Uneven and with gradient

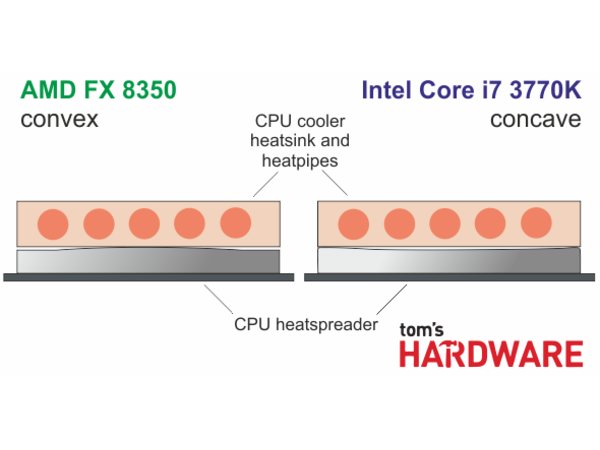

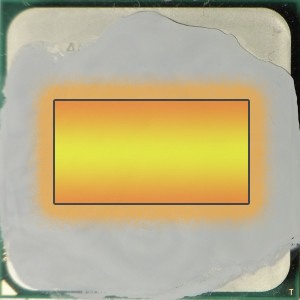

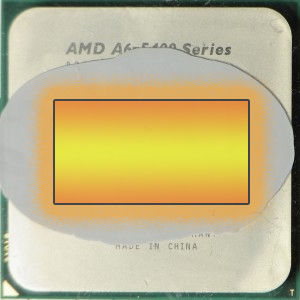

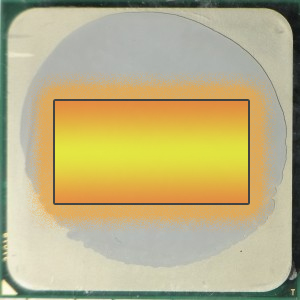

As if the misery as such weren't big enough, the CPU manufacturers put one more on it. After the just mentioned unevenness of the surface, the respective heatspreaders of both manufacturers are anything but flat and flat even in the outer form. This is due to the design and expresses itself (admittedly greatly exaggerated for the clarity here) then as shown in the diagram:

While the area of the hotspot for the AMD CPUs is more outward, i.e. curved towards the radiator floor, for Intel CPUs the edge is more or less slightly higher. Convex (AMD) and concave heatspreaders (Intel) meet with an almost flat radiator floor. Often the handling of the AMD CPUs is easier, because due to the contact pressure of the cooler, the thinnest point (the compressed and pushed away) heat paste automatically results exactly where it is needed in this form. With Intel CPUs you should use a little more paste and above all aim to ensure that the areas of the hotspot get enough paste and that the radiator floor does not make a "hollow cross" with the resulting air inclusion.

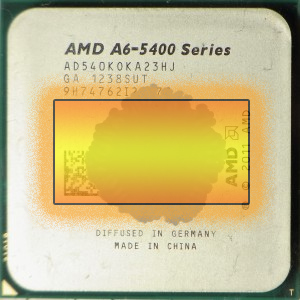

Distribution of the paste under pressure

The animation below clearly shows how the thermal paste moves away to the sides under pressure. I will go into more detail later on the relationship between the fluidity of a paste (i.e. its flow properties, the opposite of viscosity) and the maximum possible contact pressure of the cooler construction used. In general, however, a paste with lower viscosity is much better to handle than a so-called "tough" paste, even at lower pressures, such as those found in Intel's push-pin fasteners.

The rather theoretical information of the manufacturers on thermal conductivity is therefore by no means a measure of the maximum performance achievable in practice in a certain combination of CPU, paste and radiator! The best cooler is no good if the appropriate thermal paste is not selected. Here, too, an unfavourable election can make it even worse than one might ideally gain from the supposed top product!

Philosophers' Controversy – the Method

In principle, it is almost sausage, which one makes as wrong, because every method is really optimal even if the user exactly adheres to the specifications of quantity and optimal consistency of the paste under the concrete conditions and hits, if at all. However, the lubrication of the whole CPU with paste is, as the considerations to the hotspot show us very clearly, with the current CPUs generally rather pointless and outdated. Rather, it is more important to keep a close eye on the specific sequalities of the respective CPU and the radiator floor, as well as the mounting method (possible contact pressure).

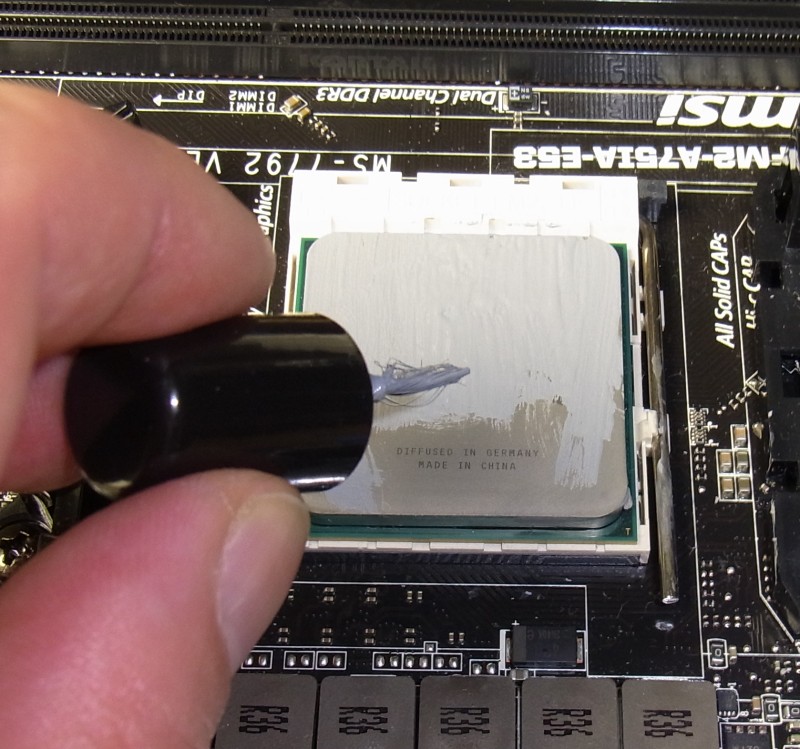

Brushes and strokeable pastes

Stringable pastes, such as the Revoltec Thermal Grease Nano can even be passed with a brush and are by far the easiest to use.

Stringable pastes, such as the Revoltec Thermal Grease Nano can even be passed with a brush and are by far the easiest to use.

However, the silicone content required to obtain low viscosity is usually so high that these products perform worst in practice when measured.

On the other hand, if you use normal, reasonably liquid pastes (such as the already mentioned Arctic MX-2) with a brush, then the covering already becomes much too thick and does not result in an optimal solution.

Blobs, sausage or complete facade paint?

Well, let's leave aside the special case of liquid metal products and ready-made pads and dedicate ourselves to thermal paste as arguably the most commonly used medium.

Well, let's leave aside the special case of liquid metal products and ready-made pads and dedicate ourselves to thermal paste as arguably the most commonly used medium.

From our point of view, the complete chipping of the CPU with paste is far too complex, as well as prone to errors for overdoses and air inclusions. In addition, not every paste can be passed equally well, which in the worst case leads again and again to the tearing up of the resulting film.

Those who struggle with too tough paste and a spatula (or the well-quoted credit card) as here on the graphic, have actually already lost in advance. Of course, you can pull a thin bag over your index finger and gently and thinly rub a thermal paste with a very low viscosity.

But here, too, the risk of mis-dimensioning for the inexperienced is far too high. Those who also rely on powerful pastes, whose viscosity is often very high enough ("tough" pastes), will have no chance of distributing these pamphlet thinly enough without later air pockets.

Strip method: it's all about the sausage

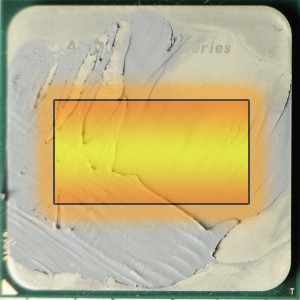

If you look at the position of the Die under the heat spreader, you will surely also come up with the idea of applying the thermal paste exactly in this form. However, you should already dose the right amount, otherwise the paste quickly swells out at the nearest sides. If you then use electrically conductive paste, hardware damage is almost pre-programmed. However, you should apply them a little more carefully than on our example:

|

|

If, on the other hand, the paste is approached a little more sparingly, then the result is quite useful. You don't have to be afraid, because a small part of the heat spreader gets less or maybe no paste, because the absolute edge plays only a minor role in the cooling. If you were to use a cooler with its own backplate and a higher contact pressure at the optimal quantity, the distribution would also be more extensive. As a recommendation, it is recommended: more liquid pastes with high fluidity / low viscosity and good radiator attachment.

|

|

We're cracking ourselves to the optimum

In principle, the blob or Blob method suitable for beginners and professionals alike. In addition, as long as you use good coolers with high contact pressure, even the tougher pastes can be used without any problems. However, here too contact pressure and viscosity determine the amount of paste to be used. Of course, one must not put such a blob too small out of fear, because then nothing swells over, but one does not reach the required spread and distribution. In this case, the chip under the heat spreader simply gets too hot.

|

|

The quantity can be estimated approximately, considering that a high contact pressure of a screw-in cooler requires less paste than, for example, a mounted and locked heat sink (AMD-Boxed) or one with simple clips (Intel Boxed with push pins). The tougher a paste is, the higher the achievable contact pressure of the cooler and the more paste you have to use. In any case, the "more" should be very low.

|

|

Here we come relatively close to the optimum, because a thin layer that optimally covers the surface of the Die under the heatspreader is always better than a consistently thicker layer down to the last edge. Who knows how big a pea is, should beware of the flowery paraphrases of an "heir-sized" clatter. Depending on the required quantity, 2-4 mm in diameter are sufficient, 5 mm and more are already too much. Thus, we would probably have arrived with a dry, quite small lens.

In the end: Don't worry!

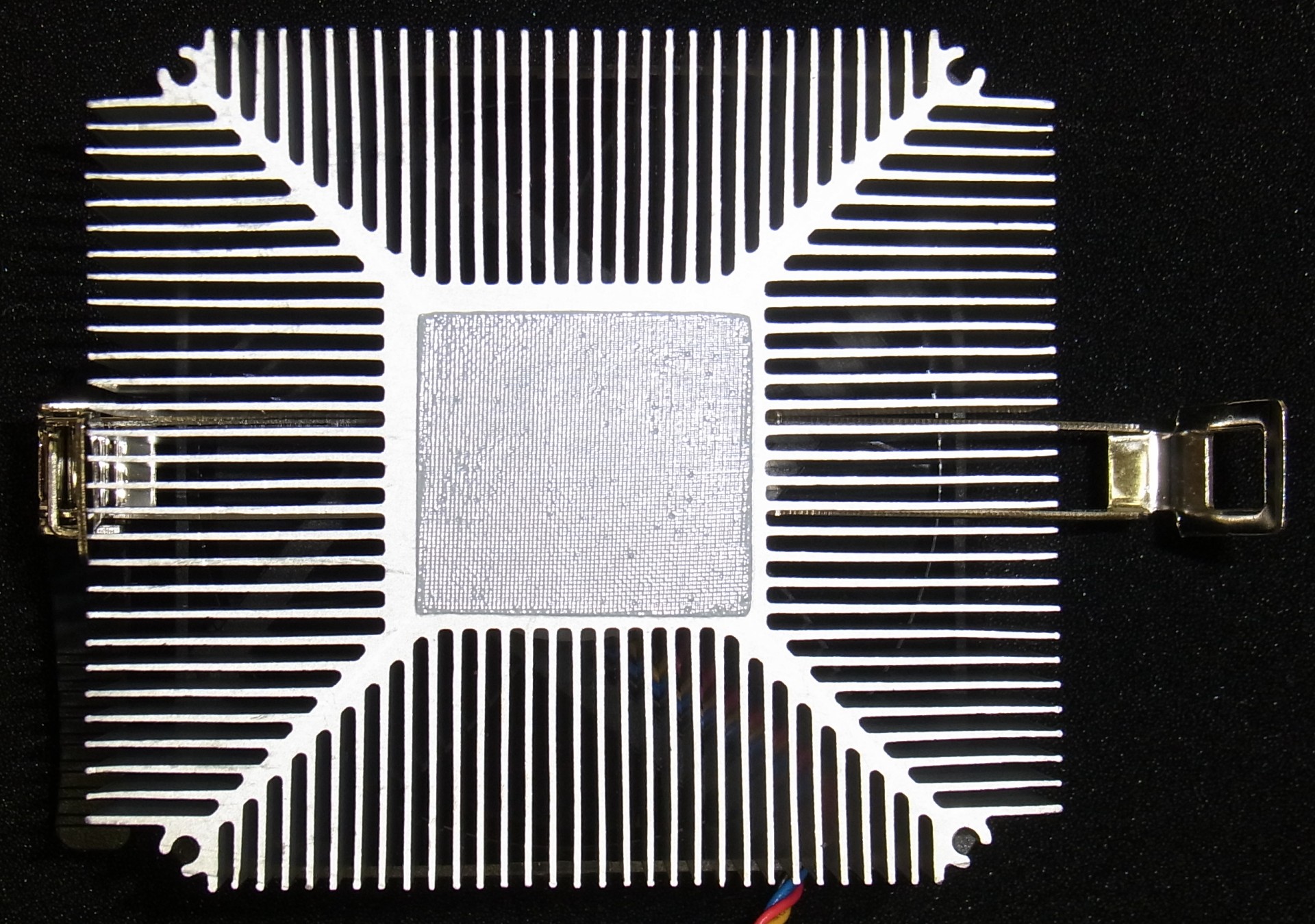

The fact that the manufacturers of the CPUs probably see this the same way with the distribution of the paste can be clearly seen in many enclosed (boxed) coolers. For example, AMD used many CPUs and APUs by first hand only approx. 2/3 of the heat spreader surface at all for contact with the heat sink. The paste applied in a screen-pressure-like process is relatively tough and hardly spreads further outwards, since the pressure duck of the boxed cooler is quite low. Nevertheless, manufacturers rely on this solution!

So why are we bringing this aluminium dumpling into play in the first place? We just want to take away the fear of the newcomers a little bit, because we also had our abdominal pain the first time, if we are to be honest. Sure, that was almost two decades ago, but respect for the matter has remained. The most appropriate is a mixture of mature consideration, necessary composure and healthy caution. Then you can't do anything wrong.

- 1 - Einführung und Übersicht

- 2 - Grundlagen: Heatspreader und Heatsink

- 3 - Wärmeleitpaste: Funktion und richtiges Auftragen

- 4 - Sonderfall Grafikkarte

- 5 - Sonderfall Wärmeitpads und mögliche Verbesserungen

- 6 - Flüssigmetall und die Grenzen

- 7 - Testsetup und Messmethoden

- 8 - Testergebnisse: Wasserkühlung

- 9 - Testergebisse: Lüftkühlung (großer Turmkühler)

- 10 - Testergebisse: Lüftkühlung (Boxed-Kühler)

- 11 - Testergebisse: Grafikkarten-Kühlung (GPU)

- 12 - Testergebnisse: Viskosität

- 13 - Testergebnisse: Verarbeitung und Anwendungssicherheit

- 14 - Zusammenfassung und Fazit

Kommentieren