nuPro X-3000 RC and nuPro X-4000 RC Teardown

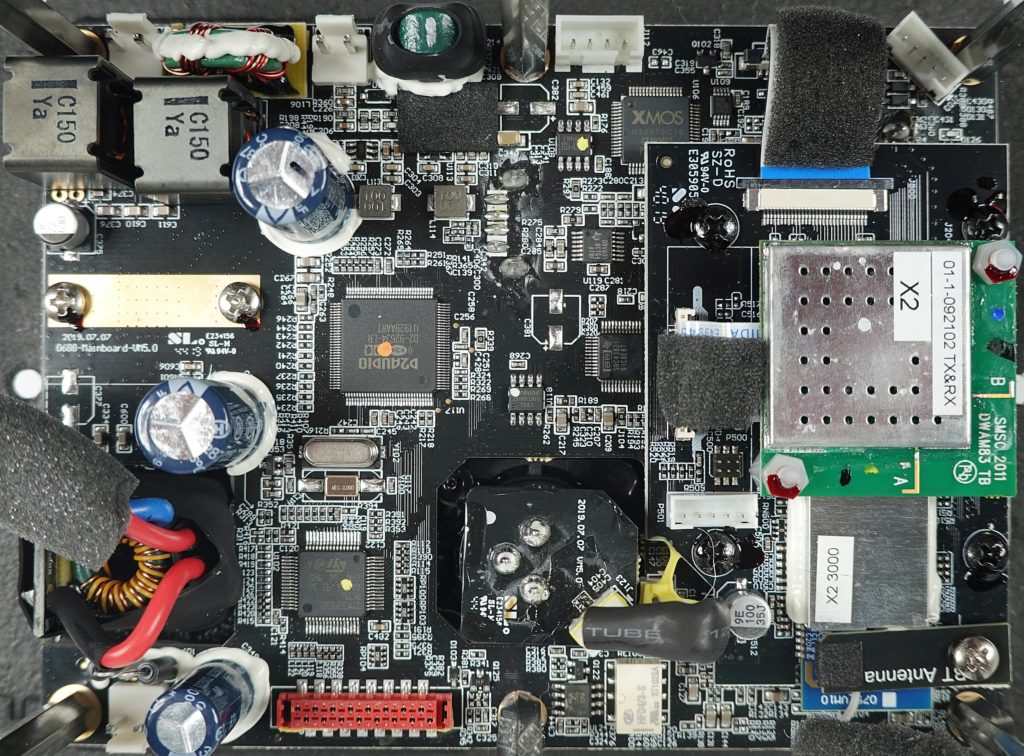

Since both models are completely the same except for invisible small differences in supply voltage and programming of the active crossover, I use the X-3000 RC as an example for both models. To get inside, I first unscrew the whole unit from the body and am glad that they don’t use the usual cross-slits. The compact unit is relatively easy to remove and the cables can also be pulled off safely.

Only the BT antenna buried somewhat haphazardly in the endless clouds of white insulation wool with the adhesive surfaces seems somewhat helplessly placed, but it works. The body cuts a solidly finished figure, even on the inside. We also see here the rear side of the very long-throw mid/bass driver including the magnet and the port in the middle. The cooling of the winding should not be a problem.

By the way, the tweeter is located exactly below the bass reflex tube made of impregnated hardboard, whose length of approx. 17 cm gross (including the glued-on plastic baffles) indicates a rather low tuning. The interior insulation is quite compact, so that one can also assume a decent damping here.

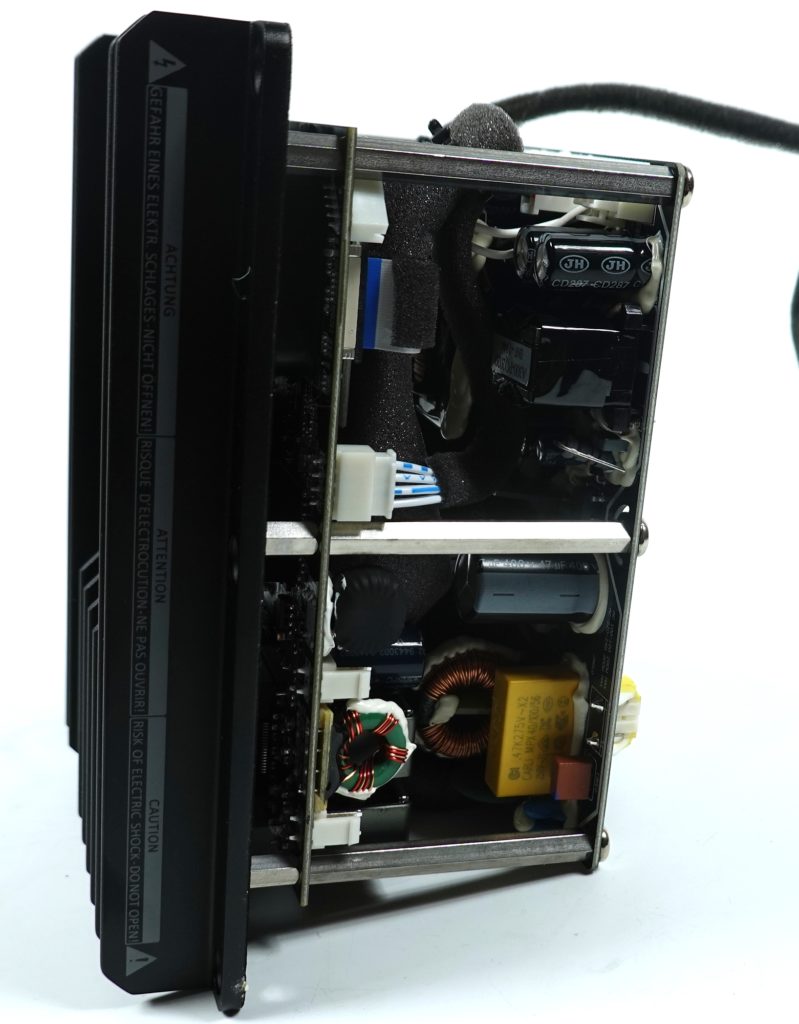

The removable unit carries the audio board including the power amplifiers cooled via the mounting plate in the lower board layer. Above this, the power supply board is screwed overhead with spacers. By the way, the arrangement of the main transformer is quite cleverly chosen to avoid useless radiation into the sensitive areas of the audio board.

The power supply

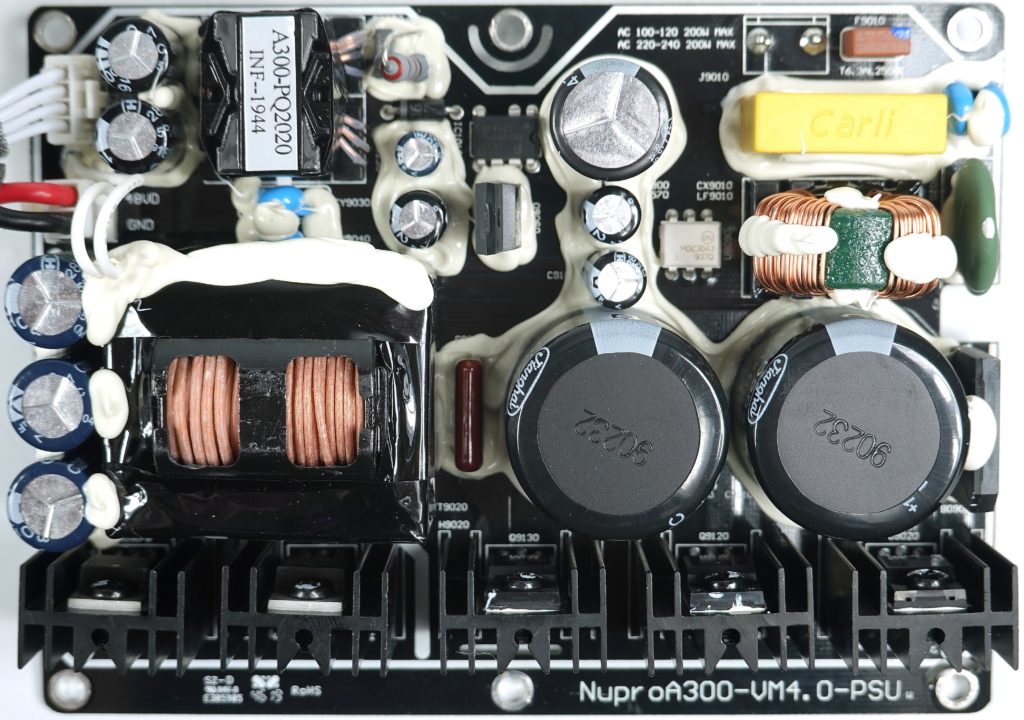

Power supplies are often underestimated or simply disregarded, yet they are incredibly important, especially for ensuring a constant nominal power, undistorted, short-term pulse peaks and a proper external voltage margin. The single layer board is manufactured by SHENZHEN SHENZE ELECTRONIC CO. LTD and is identical to the circuit board of the nuPro A300. The parts are then assembled by the contract manufacturer. Maximum power is a generous 200 watts, though about 150 to 180 watts should be typical. This is also in harmony with the components used, because with a stated nominal power of 150 watts per speaker (X-3000 RC) or 180 watts (X-4000 RC) plus the usual losses and all the other peripherals, you quickly get into these ranges.

A simple comparison measurement on the primary and secondary side showed an efficiency of up to 95% for the entire construction, whereby one must include the second, small power supply unit for the fuss and the power balancing. Here, in normal operation, a few more watts should be added. However, what benefits efficiency is this bifurcation in any case. Here, such an effort is always worthwhile, which, moreover, goes beyond mere standby switching. The soldering quality of the whole board is decent.

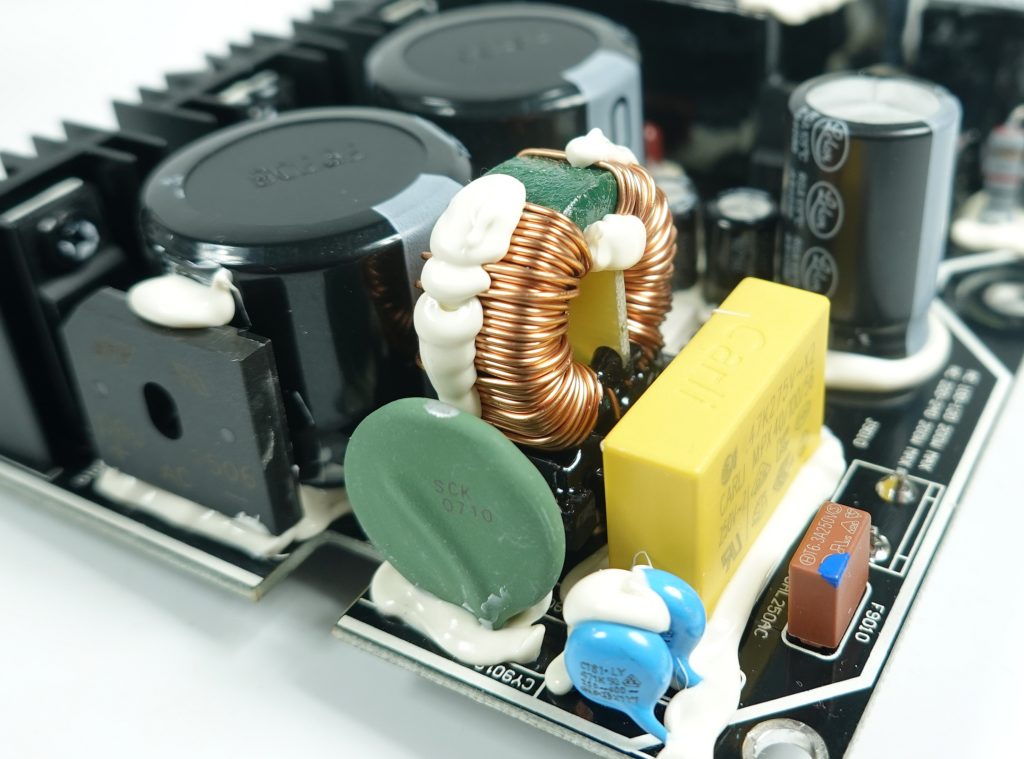

Most of the time you don’t even want to know what is fed into a power supply, because the mains voltage rarely comes out of the socket alone and clean. At the latest when further consumers are connected to a distributor, it can quickly become disgusting. After the physical on/off switch, the power supply is equipped with a proper input filtering and smoothing against spikes and unwanted HF radiation, including a MOV as overvoltage protection. What is visually missing is a fuse on the board and a real supervisor chip on the voltage rails of the secondary side including shunts in case of a short circuit. The two decent primary electrolytic capacitors each have a capacitance of a whopping 680 µF, which can even make up for short voltage drops. I’ll get to the manufacturer in a minute.

Despite the high capacity, the inrush current per box is still within tolerable limits. However, I would strongly advise against hanging both speakers and perhaps a subwoofer behind a shared wireless socket (you don’t do that anyway). If you have very sensitive 16 A fuses in the switch box, you may find yourself in the dark more quickly than you would like. But that’s the problem with all switching power supplies.

Both power supplies function as classic switching power supplies, whereby the detour via a more complex DC-DC power supply for the different partial voltages of the consumers is not necessary at all, because they are two separate power supplies from the start. The MOC3043 from On Semiconductor is the usual opto-coupler on the larger power supply, which is already one of the better ones. The TNY280PN is also an appropriate AC/DC converter from Power Integrations. It fits.

The complete capacitor assembly of the electrolytics relies on very practical 105 °C models from Jianghai, both on the secondary side (in the picture below) and the primary side, as well as the voltage conversion. With almost 1500 µF on the secondary side you create a decent buffer for power peaks. So it’s not a “hard” power supply that sticks to the limit like a cutter, but rather “soft”. These designated Low Impedance and High Ripple Current capacitors are best suited to last a few years.

And who now guesses the manufacturer on a Chinese junk manufacturer, is already wrong. Jianghai is one of the oldest Chinese manufacturers and emerged from a former supplier of the People’s Army. In addition, the entire capacitor production has now been purchased from Hitachi. So in the end you have Hitachi quality at a fair price. The parts really don’t have to hide behind those from Chemicon.

The audio board

This multi-layer board comes as a motherboard from SHEN ZHEN SUN & LYNN CIRCUITS CO LTD and also here the assembly and soldering quality at the final manufacturer are completely ok. The attached radio module comes as a single layer board again from the power supply manufacturer. Almost centrally located is the heart of the entire concept: the D2-92634 D2Audio from Renesas.

This D2-3(S) Audio SoC acts as a Digital Sound Processor (DSP) and is basically the girl for everything. The system-on-chip (SoC) built in here provides efficient and configurable audio signal path processing including equalization, dynamic range compression, mixing and filtering as well as a fully configurable high level programming interface. The integrated PWM engine supports programmable and dynamic control of audio output, noise shaping, an embedded asynchronous sample rate converter, and directly controls power stages with SNR values >110 dB and a THD+N of <0,01 %.

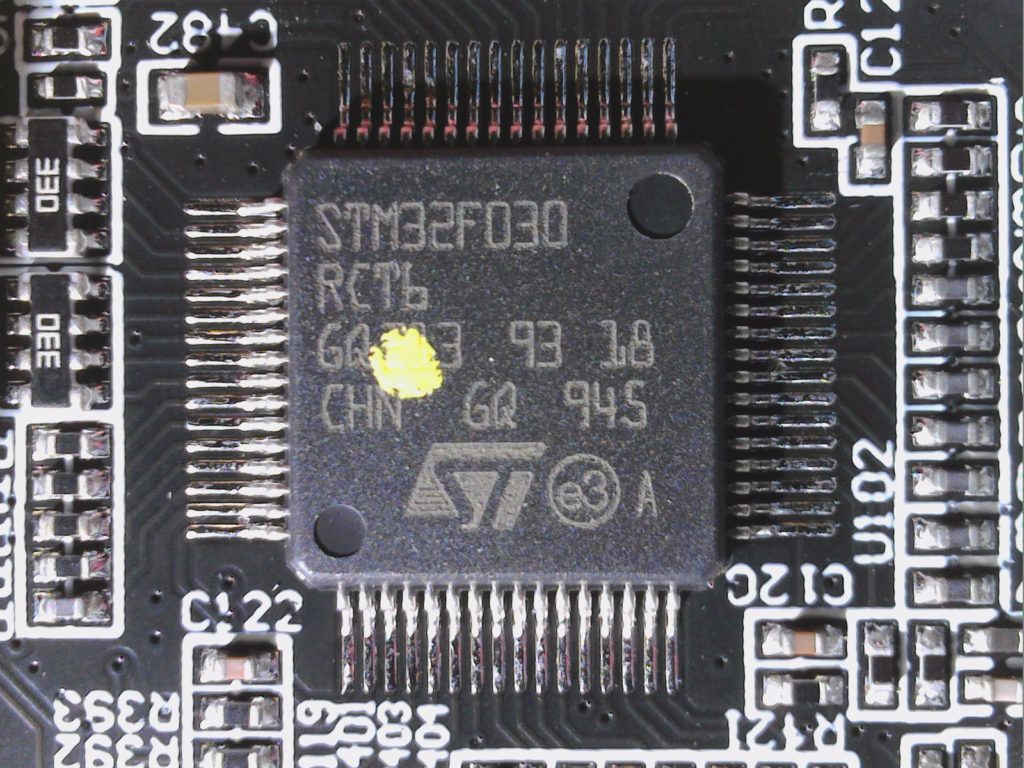

In addition, the active crossover implemented with this DSP creates an almost ideal phase alignment of high and mid/bass frequencies for both models and synchronizes the critical group delay of the drivers in multi-way systems. There you should be able to locate the difference in programming for the nuPro X-3000 RC and X-4000 RC. This should fundamentally improve the bounce and impulse behaviour, which altogether allows a very precise playing style for both speakers, which can also be heard. In addition, a relatively fast 32-bit Arm Cortex CPU with up to 48 MHz clock is used as the MCU for process handling. The firmware is stored in a separate BIOS chip.

In addition, the active crossover implemented with this DSP creates an almost ideal phase alignment of high and mid/bass frequencies for both models and synchronizes the critical group delay of the drivers in multi-way systems. There you should be able to locate the difference in programming for the nuPro X-3000 RC and X-4000 RC. This should fundamentally improve the bounce and impulse behaviour, which altogether allows a very precise playing style for both speakers, which can also be heard. In addition, a relatively fast 32-bit Arm Cortex CPU with up to 48 MHz clock is used as the MCU for process handling. The firmware is stored in a separate BIOS chip.

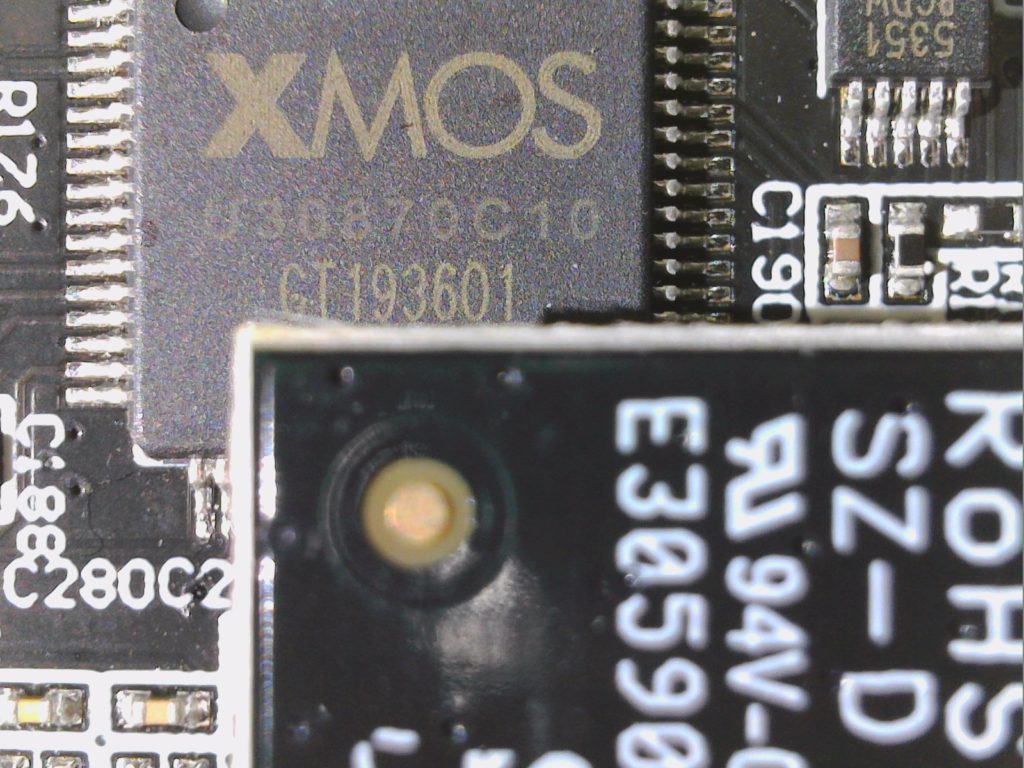

The XU208-128-TQ64 (XMOS U30870c10) is a multi-core microcontroller from the xCORE-200 series that is popular in high-quality circuits. Up to 32-channel USB and networked audio applications could be realized this way. This is also supported by the integrated High Speed USB 2.0 PHY and 16 logical cores, which can deliver deterministic and responsive processing performance of up to 2000 MIPS. Taking advantage of the flexible programmability of the xCORE-200 architecture, a maximum of 8 input and 8 output audio channels can be streamed simultaneously at up to 192 kHz. That’s quite enough.

The power amplifier is a so-called UCD (Universal Class D) switching amplifier, which significantly improves the performance of an analogue switching amplifier. Using this technology from the 1980s, a cleaner signal processing is achieved than with conventional Class D bridge circuits and various upstream converters and drivers. The pulse-width modulated signal (PWM, 384 KHz clock), which is distributed by the DSP to the individual branches in real time, is sent in digital form to the parallel-connected PWM output bridges without any detours. Low noise and low jitter are then the reward of this trick. In order to get a phase-stable behaviour and low TIM and THD error values, a DC filtering in the low, single-digit Hertz range is used.

The power amplifier chips are thermally connected to the base plate via an intermediate piece, which also serves as a universal fin heat sink. The used pads are apparently completely sufficient, because even a full load test of several hours didn’t lead to a breakdown, even if the circuit board and the hard disk got quite warm then.

Interim summary

The entire electrical and electronic side is well stocked on both models. The D2Audio DSP is currently hard to beat for this price range, the MCU used is purpose-built and the XMOS chip is almost a bit over the top. All the peripherals with wireless connection and connectivity and the IR module are fine. The direct A/D conversion of the analogue inputs without further analogue signal processing and the prompt transfer to the DSP ecosystem is well solved, but for most older phono devices you still need a preamplifier. The power supply fits the price range and does exactly what is expected of it.

A small side note on the assessment of the soldering quality, which of course can only be a snapshot and does not replace a real 10-year long-term test with daily vibrations. I checked the surfaces and edges under the microscope, which affects both the reflow components and the solder joints and surfaces from the wave solder bath. In addition, the soldering points of the cables and connections, as well as the search for possible manual rework and the cleaning of the boards or soldering points. All these points make me quite optimistic that the whole thing will last a little longer.

35 Antworten

Kommentar

Lade neue Kommentare

Veteran

1

Neuling

Mitglied

Mitglied

Mitglied

Neuling

1

1

Mitglied

Mitglied

Mitglied

Mitglied

1

Veteran

1

Mitglied

Mitglied

Mitglied

Alle Kommentare lesen unter igor´sLAB Community →