into extras. That’s a pity, but if the toleration in the specs means it, then so be it.

Incidentally, the board partners have also found their very own approaches to solutions, which consist mainly of keeping distances as long as possible and using much thicker, viscous heat-conducting paste so as not to risk extreme bending. For the memory and the MOSFETS you just take thicker pads and the workaround is ready. This is anything but optimal, but at least it is practicable. It is not for me to evaluate this, but I would like to explicitly point out once again that there have been and still are significantly better gap dimensions. At most Vega was that extreme with the molded and unmoulded chips. But that was a completely different story.

Once again, in conclusion, the request to see these measurements as a decision support for the implementation of the cooling, if you want to build a custom water cooling system. NVIDIA is just a customer in the end and has to take what companies like Samsung and the packagers offers. But we Germans are bean counters and gap measurement fetishists of a different kind anyway, although it is always a pleasure when a car door closes with a gentle plop. Unfortunately, graphics cards are not cars.

Kommentieren