Cooling concept and implementation

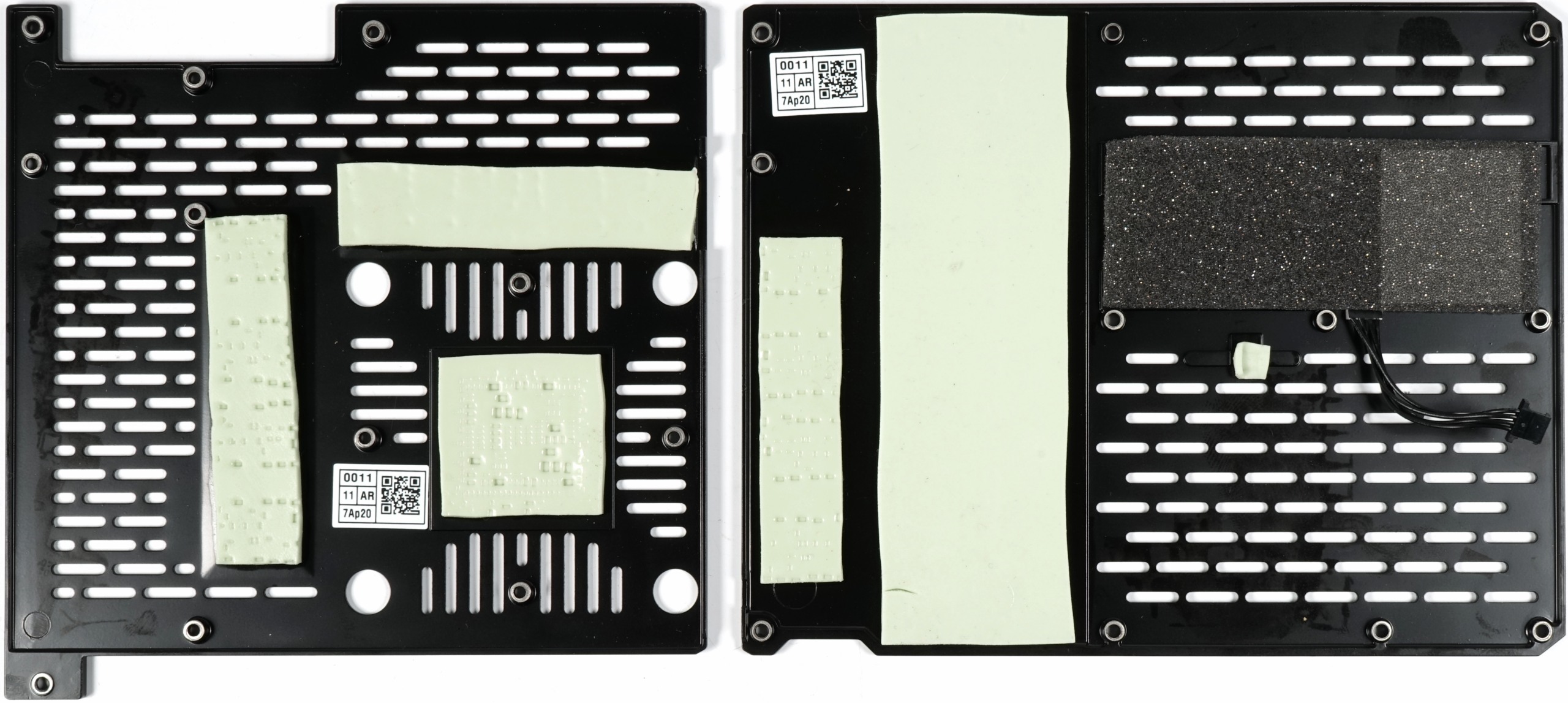

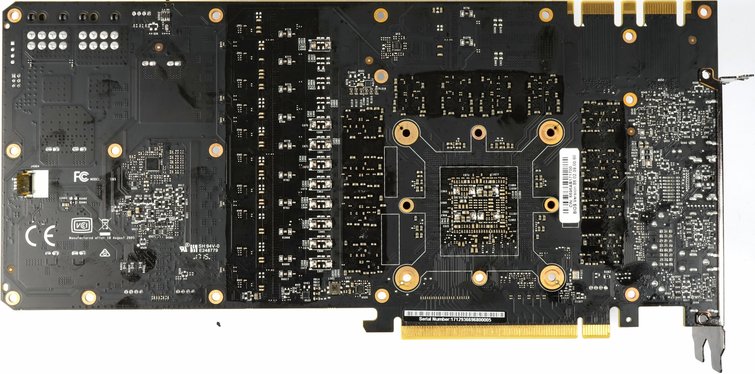

The back of the board is conspicuously inconspicuous and shows the dark traces of the glued-on thermal pads between the backplate and the board. Which would have made us look elegant at the cooling.

The two-part backplate used without internally glued foil is passively used for cooling and, of course, for optics. It also fixes the sandwich structure with the extra cooling plate between the board and the actual lamella heatsink.

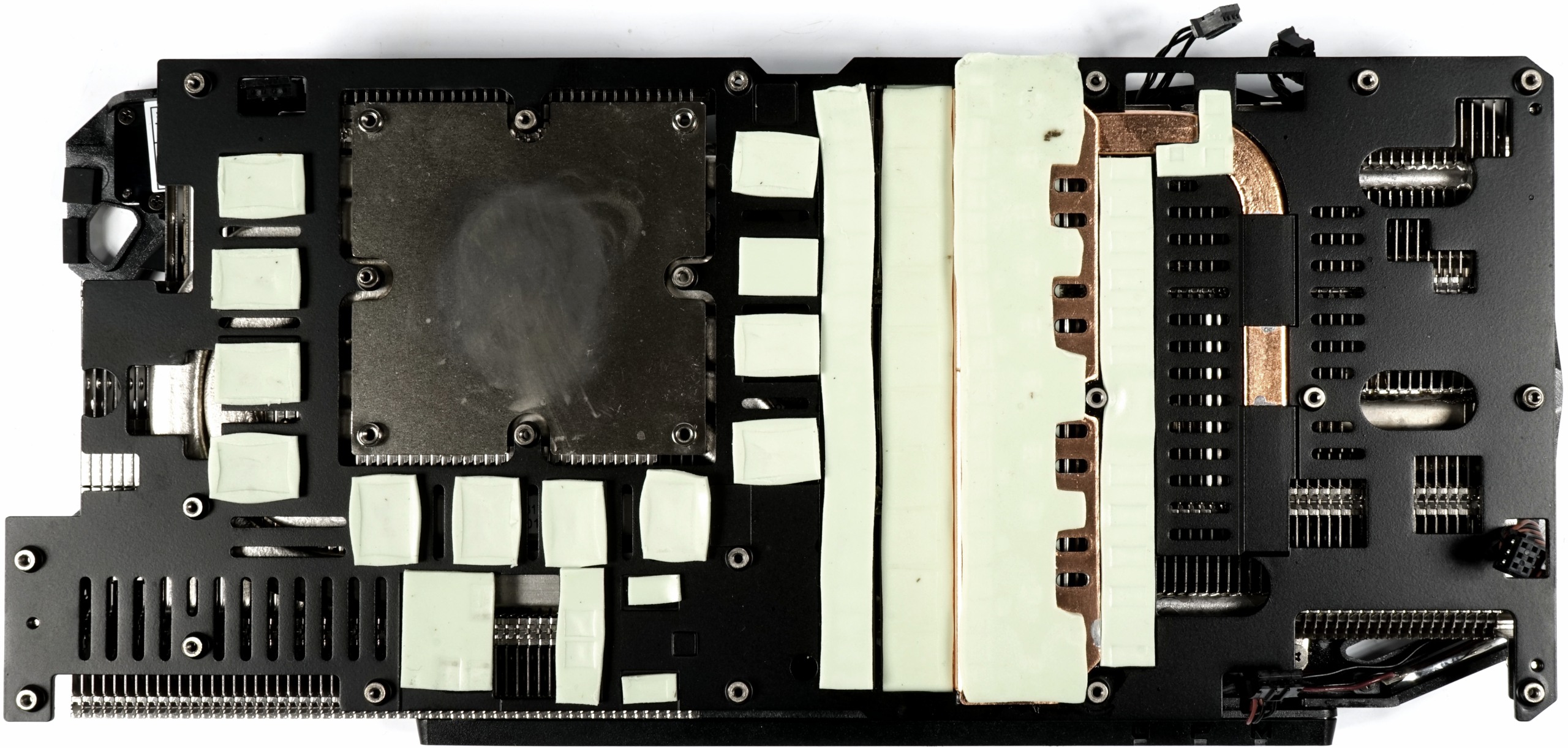

We already mentioned that there is no heat sink integrated in the main cooler for the voltage converters. We also know that the VR had to be spatially de-wired due to the many control loops. Let us therefore first consider what now sits directly on the board. The number of thermal pads is enormous and we deeply regret not having bought shares of the relevant pad manufacturers as early as the summer of 2016. EVGA is now a real major customer, who is now quite adept at handling the helpful pads.

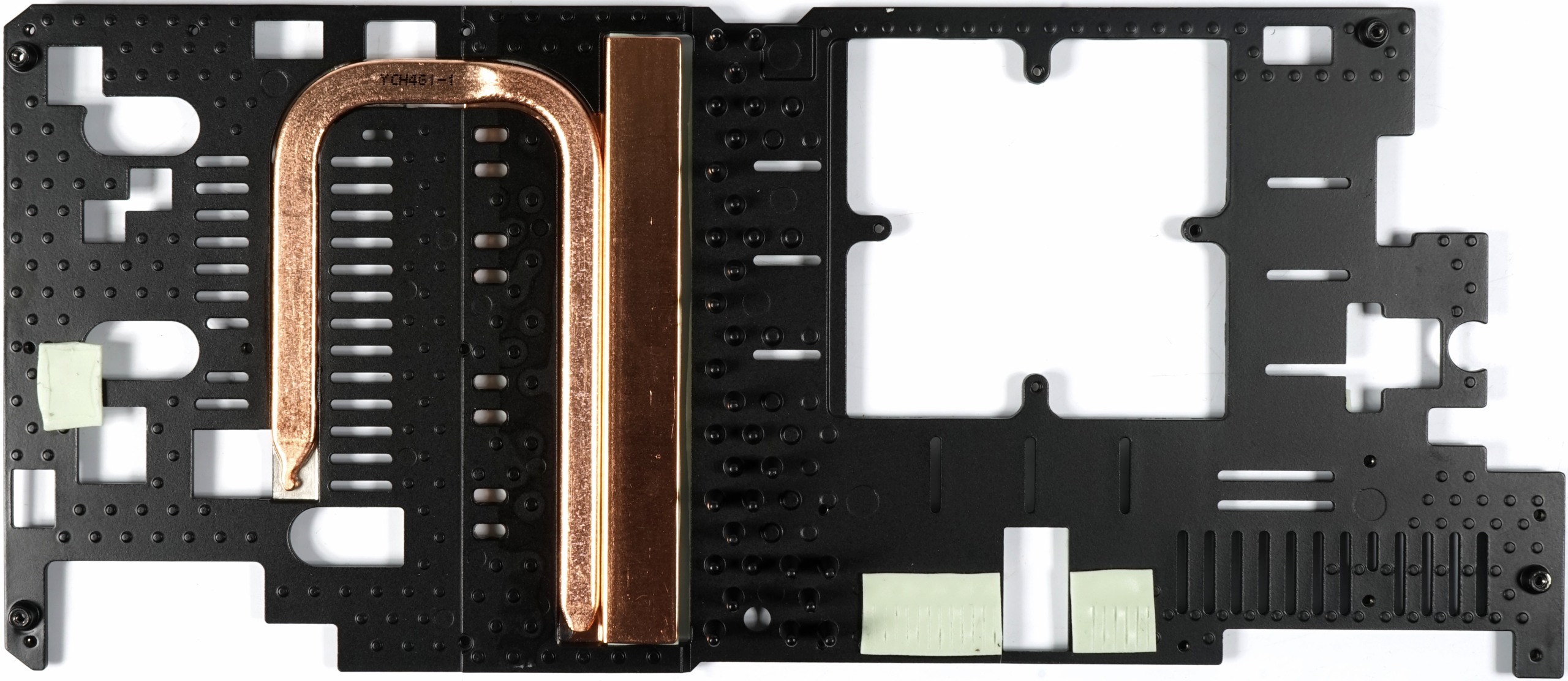

With the exception of the GPU and the GPU heatsink, everything is cooled by the so-called "sandwich" cooling plate, whether the memory modules, the components of the GPU and memory voltage converters (MOSFETs, coils) or various other hotspots. We also see the heatpipe with VRM heatsink, which uses a pad on one side to contact the components and the radiator fins on the back. The heatpipe equalizes the hotspot a bit and has a further contact with the slats of the top via pad. An experiment without a connected heatpipe (we had the pad removed) resulted in a temperature up to a good 3 Kelvin higher of the mean MOSFETs.

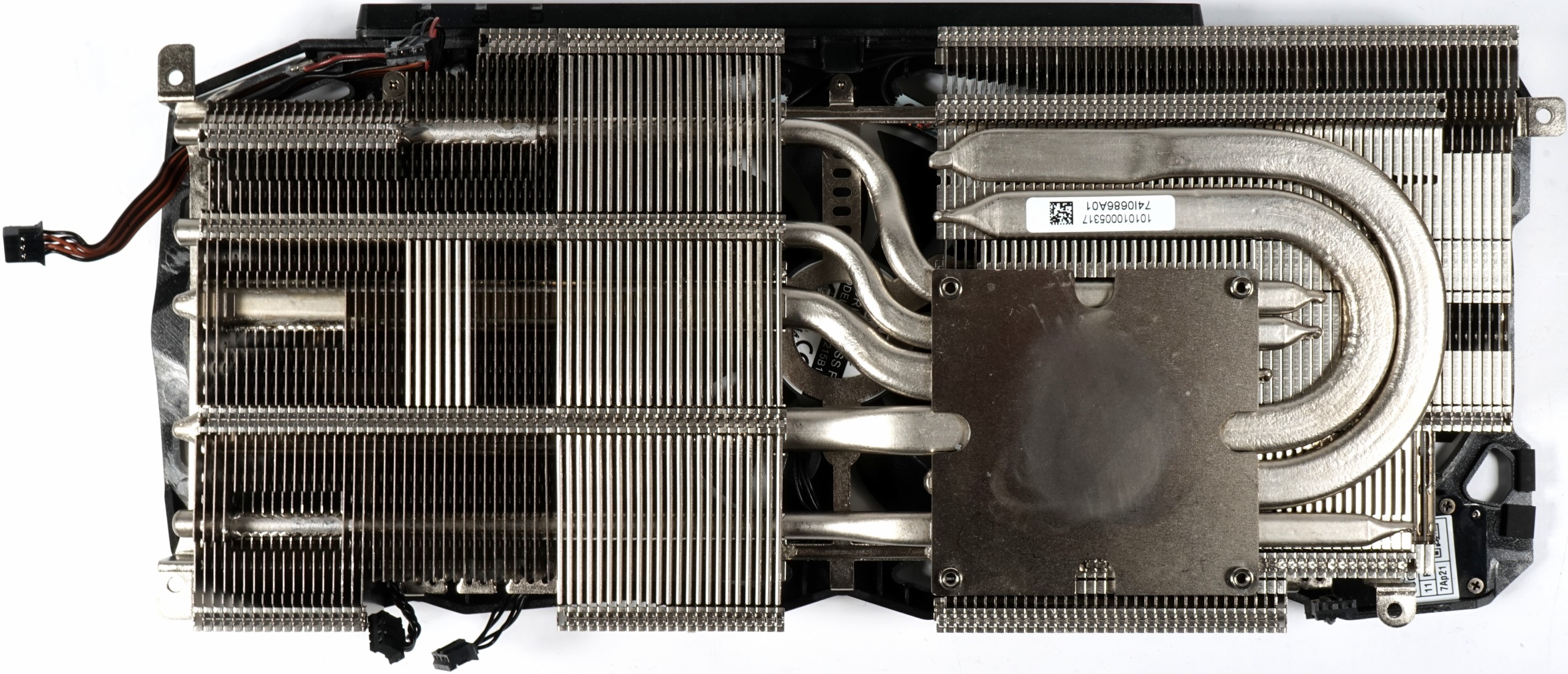

The cooler itself is a pure dual-slot solution, which of course sets physical limits over the possible cooling surface. After all, EVGA has once again managed to design a 300-watt design that still safely controls the resulting waste heat even in the closed housing for at least three working fans. We will see later what noise level you might have to buy this with.

A total of three 8 mm and three 6 mm heatpipes made of nickel-plated composite material ensure the distribution of waste heat from the heat sink to the last lamella. The nickel-plated heat sink carries the pressed heatpipes and at the same time the radiator structure. We also see that the surfaces in the places where the pads are placed by the VRM heat sink have been angled by 90° to form a kind of contact surface.

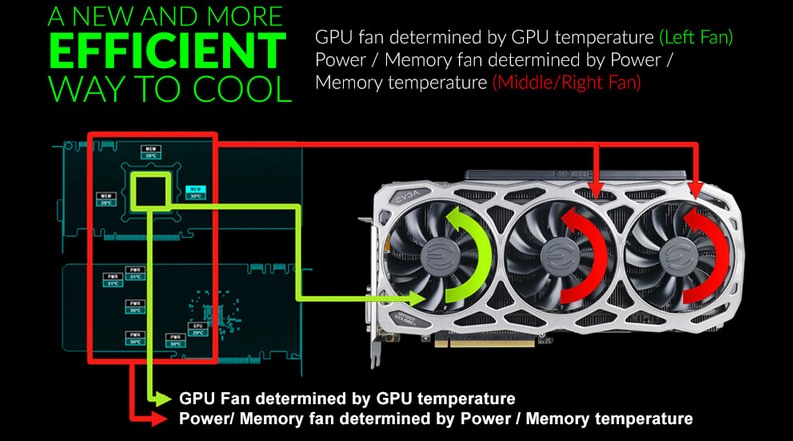

The three fans used, each with a rotor diameter of about 85 mm, are designed for throughput with their 11, rather steeply employed rotor blades per fan. However, we will come back to these fans later when it comes to fan control and speeds. In any case, the temperature-controlled fan control system, which we already know from the EVGA GeForce GTX 1080 FTW2 with the iCX cooler and had already described in great detail there, is interesting. That's why we're just saving ourselves the duplication of the content.

Kommentieren