There are many hobbies (or ways to waste money and especially time) and one of them is case modding. And it is not meant in today’s article the assembly of purchased RGB-lit components, but still real manual work and customization. And so today we will write about our experience with sandblasting and coating with Cerakote. We, that is CohesionModz and MS Design respectively. And in this little tutorial, we want to give you an insight into how we work and hope you like it and that it will help you with your own projects or spark your interest.

And what is it about today? Have you ever heard of Cerakote? Cerakote is a special ceramic coating that is applied to protect the work piece from corrosion, wear, and other outside influences. This coating is extremely durable, chemical resistant and offers a wide range of colors and finish options. Cerakote is a special type of coating used primarily on metal surfaces. It is a durable, high quality, heat resistant ceramic coating that was originally developed for use in the firearms industry, but is now used in many other applications. And that’s exactly what we’re going to do today….

Sandblasting is a technique in which abrasive particles are blasted at high pressure onto the surface of a material. This removes contaminants, rust, paint or coatings to create a clean surface for further processing. Sandblasting can use different types of abrasive media, such as sand, glass beads or corundum.

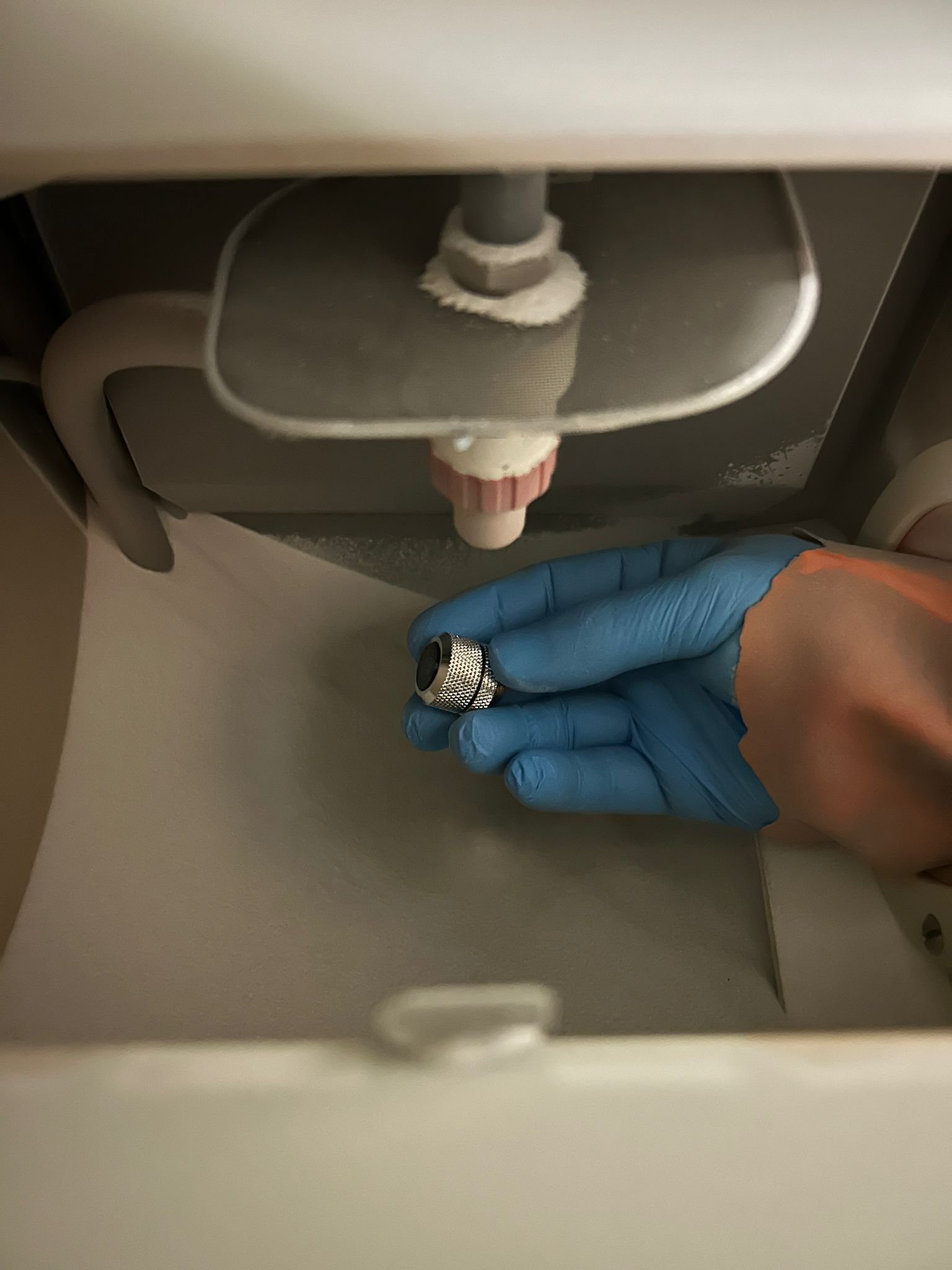

The first step in our process is to thoroughly clean the workpiece to ensure that the surface is free of dirt, oil or grease. The workpiece is then placed in a blast cabinet, which is used to control and shield the blasting process. The booth prevents abrasive particles from entering the environment and protects the operator from potential hazards. Once the workpiece is positioned in the blast cabinet, we select the appropriate abrasive media depending on the type of material and the desired result. We adjust the pressure and blast flow accordingly to evenly and effectively treat the surface. During the blasting process, the abrasive medium is blown onto the surface and effectively removes all contaminants.

So far, so unspectacular. But now it’s down to the nitty-gritty! Turn the page once, please…

Danke für die Spende

Du fandest, der Beitrag war interessant und möchtest uns unterstützen? Klasse!

Hier erfährst Du, wie: Hier spenden.

Hier kannst Du per PayPal spenden.

63 Antworten

Kommentar

Lade neue Kommentare

Urgestein

Urgestein

Urgestein

Urgestein

Urgestein

1

Urgestein

Veteran

Moderator

Moderator

Urgestein

Urgestein

1

Urgestein

1

Urgestein

Urgestein

1

Urgestein

Alle Kommentare lesen unter igor´sLAB Community →