For many older Intel CPUs I have still added measurements in the image gallery, which demonstrate more or less strongly the concave deformation of the IHS. This varies from model series to model series and, of course, when using solder or TIM. However, since it turns out similar in many respects, I’ll limit myself to more recent CPU samples. By the way, this also applies to the older AMD CPUs.

Intel’s Core CPUs from 6xxx, 7xxx, 8xxx to 9xxx for the consumer

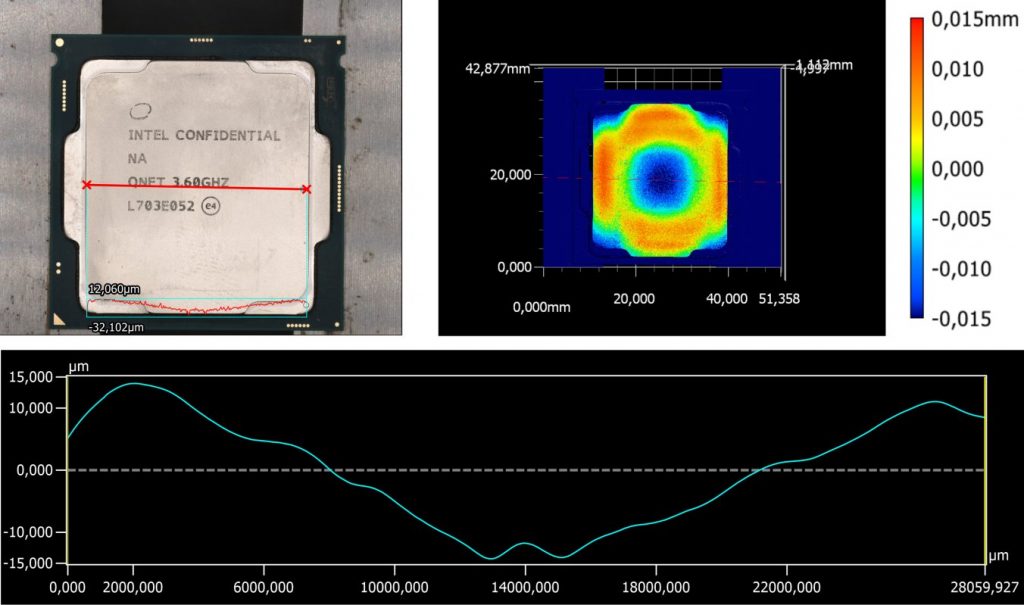

I admit the page title is a bit provocative, but I could have easily written downhill. Of course, I am only referring to the surface of the IHS and not to the sensitivities of the company, which is not what this is about. Intel’s IHS are concave, even after a proper mount or burn-in, and they remain so forever and ever. Now let’s look at the IHS, which is representative of the 7th, 8. and 9. Generation and with a black hole yawning in the middle. This is where the lack of a proper solder becomes painfully apparent:

Depending on the direction of the measurement, the IHS disappears in the middle by a good 0.02 to 0.03 mm. That doesn’t sound like much either, but it is. Because while a flat cooler base already sits firmly on the edge, there is always an extremely thick layer of thermal paste left over the hotspot. The thicker the layer, the greater the thermal resistance, because this increases proportionally to the thickness of the layer. For these CPUs, a convex and conical outward curved shape of the cooler bottom definitely makes deeper sense!

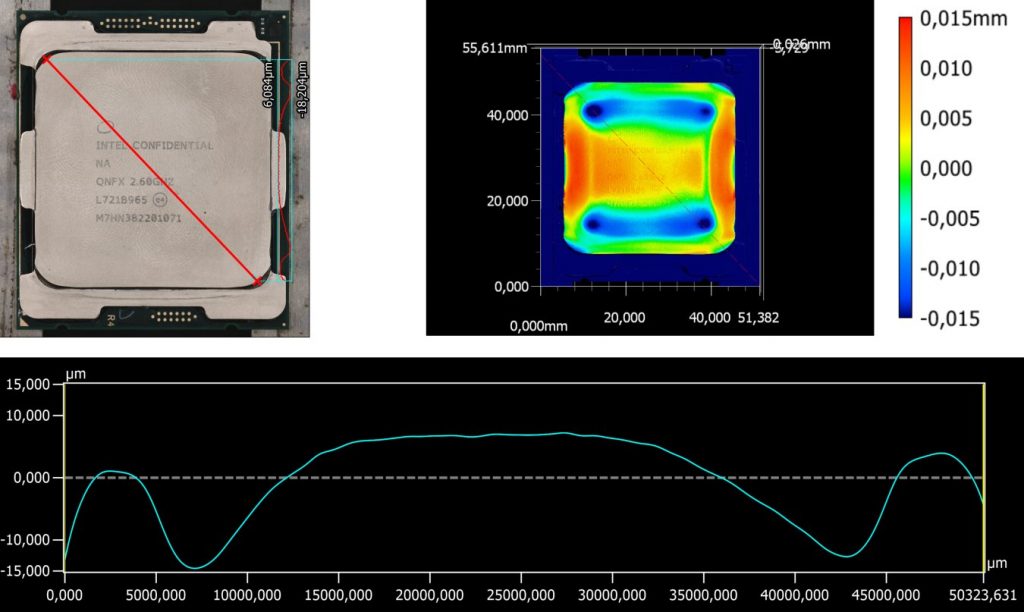

One can only surmise that this “hole” is at the current 10. Generation and the upcoming 11. Generation becomes a little less prominent, because the IHS above the die is much thicker and you also use solder again instead of TIM. Trying a straight edge on a 10900K might well confirm that. So you should start at 10. In the second generation with convex outwardly curved radiators, you should be a bit more careful again, because the effect would then turn into a negative and it could get hotter instead of cooler.

The enthusiast platform from 7xxxx to 9xxxx

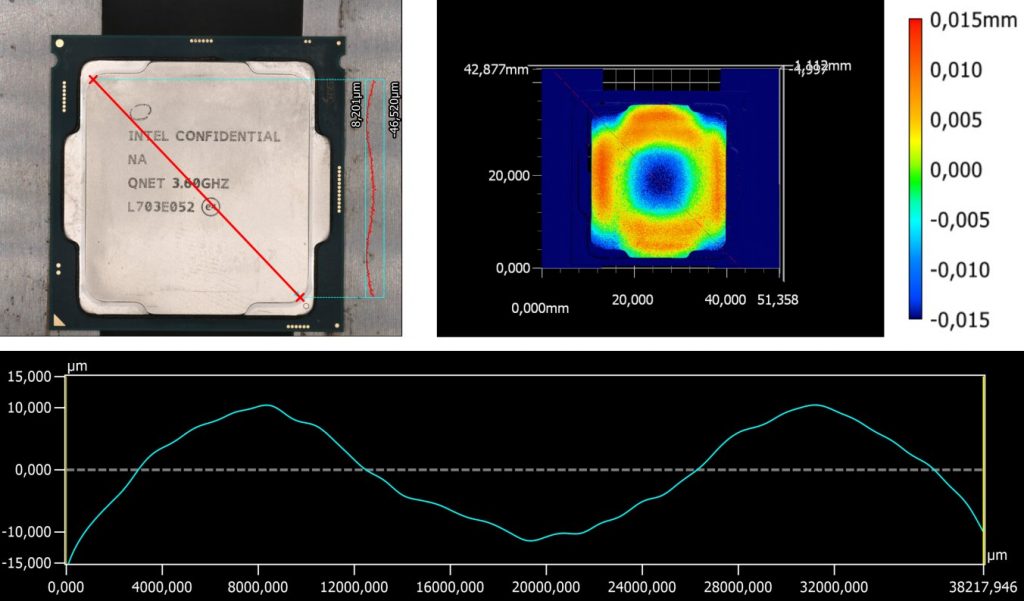

I can only measure what I have, unfortunately, so the 10 model range will have to be left out. However, I was able to carry out plausibility tests on several systems, which once again confirm the measurement listed below as an example. The largest deviation here is shown by the diagonal measurement with almost 0.025 mm:

What we also see is the “supporting force” of the solder between the very large die and the IHS. Next to the die, a real uphill and downhill ride begins towards the edge. So less paste in the middle and more of it in the two seepage pits next to the die, then it fits again.

Preview of the follow-ups

First of all, starting tomorrow, I will present the still measured AMD and Intel CPUs each in picture galleries. There we have an overview of all measurement data, surfaces and curvatures. So it remains exciting!

Kommentieren