It’s the weekend, and I naturally have a lot to prepare for next week. However, I don’t want to leave you all alone on the side, so today I’ll show you what a “laser drilling” of 16 “laser shots” looks like with the LIBS equipment in the form of the VHX-7000 by Keyence. The object of my curiosity today is a CPU that you could briefly find on eBay from Alternate. And since I have pretty much no fear of anything, this piece had to undergo laser treatment today. And, of course, be examined under a 2000x microscope. There will be more information in the launch article soon, but for now, I can give you a little teaser.

Many have asked me what and how much I actually vaporize with each laser shot. To be honest, I didn’t know exactly myself! Yes, the diameter of the crater and especially its depth depend on the material, but you can still gather some information. As an example, I’m now shooting through the package of the CPU that shall not be named and looking for a spot where there’s a thicker copper trace beneath the green coating. Just fiber optic stuff would be boring. In the top left, we see a point-shaped recess in the package’s coating, and in the middle, the lunar landscape I created with the impact crater.

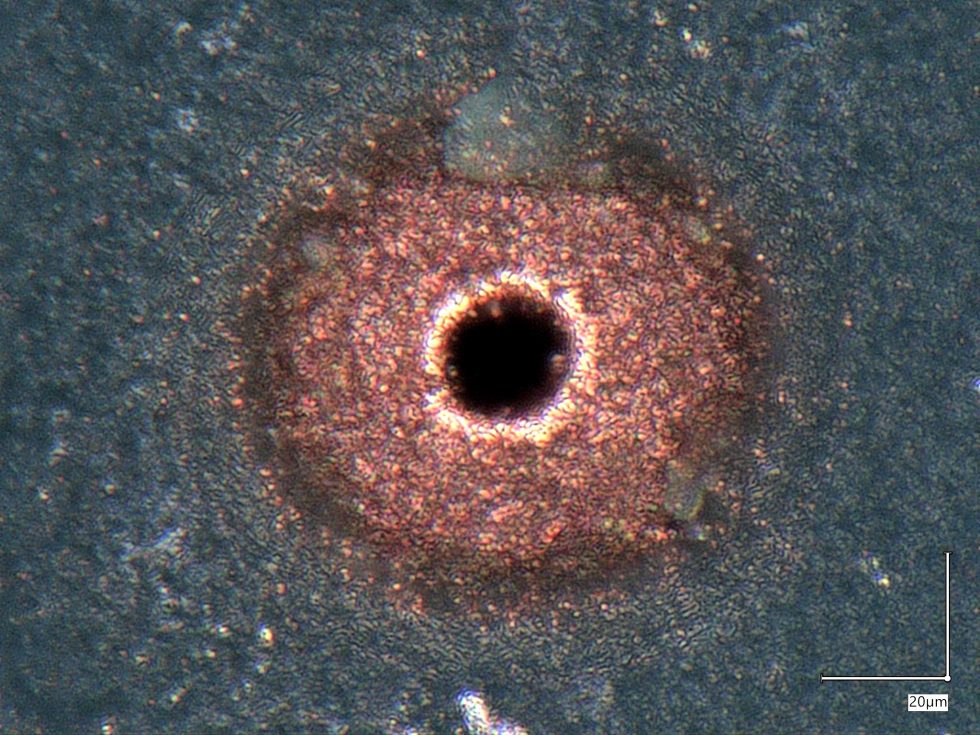

And now? Let’s zoom in and see: The layers are not as homogeneous as one might think with the naked eye. We can see this clearly, especially at a 2000x magnification. Okay, we are still on the horizontal plane and could estimate the individual dimensions at least with the help of the scale (or measure them with the software). But there’s probably an even better way…

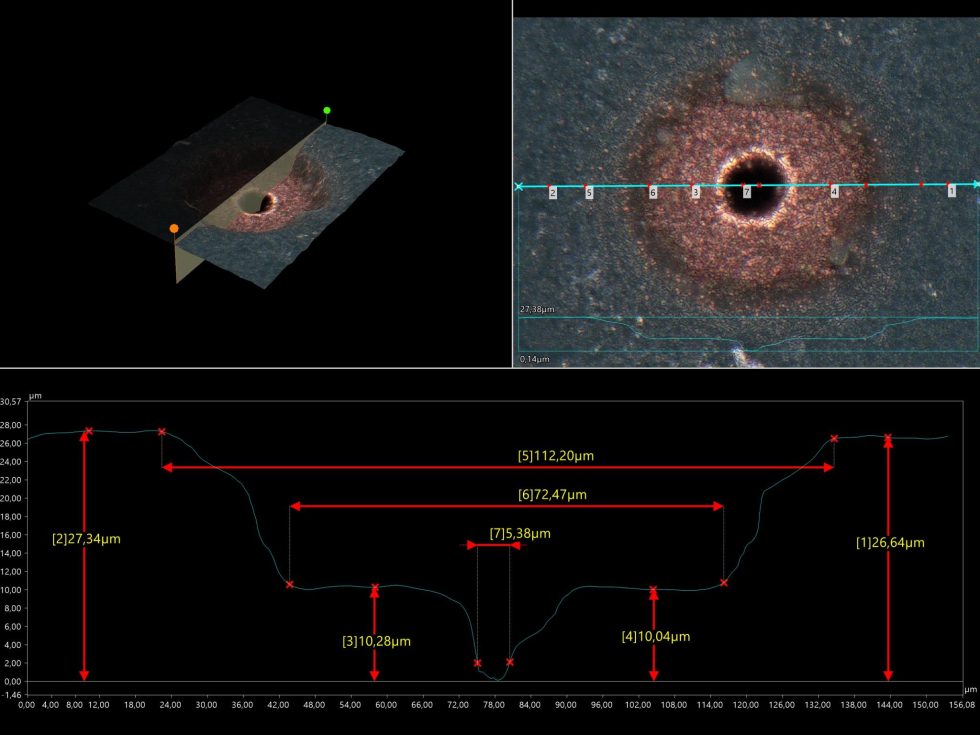

Now, let’s take a look at my borehole in 3D! Well, we won’t find crude oil here, but we can gain some insights. At the bottom center, we see that the actual laser beam creates a hole with a diameter of about 5 μm in the copper trace, and the rest is vaporized repeatedly, especially since there can also be scattering. The diameter in the hole of the less resistant coating is, of course, significantly larger, at slightly over 0.1 mm.

We see that such an impact is not without losses, and you have to be careful not to damage sensitive components. But I can freely choose both the laser intensity and the type of measurement (drilling or surface matrix). It takes a bit of experience, but you learn quickly where the limits are. Which brings us to the end again, as I now have to build tons of chart graphics and, of course, label everything properly. We’ll all be wiser by Tuesday afternoon. Or as my family doctor would write on the prescription with a laugh: raptors cancer terminalis.

15 Antworten

Kommentar

Lade neue Kommentare

Veteran

Urgestein

1

Veteran

Urgestein

Urgestein

Urgestein

1

Urgestein

1

Urgestein

1

Neuling

1

Mitglied

Alle Kommentare lesen unter igor´sLAB Community →