How to get the bow elegantly with the fat cable on the much too small plug has already been discussed long and wide. And as an outsider, you can criticize all sorts of things and conveniently blame the user, but that doesn’t solve the actual problem. It’s no secret that CableMod now offers suitable angle adapters for all installation directions, but few people know what’s really behind it and where several steps had to be taken to offer the most stable and secure product possible, which has taken all the criticisms into account.

Actually, I didn’t want to write anything about it yet, but sometimes you are quite happy when a plan works, because the parts go on sale already next week. The fact that I can already publish today’s pictures (factory leak style) (after having edited them a bit digitally for certain reasons) is also not entirely coincidental. Instead of being amused by the allegedly too stupid users, I continued to study the subject with Gabriele Gorla (NVIDIA) after the Zoom meeting and we also simulated all possible situations here in the lab quite elaborately and also questioned technical key data. And no, you don’t have to be that stupid as a user to sporadically reach the limits of the connector design.

But what is really essential about such a special angle plug? CableMod’s product already uses the new iteration of plugs and sockets, whose sense pins are slightly set back so that there is only an OK signal when the plug is engaged, i.e. inserted far enough. I think this is the most important feature, but it’s not everything. The sockets, if soldered perfectly, sit directly and cleanly on the adapter’s PCB. The only silly thing is that they move anyway due to external influences such as hanging and rigid, heavy cables. This is because the spring sleeves are soldered rigidly to the circuit board and are only relatively loose in the connector housing, which can be bent quite quickly. Then, with a bit of bad luck, you can again achieve gaps of 1 millimeter (++) and, above all, connections that are canted on one side.

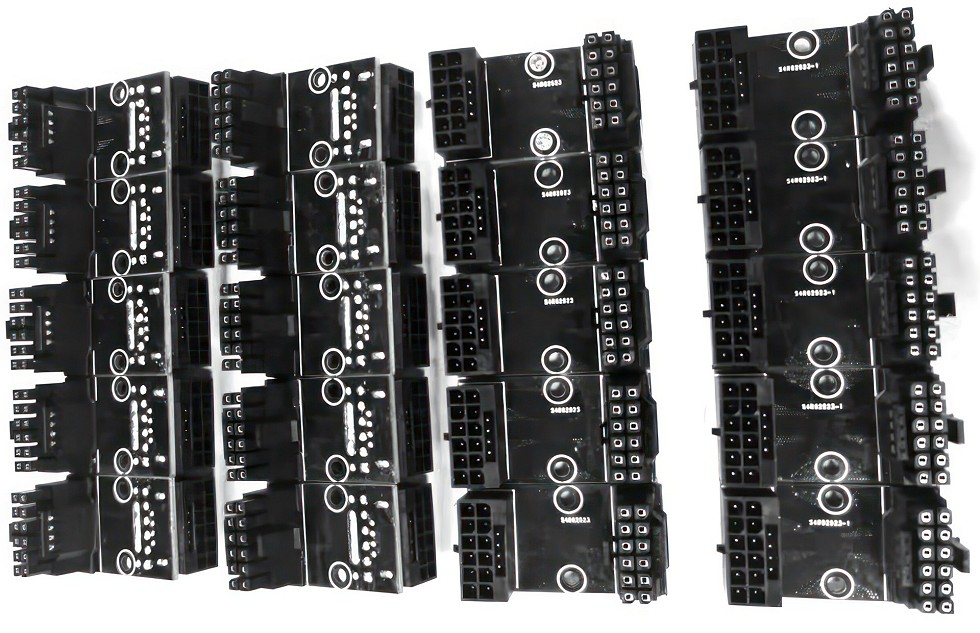

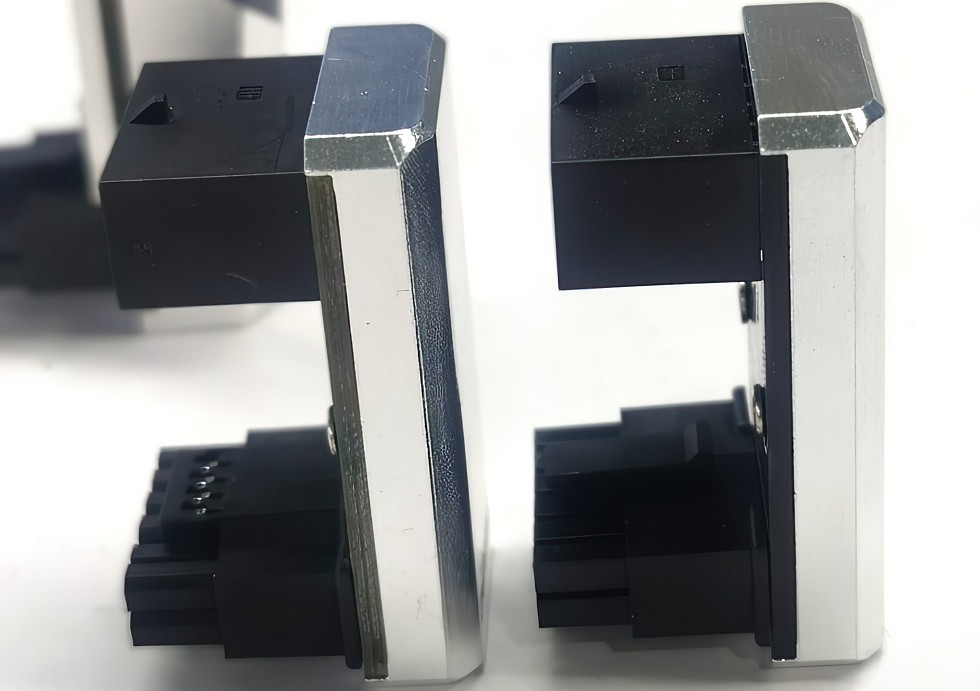

Without going into details now, because there are a few secrets after all: There are special adhesive connections that also bind the connector housing so tightly to the circuit board that the housing and sleeves always remain immobile and fixed on one level. The picture below shows what can happen with only a little pressure if you just solder on such a socket and do not fix it extra. You can’t do it that way. So this point is already taken care of, because this plug-in connection is now really safe. Especially since the components used were also selected to provide noticeable tactile and acoustic feedback (locking mechanism) in addition to the optimized sense pins.

Without going into details now, because there are a few secrets after all: There are special adhesive connections that also bind the connector housing so tightly to the circuit board that the housing and sleeves always remain immobile and fixed on one level. The picture below shows what can happen with only a little pressure if you just solder on such a socket and do not fix it extra. You can’t do it that way. So this point is already taken care of, because this plug-in connection is now really safe. Especially since the components used were also selected to provide noticeable tactile and acoustic feedback (locking mechanism) in addition to the optimized sense pins.

And as if all this was not enough, I also dared to analyze the circuit board and measured it several times. In the end, I was able to convince CableMod not to go with the normal 35 μm copper thickness boards (1 oz / ft2) and soldered-on voltage rails, but to go straight for the ones with double the copper thickness of 70 μm (2 oz / ft2). Since IPC-4562 specifies that the base copper (i.e. before processing) may be a maximum of 10% less than specified, it is not at least 31.31 µm, but twice that.

After the actual processing, a final copper thickness (IPC-A- 600J class 2) of at least 55.7 µm remains instead of the 24.9 µm of normal blanks. That would be a bit too thin in the long run and for overclocking fanatics. Safe is safe. And it has another advantage, because all six current-carrying lines are carried out separately up to the power supply unit, since this then knows best whether and how the whole thing is to be divided and fused again. It is enough to summarize only the mass.

Whether the lower cover of the illustrated variant of the 90° angle connector (first picture at the very top) then collides with the card or not depends on the respective model of the card. There will still be an alternative by means of coating, but this can probably also be finally clarified in the course of the day. The fact is, however, that it sometimes takes a little longer before you can give the okay with a clear conscience, but I think it was well worth it. The summary of what you should really look for when buying this or any other product:

- Adapted 12VHPWR connectors with optimized sense pins

- Permanently and firmly fixed sockets to prevent the movement of the contact sleeves

- Solid boards with at least 2 oz copper base thickness

- Additionally reinforced ground rail on the boards and no shorting of the 12 volt rails like in the NVIDIA adapter

That’s the end of this little preview and you now know a bit more about what I spend my free time with when something has really annoyed me. And no, there are no stupid users, but only products that were simply not thought through (and tested) to the end.

The connector from CableMod was modified under expert advice from me. CableMod is an advertising partner of igor’sLAB, no extra compensation was made for the service provided.

90 Antworten

Kommentar

Lade neue Kommentare

Mitglied

Urgestein

1

1

Veteran

1

Urgestein

Mitglied

1

Urgestein

Urgestein

1

Urgestein

1

Mitglied

Urgestein

Urgestein

Urgestein

Urgestein

Alle Kommentare lesen unter igor´sLAB Community →