To describe it in detail, otherwise the headline would have been too long: Today, we will use the field emission scanning electron microscope (FE-SEM) and energy dispersive X-ray spectroscopy (EDX) to analyze in more detail what is really inside one of the most popular (and also cheaper) thermal pastes in the form of the Arctic MX-4. The background is clear, because on the one hand I would like to know why exactly this product is so long-term stable and yet still cheap, and on the other hand the technical challenge was also quite interesting.

Of course my sincere thanks in the first place goes to one of my industry partners, where the applicable investigations and also the necessary technical preliminary work were realized selflessly and in their free time. Additionally there were the technical consulting and practical implementation of the tests, which are somewhat alien to the industry. Unfortunately, we cannot and are not allowed to offer you original pictures from the lab for understandable reasons of secrecy in such areas, but the product pictures will certainly make do anyway.

The way to the finished analysis was not so easy and we already had exciting discussions in the forum on the pre-published images of the scanning electron microscope (SEM), because some of our readers come from very related industry fields. However, we are not a science magazine here, but want to reach as broad a mass as possible and also convey some background knowledge without the reader despairing at the very first paragraph. That’s why I had to break the following down very far, but I hope that it will be more understandable this way and that the experts will forgive me in exchange.

Scanning Electron Microscope (SEM)

For the sake of simplicity, I’ll stick with SEM, although the German substitution REM (for scanning electron microscope) is, after all, synonymous. But since these abbreviations also appear in the product names, I’d better leave it at the original. I will leave aside the different ways of image generation like resting or scanning electron microscopy, as well as the realization via transmission (TEM, STEM) or backscattering (SEM), because we primarily rely on a reflection microscope and some of the methods may even overlap. Basically, it is a complex electron optics system in which a combination of electromagnetic and electrostatic lenses guide a fine electron beam as a raster over the rectangular object area to be tested. The final image is created by the synchronous registration of a triggered or alternated electron beam signal.

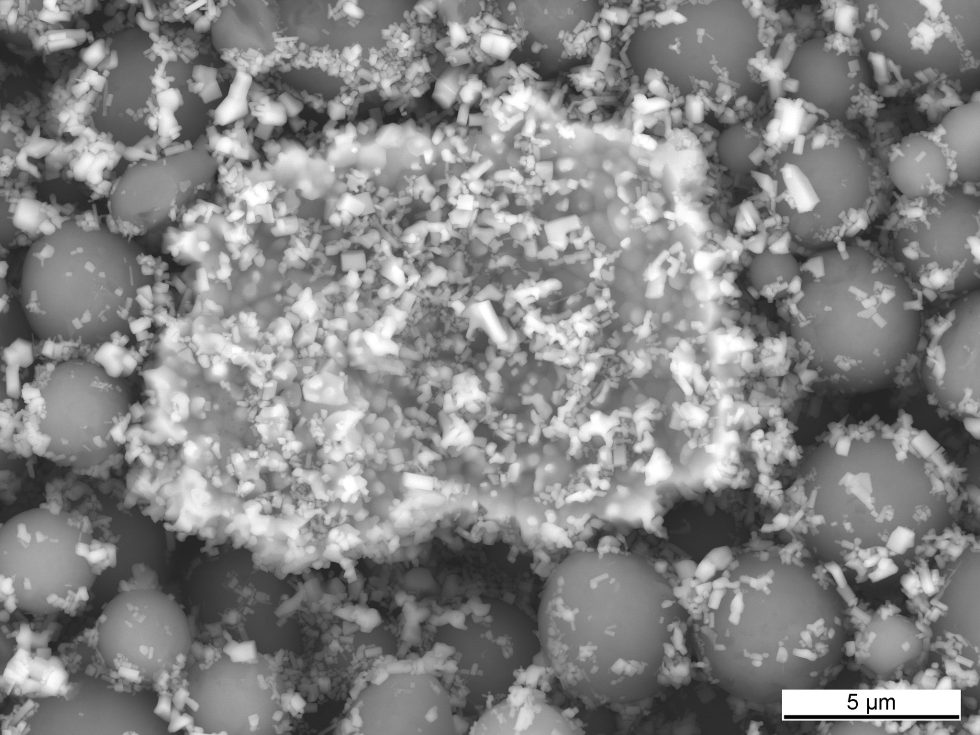

There are methods that rely primarily on the secondary electrons (SE), but we are mainly interested in the backscattered electrons (BE or BSE), whereby the image of the MX-4 above shows the BE very nicely contrasted. By way of explanation, these BEs are those electrons from the primary beam which are then elastically scattered from the hit atomic nuclei in the nanometer range below the object surface. The amount of backscattered electrons is in direct proportion to the average atomic number of the material under investigation.

Here in the picture we see the comparison of ZnO to Al. The heavier ZnO has much more electrons in the shells than Al. Thus, there is a greater probability of backscattering of primary electrons. As a result, more signals arrive at the detector. Thus, the backscatter signal already provides chemical information: the parts that appear brighter in the image have a higher average atomic number than the parts that appear darker. Otherwise, of course, the following also applies: Deeper areas of the special object appear darker, the closer ones bright, which leads to a plastic and quite contrasty image.

The measurable energy of these electrons is in the range of the irradiated primary electrons and the resulting image resolution (depending on the primary energy used) is in the micrometer range. With the help of electron backscatter diffraction (what a word), the crystallographic orientation of the crystals on a surface could also be used to determine certain material properties, but that would really be going a bit too far now.

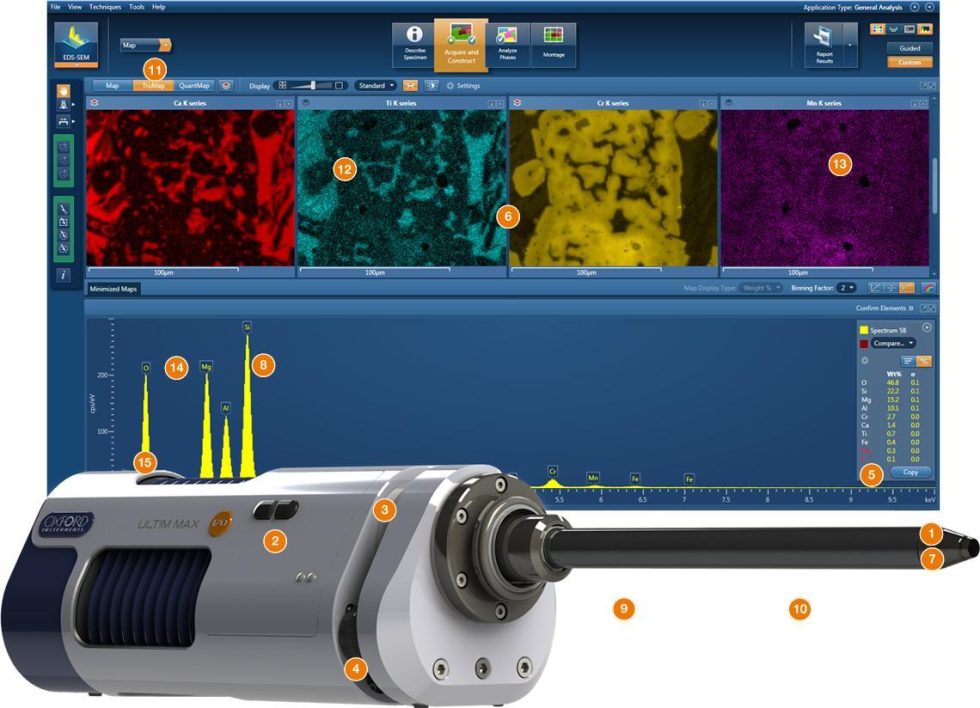

But we also need another tool for our final analysis. After all, we still have to enable the scanning electron microscope used to perform special chemical analyses on the surfaces in the micrometer range. For this purpose, we use energy dispersive X-ray analysis (EDX). By combining the SEM imaging raster process with EDX, it is also possible to capture beautiful elemental distribution images (top image). For EDX, the atoms are excited by an electron beam with a very specific energy, which in turn results in X-rays with an energy characteristic of the element in question. The resulting emission is therefore used to obtain information about the composition of the thermal paste.

Of course, the whole thing is now described very simplified, but I can not spare you completely either. Yet I can reassure you, because from the next page on, also because you have held out so bravely until here, it will be easier and also more entertaining. Promised.

32 Antworten

Kommentar

Lade neue Kommentare

Veteran

1

Veteran

Urgestein

Mitglied

1

Urgestein

1

Mitglied

Urgestein

Veteran

1

Urgestein

1

Urgestein

Mitglied

Urgestein

Urgestein

Mitglied

Alle Kommentare lesen unter igor´sLAB Community →