Of course, we remember my last measurements on the radiators and the respective material analyses, some of which showed different things than the customer (or manufacturer) actually expected. Apart from the fact that alloys are often not 100% homogeneous, major deviations should of course not occur. Yes, trace elements below one wt% are more of a task for ICP-MS, which is also easily a size too big for my equipment. But anything above this magical percent is perfectly feasible. I have also received inquiries about this, so I would like to disclose this part of my work transparently.

You need to know that laser-induced breakdown spectroscopy (LIBS), which I also use, is an analytical technique that can be used to analyze elements in various materials. It is based on the emission of electromagnetic radiation (light) from a plasma generated by a high-intensity laser pulse. The emitted radiation is spectrally resolved and analyzed to determine the composition of the material under investigation. However, the accuracy of LIBS analyses depends on various factors, including, of course, the calibration of the equipment, the homogeneity of the sample and the general experimental conditions.

The accuracy of LIBS can be influenced by various aspects:

- Matrix effects:

Different materials can influence the plasma properties and therefore the intensity of the emitted spectra. However, this can be easily calibrated. - Surface properties and homogeneity of the sample:

Unevenness and inhomogeneities can lead to variations in the spectra. That’s why I use manual correction in addition to the automatic follow-up in case of doubt and also regularly check that the optics and laser match. Only if the material is exactly in the focus of the laser will an accurate measurement be possible. That’s why I use a test hole in a piece of steel before each session and then compare the optics and the actual drill hole (laser) - Experimental parameters:

Laser energy, focusing of the laser, atmosphere in which the plasma is generated (air, inert gas), and the delay time between laser pulse and spectrum acquisition can also influence the results. That is why I also try to regulate both the temperatures in the room and the humidity with normal effort (dehumidifier).

The calibration of LIBS

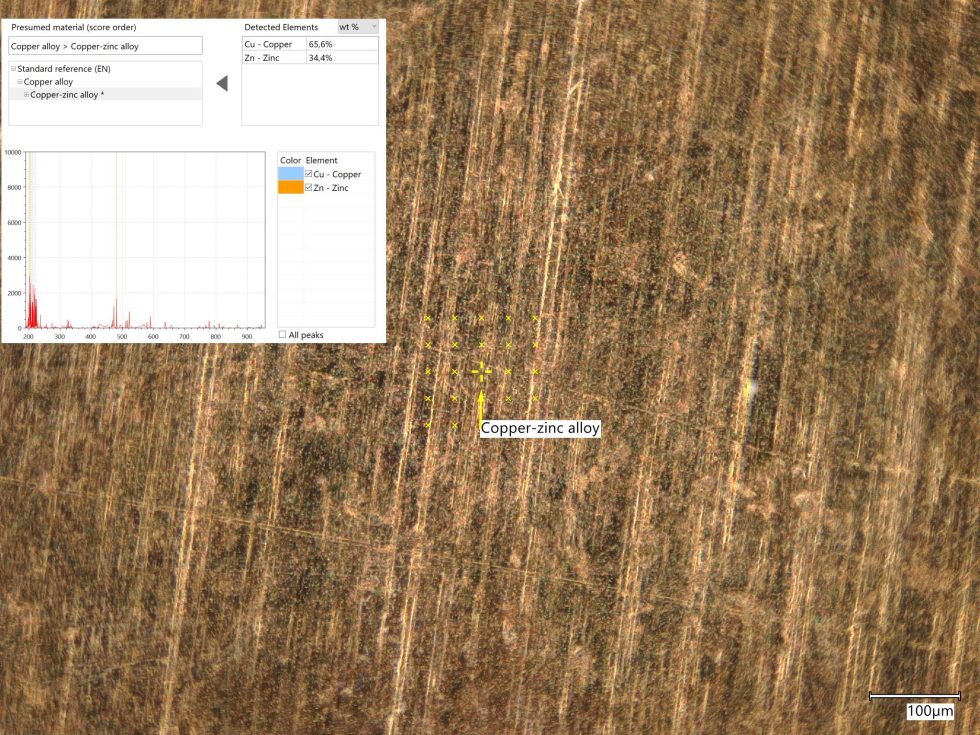

Accurate calibration is critical to the reliability of LIBS analysis. The most important point is the use of reference materials. For example, when measuring radiators, calibration is performed using standard samples of known composition (see image above). These standards should be at least approximately similar to the materials to be analyzed in terms of the matrix and the concentration range of the elements of interest. During calibration, the matrix of the reference material should also be similar to that of the analyte in order to minimize the so-called matrix effects.

The settings for the laser and the acquisition of the spectra should be optimized in order to obtain reproducible and meaningful spectra. This includes adjusting the laser energy, focusing the laser and selecting the delay time. Here I also rely on the many years of experience of colleagues who have been working with the adapted laser intensity for various materials for years. Multi-point calibration is also important, as the use of several reference materials over a wide concentration range can help to create a more reliable calibration curve. For example, brass with 10%, 35% and 50% zinc content (wt%) can be used to optimize the curves.

The use of advanced statistical methods and specialized software for data processing and analysis can improve the accuracy and reliability of the results, here I also rely on the experience of Keyence and the stored, very extensive databases, which I can even supplement myself. Anything in the range of less than one wt% can be considered sufficiently accurate, as there are an extremely large number of invoices that could still have a minimal influence on the result.

Summary and conclusion

Careful calibration and optimization of the LIBS technique is critical to the accuracy and reproducibility of the analysis. By taking the above factors into account, the reliability of LIBS analysis can be improved for a wide range of applications. It is therefore important to make this much effort at the start of the working day, otherwise, as always, if you measure a lot, you measure a lot of crap. In the example above, the measurements of the brass are fully within the desired tolerance range, which also shows that the previous radiator analyses are not wrong, but are quite accurate. I’m not the only one who should be able to live with that.

My thanks today also go to Wilbert Yuque, the CEO of Hardware Labs, who provided me with further calibration samples from German production and various information on the individual processes. This kind of transparency and support is exemplary and should definitely be mentioned.

|

|

|

11 Antworten

Kommentar

Lade neue Kommentare

Veteran

1

Urgestein

1

Urgestein

Urgestein

Urgestein

1

Urgestein

Urgestein

Urgestein

Alle Kommentare lesen unter igor´sLAB Community →