When you open a drawer searching for something and come across thermal paste that’s 20 years old, there are two possible reactions: throw it away or give it to me for testing. The kind dealer opted for the latter, as my curiosity is known to be the last to die. It’s almost like finding a can of soup from the era of the Deutsche Mark, but luckily, the expiration date isn’t visibly printed here. So, there’s no fear of knowingly upsetting your stomach. And that’s exactly where today’s test comes in – what’s not in it, can’t spoil. I just had to find out.

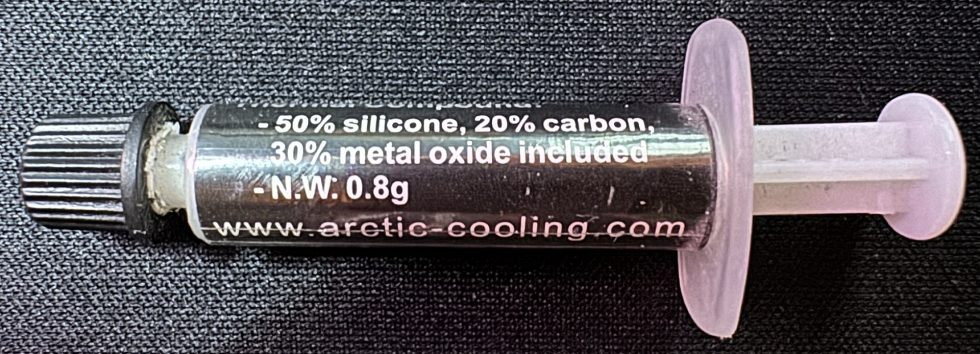

This might sound a bit cryptic? Well, yes, we also have to clarify the bit about the lie I mentioned in the title. Because one thing hasn’t changed in these 20 years: there’s lying in the specifications as if it were a competition. It was the same back then. You can see the tube in the picture above and notice that it was previously opened. But before I start testing today, I naturally studied the back of the tube. It claims to contain 50% silicone, 20% carbon, and 30% metal oxide.

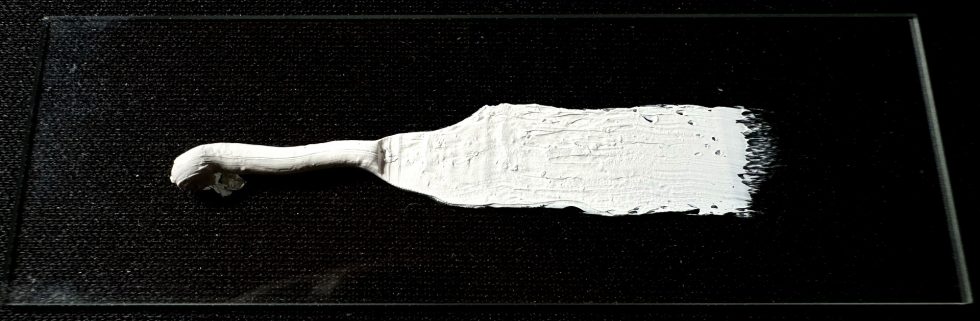

This naturally raises questions and piques curiosity. But can the paste still be squeezed out after 20 years? Yes, it could. And its consistency was still acceptable! So, I first pressed a small amount onto a slide and tested how well it could be spread. It went relatively well, even if the original might have been a bit more fluid. But it’s not rock hard either. I’m saving the rest for a 200-watt cooling test. But first, I check if the label is even accurate.

What should be inside

Using carbon as an additive in thermal paste was an innovative approach in heat dissipation technology, especially for high-performance computer systems. Carbon, especially in the form of microparticles, offers several advantages due to its unique properties. First, carbon is known for its excellent thermal conductivity. This property is crucial for thermal pastes as they must efficiently transfer heat from the CPU to the heatsink. Using carbon, these pastes can dissipate heat faster and more effectively than traditional pastes made from silicone or metal bases, at least in theory.

Another advantage of carbon is its chemical stability. Carbon-based thermal pastes are less likely to dry out or change consistency over time. This ensures lasting performance and reliability, which is especially important since reapplying paste on processors and other components can be time-consuming. Moreover, such carbon particles are electrically non-conductive, a significant plus for the safety of electronic components. This all sounds really good and innovative, but what’s really in the tube? The suspense builds.

Test setup

Before I analyze this, I want to briefly explain the term and the method behind it, because you can’t do without a background. LIBS stands for Laser Induced Breakdown Spectroscopy. The KEYENCE unit (EA300) shown in the picture for material analysis uses this method, which relies on a high-safety class 1 laser. In this process, the laser converts the surface of the object to be analyzed into a plasma state. Atoms and molecules of the material are ionized, causing them to emit light.

To measure and evaluate this emission, a high-resolution broadband spectrometer is used. This device can detect and analyze a wide spectrum of light colors, ranging from the deep ultraviolet to the near-infrared. This broadband capability allows for a comprehensive analysis of various elements contained in the material, as each element emits a specific light color or frequency. The design of the system used here is such that the microscope lenses are positioned on the same axis. This special arrangement optimizes the detection of elements in the measurement range. This concentrated and precise analysis enables the material analysis unit to provide accurate and reliable data on the composition of the examined material.

So much for the theory, but what happens with the data? The device I acquired is equipped with an extensive internal database containing thousands of material structures, which I can even continuously expand myself, for example, with compounds in thermal pastes. This resource allows the system to quickly predict the most likely material name based on the identified elements. To increase user-friendliness, the material data is organized in a hierarchical structure. This simplifies access to specific information like the specific material name, the generic name, and the description of the material. It’s kind of like EDX for dummies and really fast. And you don’t have to clean up afterwards.

In addition to the existing material structures, the database also has the ability to store and retrieve previous internal analysis results as needed. So, if similar foreign particles are recognized in later analyses, these previous results can serve as a reference. This feature not only facilitates the work of experienced users but also enables inexperienced users to identify materials in a simple and efficient manner. The combination of an extensive database, intuitive structuring, and reference options contributes to optimizing material identification for users of all levels of experience.

The compact and detachable unit houses specialized triple optics for viewing, laser, and spectroscopy. It is designed to offer a central laser transmission path with SLR optics near the lens, enabling high-performance focusing of plasma emission. Thanks to the combination of KEYENCE technologies, the components could be significantly reduced in size while still achieving high performance. The unit offers an innovative function for linking the field of view and focus.

This allows the microscope and laser lens to use the same field of view simply by being moved. This eliminates the need for alignment and focus adjustment during analysis. Swapping and attaching the most suitable lens is simple and convenient, regardless of the magnification level. The measurement is not entirely non-destructive, but it allows you to ablate layer by layer and remeasure the underlying areas. Pros and cons – it’s a balance.

But enough of the theory, because in the end, we want to know what’s really in this paste. After all, I’m not trying to sell you such a device (someone else already managed to do that to me), I’m just showing what’s possible with it. And that’s what you’ll see after turning the page!

50 Antworten

Kommentar

Lade neue Kommentare

Urgestein

1

Veteran

1

Urgestein

1

1

Urgestein

1

Urgestein

Urgestein

Urgestein

Urgestein

1

Urgestein

Moderator

Urgestein

Mitglied

Urgestein

Alle Kommentare lesen unter igor´sLAB Community →